High-efficiency and precise machining method for screw holes of lifting rings in plastic molds

A technology of precision machining and lifting ring screw, which is applied in the field of high-efficiency precision processing of plastic mold lifting ring screw holes, which can solve the problems of insufficient precision, easy loosening and falling off, safety hazards of tap tapping, etc., and achieve high shape and position tolerance precision, internal thread The effect of smooth surface and shortened processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

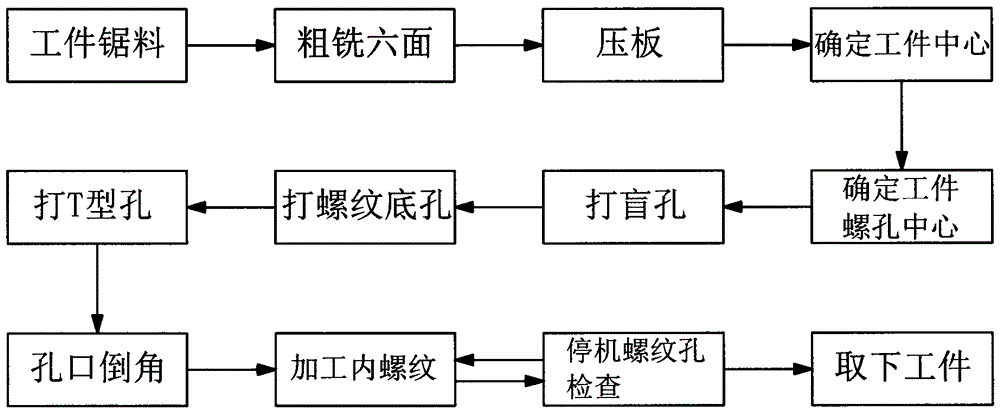

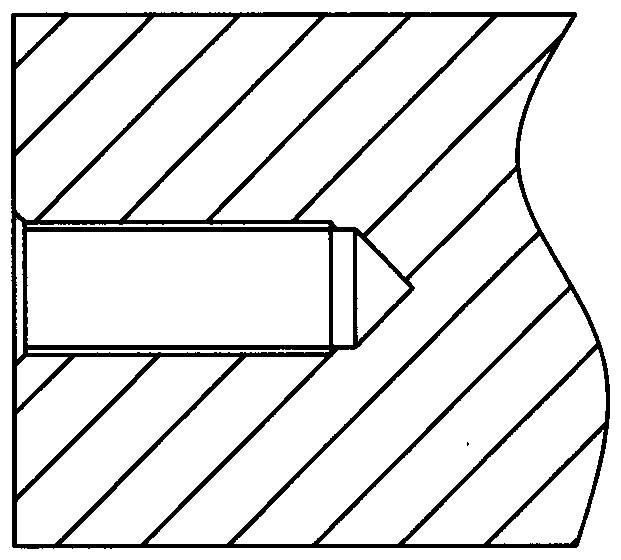

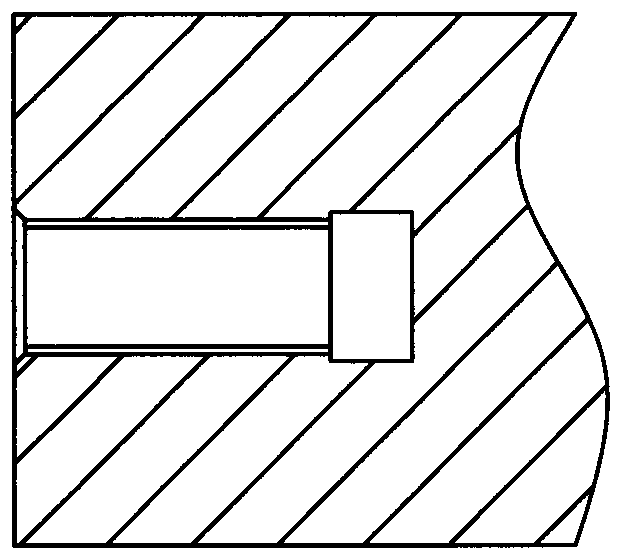

[0031] refer to figure 1 , figure 2 and image 3 As shown, the present invention is a high-efficiency and precise machining method for screw holes of plastic mold lifting rings. The technological process of the method is as follows: workpiece sawing, rough milling six sides, pressing plate, determining the center of the workpiece, determining the center of the screw hole of the workpiece, and drilling blind holes , drilling threaded bottom holes, drilling T-shaped holes, hole chamfering, processing internal threads, stopping the threaded hole inspection, and removing the workpiece; the workpiece sawing material is the machining allowance of each process after it is reserved according to the size of the drawing , using a sawing machine to intercept a rectangular material steel plate for making a mold from a large raw material steel plate; the drawing is an exploded view of the engineering details of the mold product;

[0032] The rough milling of the six sides is based on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com