Automatic powder spraying system

A powder spraying and automatic technology, applied in spray booths, spraying devices, liquid spraying equipment, etc., can solve the problems of uneven spraying and difficulty in evenly distributing the surface of the workpiece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings.

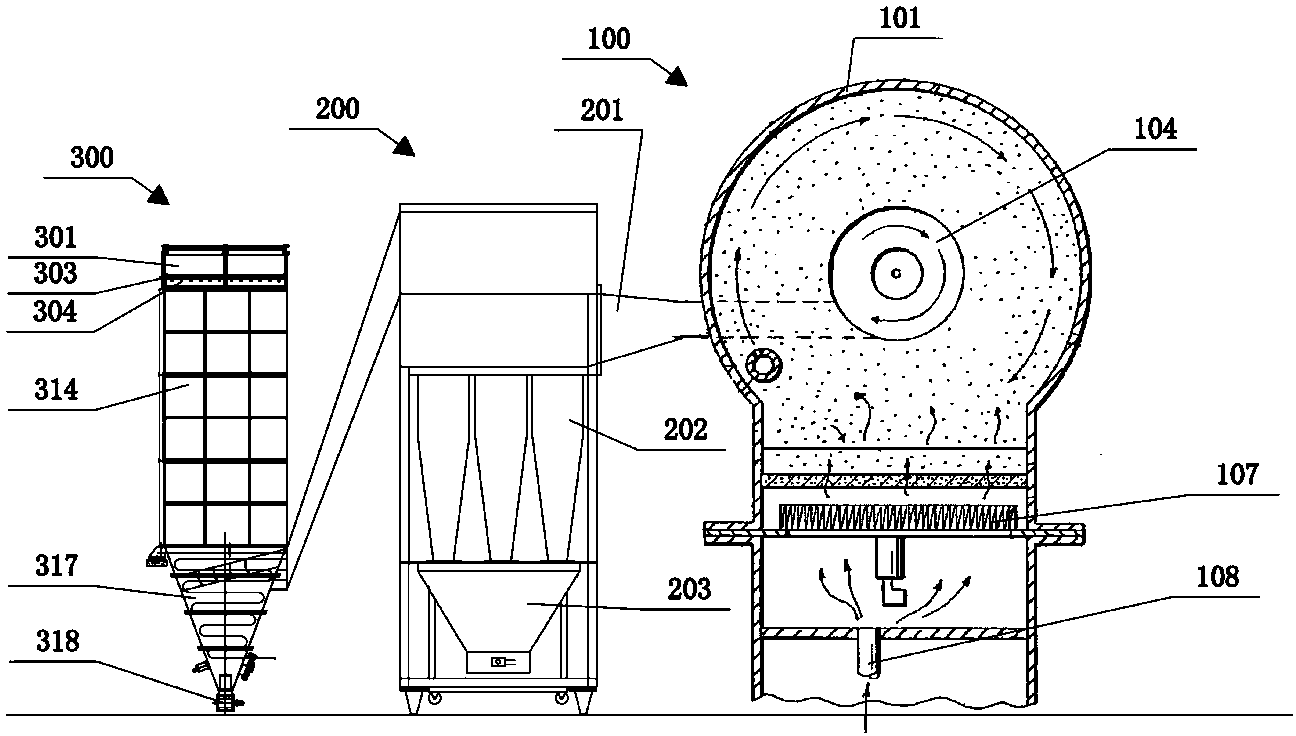

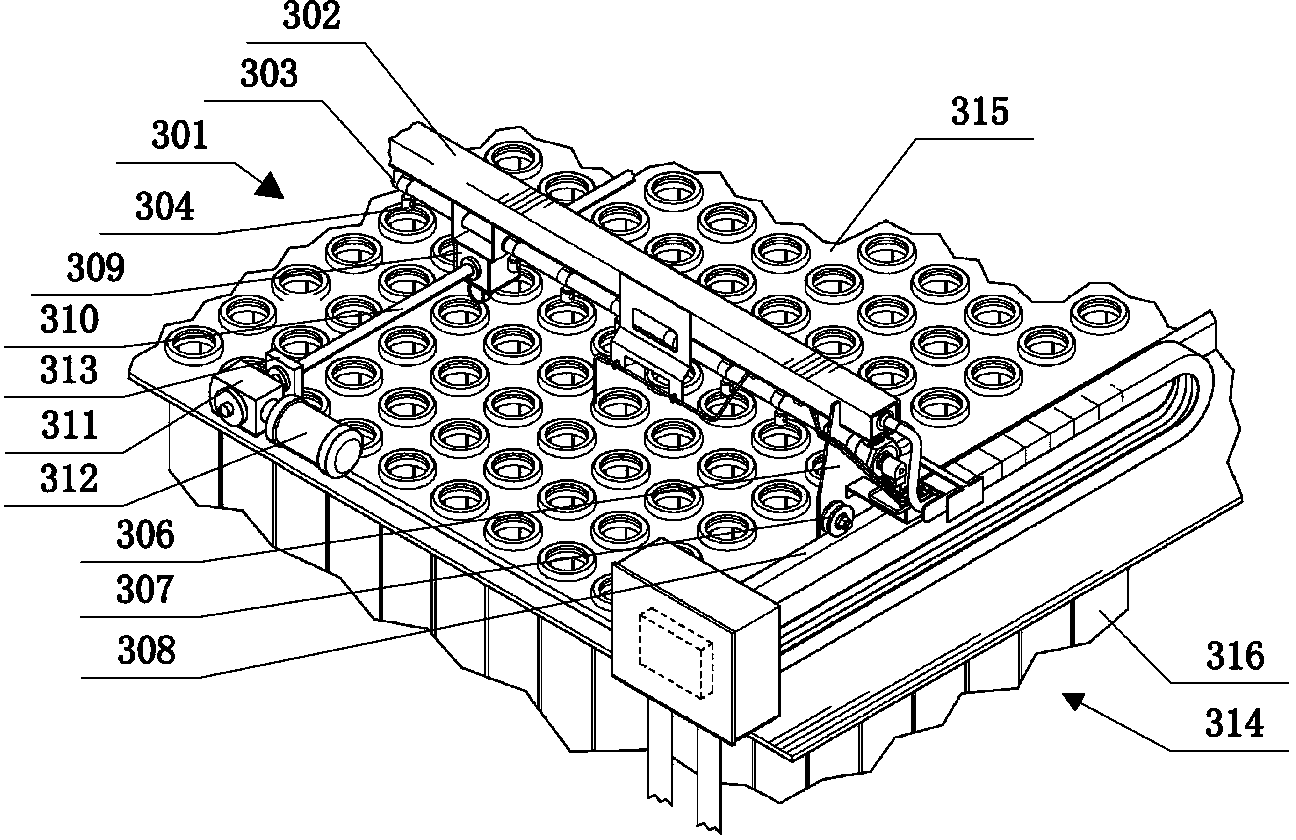

[0020] The automatic powder spraying system includes a spray bin 100 , a multi-pipe cyclone separator 200 and a filter 300 ; the input end of the multi-pipe cyclone separator 200 is connected with the spray bin 100 , and the output end is connected with the filter 300 .

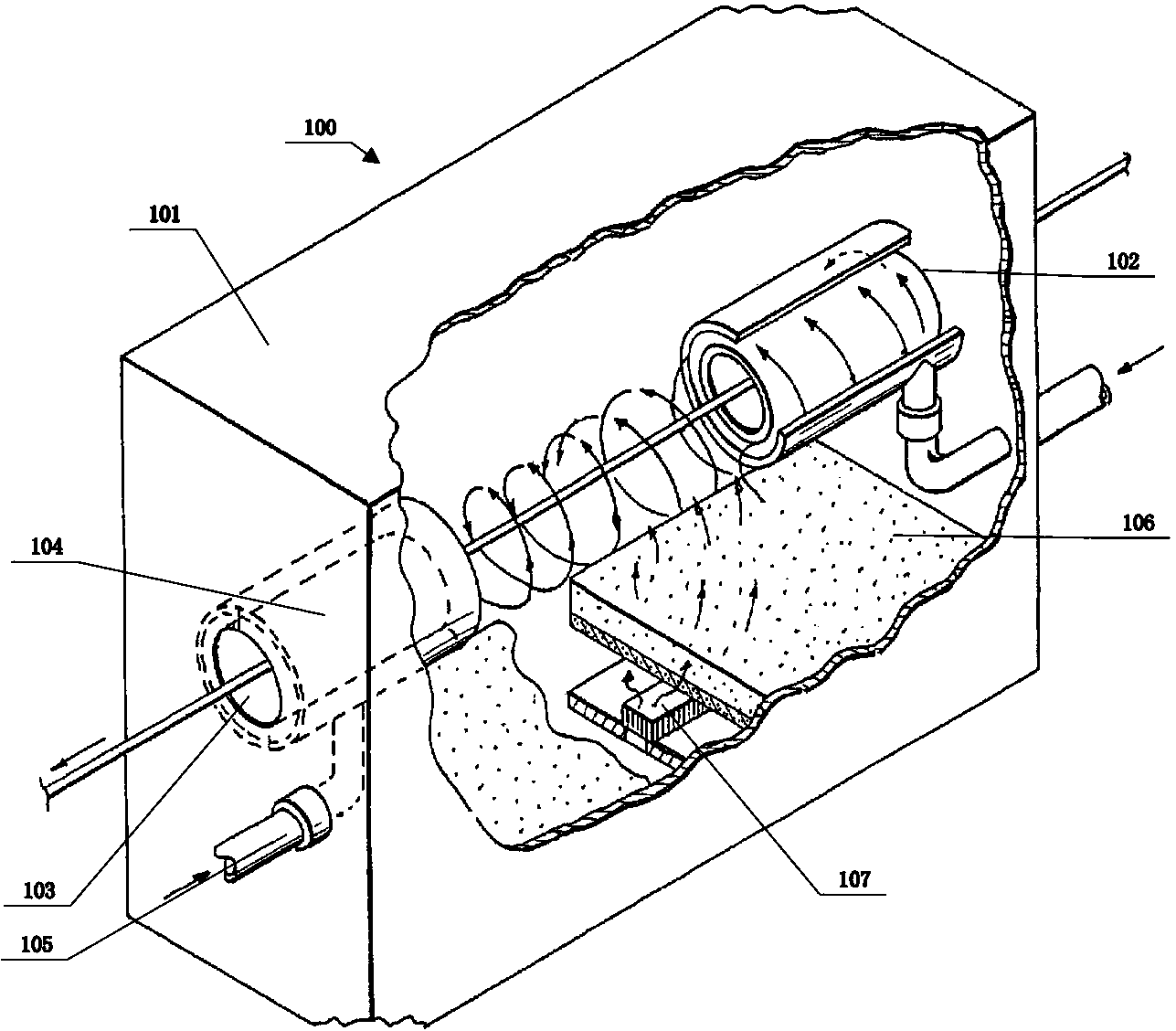

[0021] The spray tank 100 includes a tank shell 101, and two ends of the tank shell 101 are respectively provided with a material inlet 102 and a material outlet 103. Both the feed inlet 102 and the discharge outlet 103 are equipped with a screw generator 104 . The spiral generator 104 includes an outer shell and an inner shell; the inner shell and the outer shell are coaxial. The workpiece penetrates the inner casing of the helical generator 104 . The shell is provided with a powder inlet pipe 105 . The powder inlet pipe 105 communicates with the powder bin.

[0022] The powder in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com