Temperature-sensing pressure-sensing anti-explosion device

An explosion-proof device, temperature sensing technology, applied in chemical/physical/physical-chemical processes, chemical instruments and methods, control/regulation processes, etc., can solve problems such as low safety factor and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

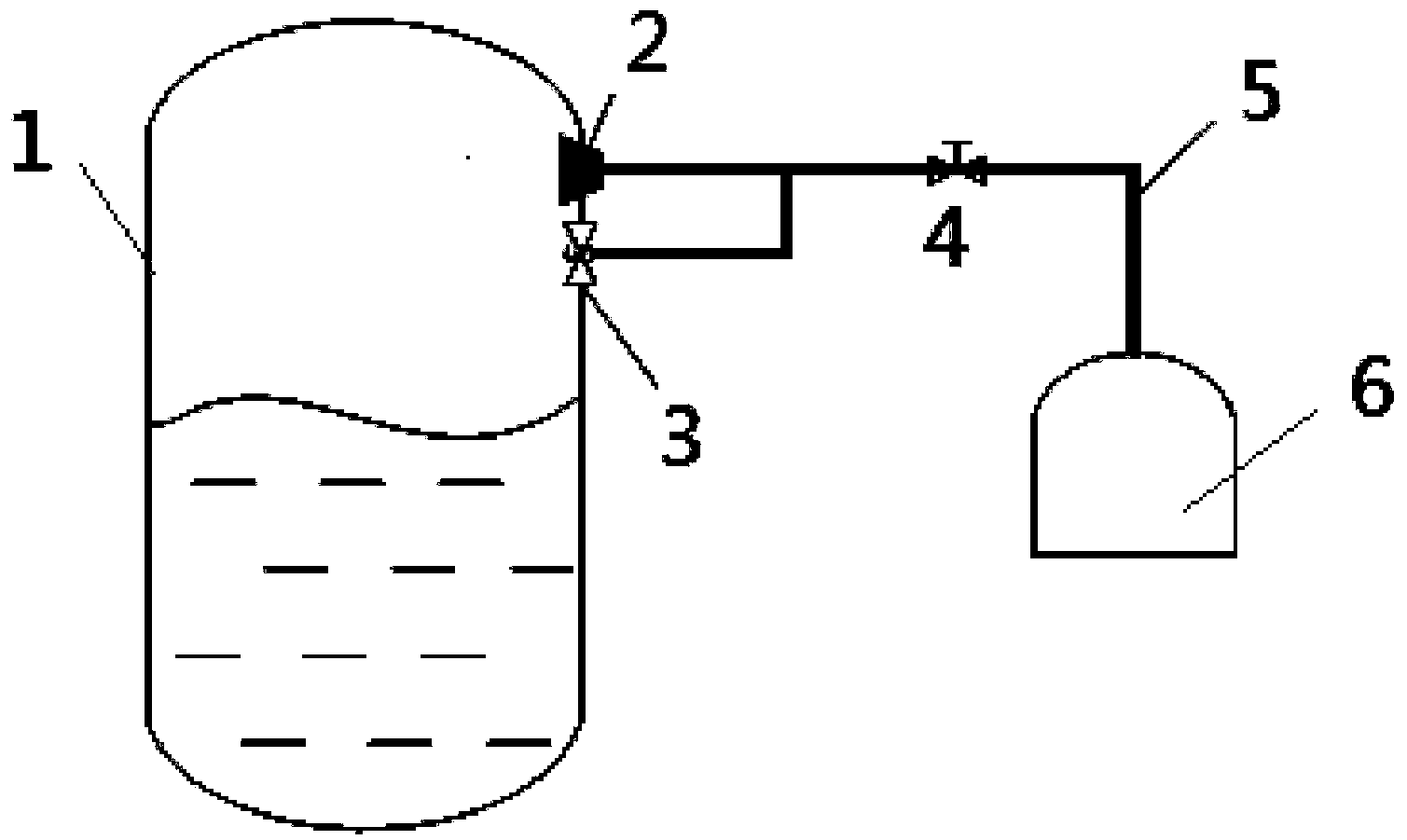

[0016] in such as figure 1 In the device, the bursting disc (3) and the fusible plug (2) are installed on the wall of the reactor (1), and it is characterized in that the bursting disc (3) and the fusible plug (2) respectively pass through the pipeline in parallel It is connected with the pressure relief pipeline (5), and the other end of the pressure relief pipeline (5) is connected with the buffer container, and the pressure relief pipeline (5) is provided with a control valve (4).

[0017] The bursting disc (3) is a positive arched bursting disc, and the fusible plug (2) has a tapered hole on the plug body to fill the fusible alloy. The fusible alloy is made of bismuth, lead, tin and cadmium, etc. Alloys made of metal elements with low melting points. The melting point of the fusible alloy can be achieved by adjusting the content of low-melting metal elements according to the critical temperature that may lead to overheating. When the temperature in the reactor (1) reache...

Embodiment 2

[0019] According to the conditions described in Example 1, only the bursting disc (3) is a reverse arched bursting disc, and the plug body of the fusible plug (2) has stepped holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com