Device for drying compressed air and regeneration method

A technology of compressed air and compressed air flow, applied in the field of dry devices, can solve problems such as loss of energy and time, and achieve improved desorption or cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

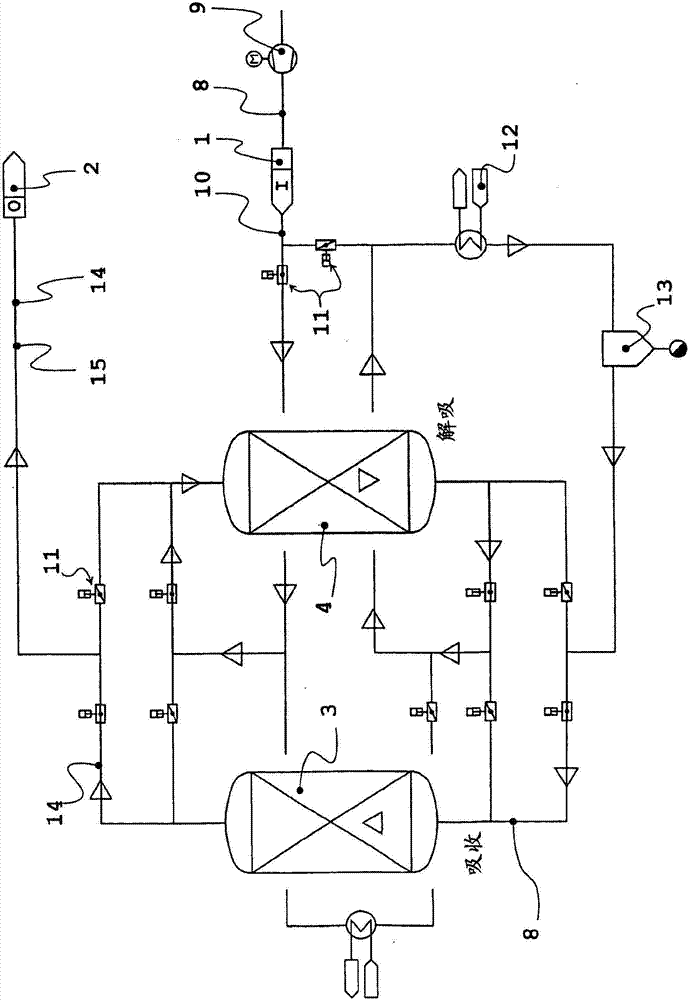

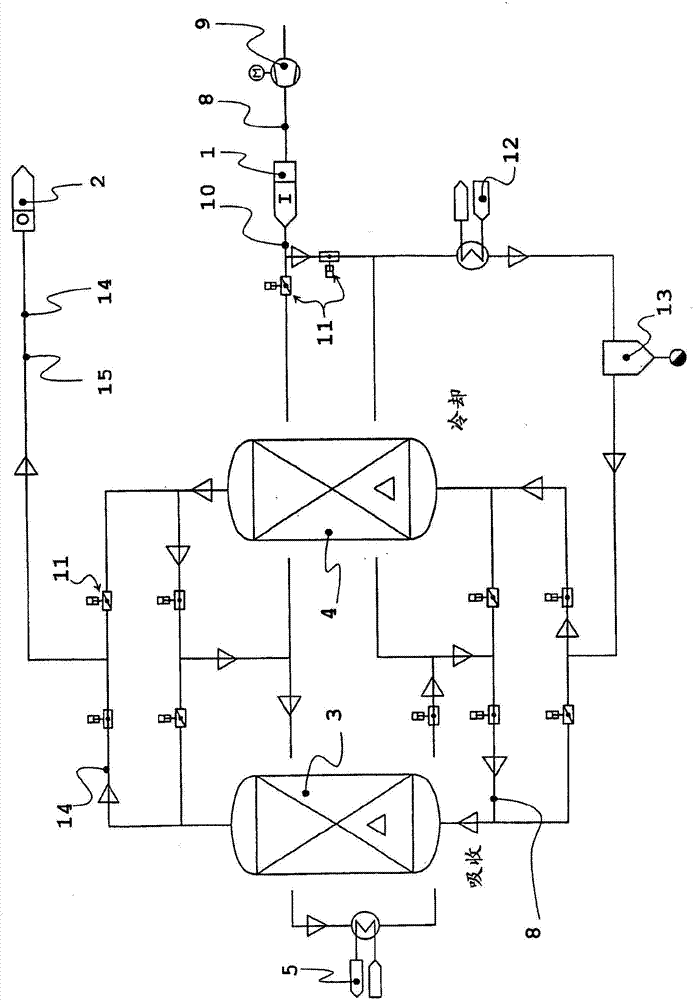

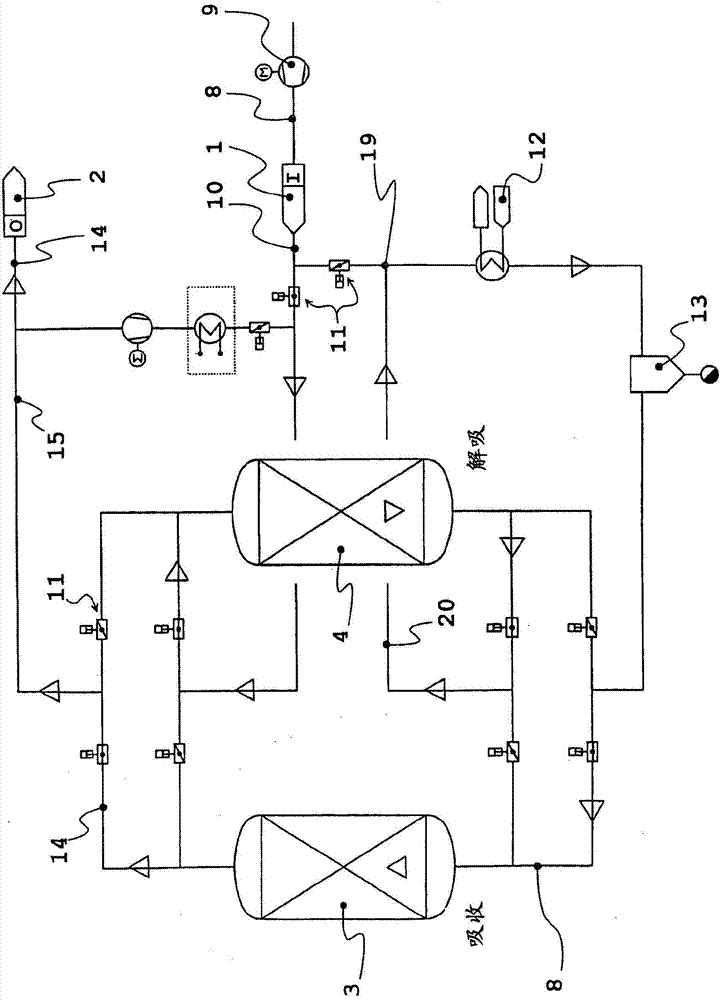

[0030] image 3 , 4, 5 and 6 show in different stages a first embodiment of the device for drying compressed air according to the invention. Moist compressed air 8 (compressed from ambient air by a compressor 9 not belonging to the device) enters the device through inlet 1 . The compressor 9 is not equipped with a subcooler, so that the incoming moist compressed air 8 is warmer than the ambient air. An inlet line 10 branches off directly behind the inlet 1 and can be connected on both sides to each of the two parallel absorption containers 3 , 4 by means of a plurality of adjustment mechanisms 11 .

[0031] exist image 3 In the operating situation shown, the absorption vessel 3 on the left is in the absorption phase, and the absorption vessel 4 on the right is in the regeneration phase, more precisely in the desorption phase. For the desorption, the heat of the still-to-be-dried compressed air 8 is first conducted along the intake line 10 through the right-hand absorption v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com