Settling tank for sewage treatment

A technology of sewage treatment and sedimentation tank, which is applied in the direction of flocculation/sedimentation water/sewage treatment, settling tank, feeding/discharging device of settling tank, etc. problems such as mud, to achieve the effect of reducing concentration, ensuring treatment effect and improving sedimentation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

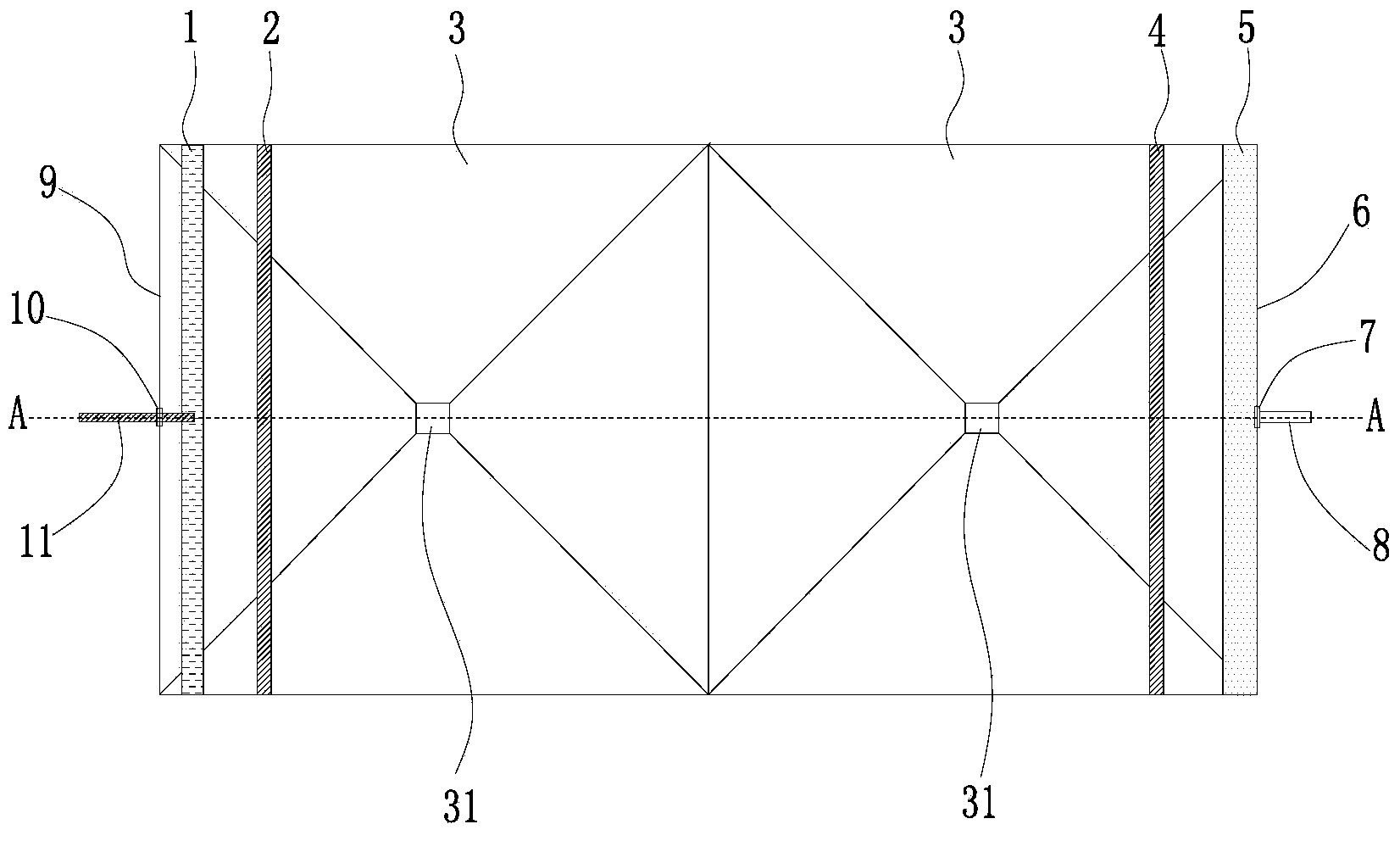

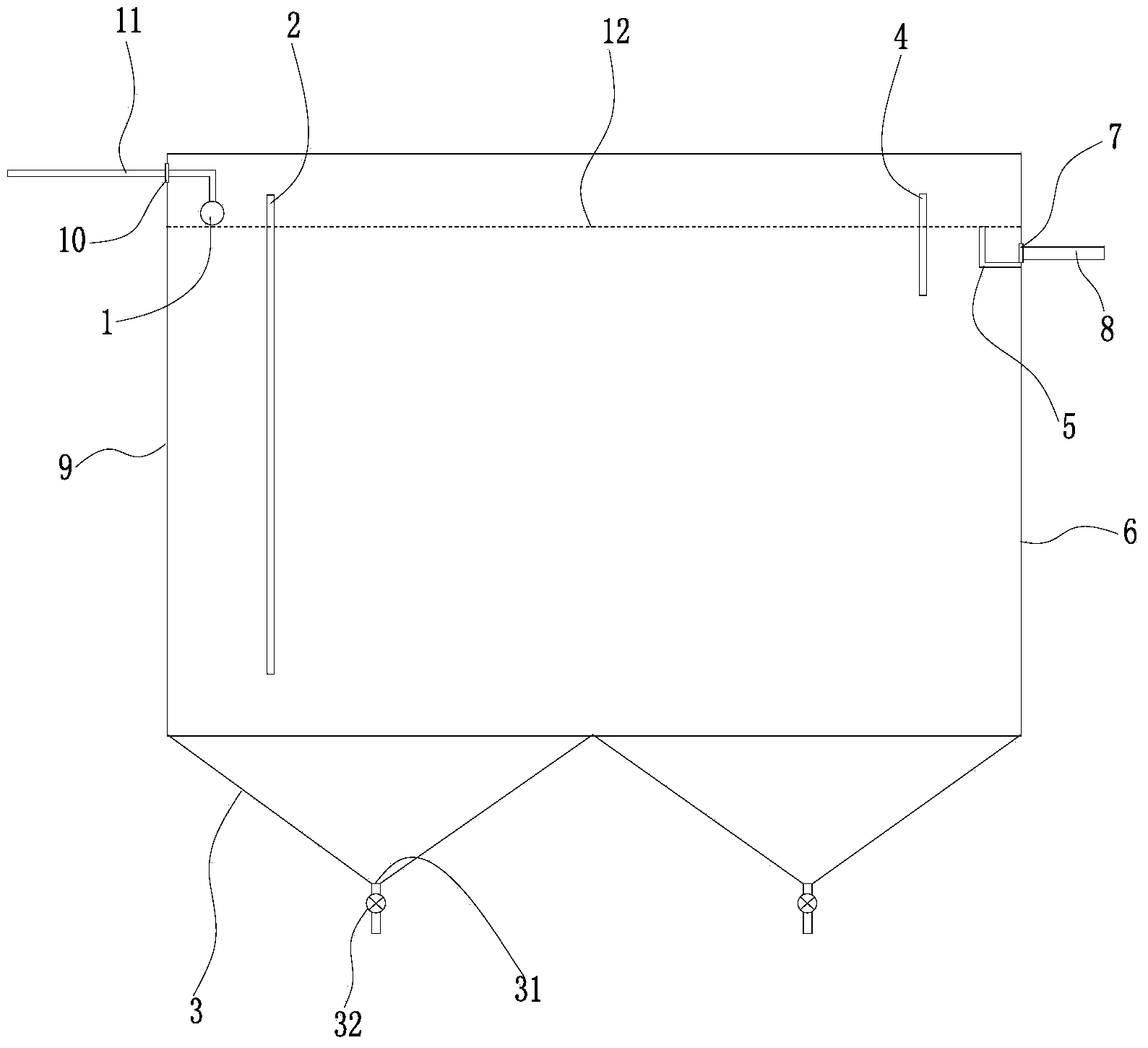

[0021] refer to Figure 1-2 A settling tank for sewage treatment provided in this embodiment includes a tank body and a conical sludge bucket 3, and a water inlet 10, a water outlet 7, a first baffle plate 2, Second baffle plate 4, water inlet area, sedimentation area, water outlet area, water distribution pipe 1, water inlet pipe 11 and water outlet weir 5.

[0022] The pool body is a cube with a height of 2m. Two conical sludge hoppers 3 are arranged side by side at the bottom of the pool body, and the upper edge of the conical sludge hopper 3 is fixedly connected with the bottom of the pool body, so that the pool body and the two conical sludge hoppers 3 constitute a storage tank. Storage space for sewage and sludge. A row of mud outlets 31 are respectively arranged at the bottom of the conical sludge hopper 3, and a mud discharge valve 32 is installed at the mud discharge outlet 31. The sludge is discharged in time or flows into other institutions, such as the sludge re...

Embodiment 2

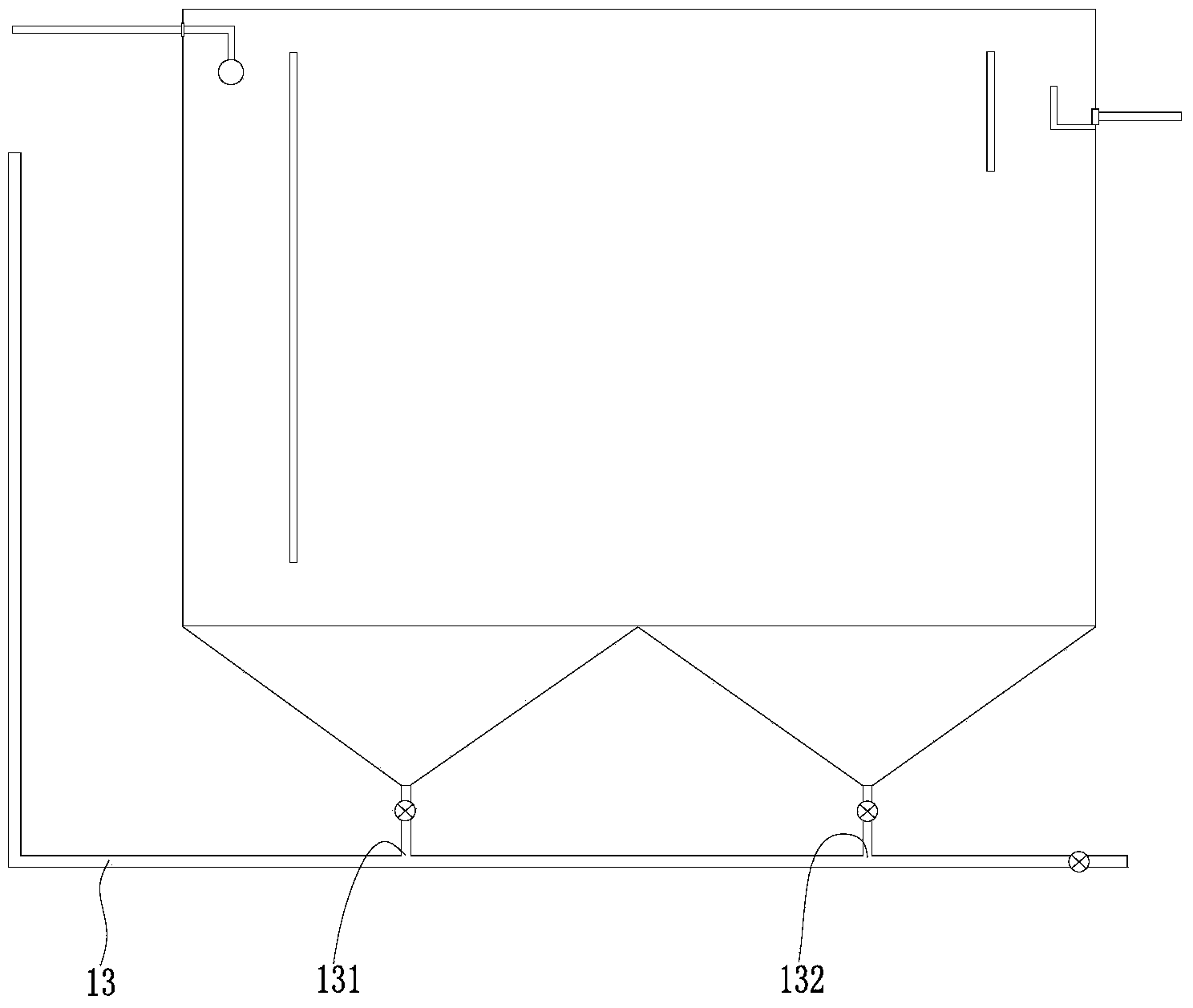

[0027] like image 3As shown, the sedimentation tank for sewage treatment provided in this embodiment has basically the same structure as that in Embodiment 1, except that a sludge return mechanism 13 is provided at the bottom of the tank. The sludge return mechanism 13 includes a first sludge inlet 131 and a second sludge inlet 132, and the first sludge inlet 131 and the second sludge inlet 132 are respectively connected to two conical sludge hoppers through pipes. The two sludge inlets are finally joined together through pipelines to form a main pipeline to transport sludge to other treatment tanks (such as pre-denitration tanks). The sludge return mechanism 13 used in this embodiment is an air-lift sludge return mechanism, and in other embodiments, other forms of sludge return mechanisms can also be used.

[0028] In other embodiments, the distance between the bottom of the second baffle and the highest liquid level of the pool body can also be set to be 15-30 cm, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com