Glass tube internal heating type electromagnetic induction airflow heating device

An electromagnetic induction and internal heating technology, applied in induction heating, coil devices, etc., can solve the problems of poor thermal conductivity, high heat dissipation rate, and large volume of glass, and achieve rapid temperature adjustment, small volume, and high heating efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

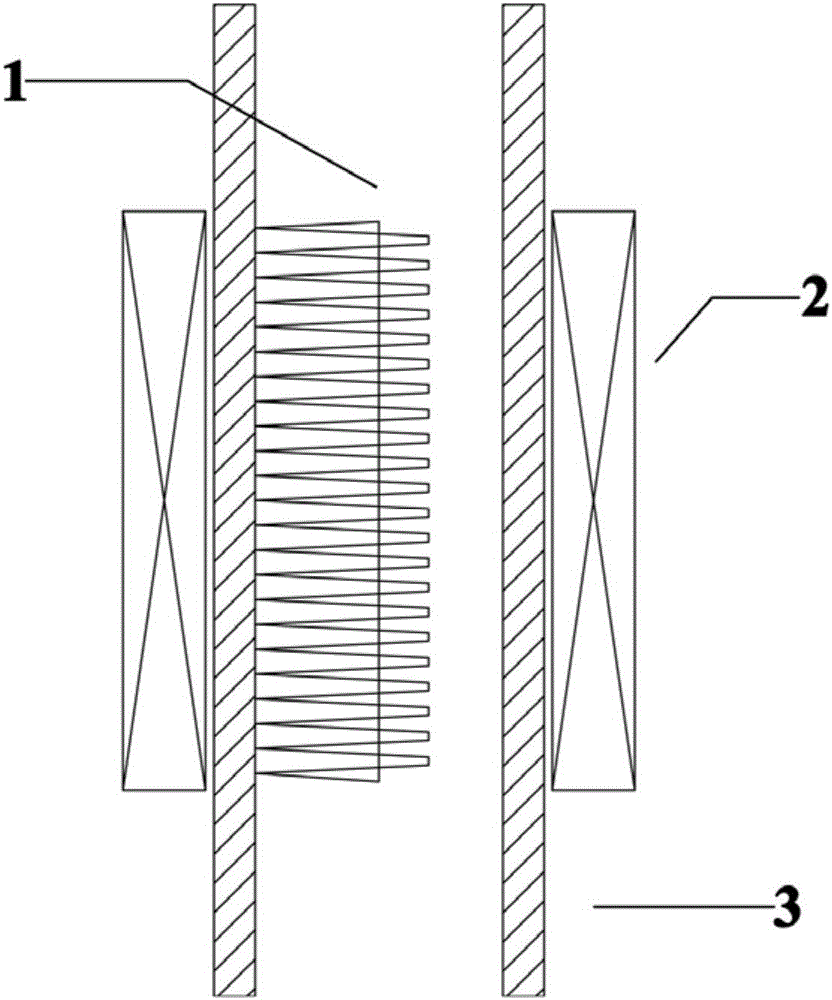

[0028] An internal heating type electromagnetic induction airflow heating device in a glass pipeline, such as figure 1 As shown, the device is composed of a triangular spiral wire circuit 1, an electromagnetic coil 2, a quartz glass tube 3, an adjustable high-frequency AC power supply or a pulsed DC power supply.

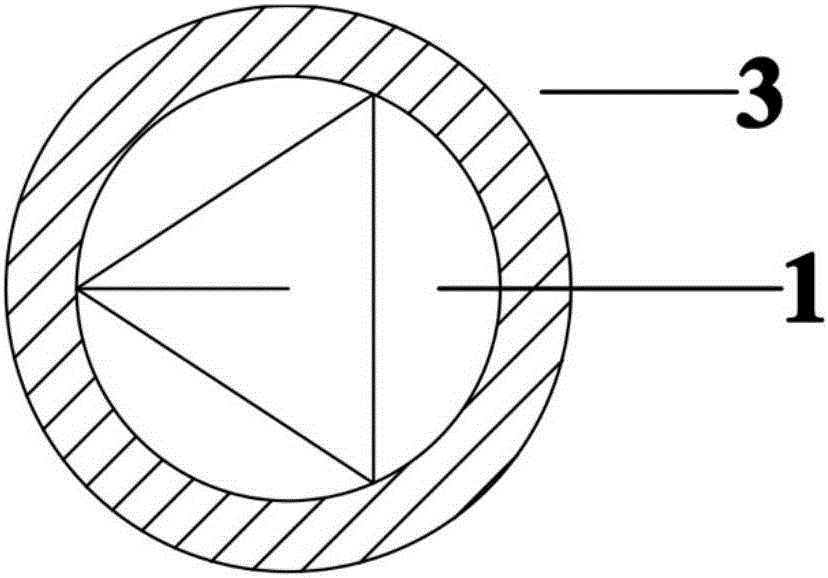

[0029] The triangular helical wire loop 1 can be made of platinum wire or nickel wire. The two ends of the helix are turned back and connected along the center line to form a loop. The number of layers of the helical loop is determined according to the heating temperature requirement and the electromagnetic field strength calculation. Such as figure 2 As shown, the apex of the triangular helical wire loop 1 is in contact with the inner wall of the quartz glass tube 3 . The electromagnetic coil 2 is connected with an adjustable high-frequency AC power supply or a pulsed DC power supply.

[0030] The electromagnetic coil 2 generates an alternating magnetic field or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com