Motor sweeper cab

A technology for cabs and cleaning vehicles, which is applied in the field of vehicle cabs, and can solve problems such as the influence of the driver's line of sight and field of vision, narrow lighting area, and inability to guarantee the adhesion surface and adhesion force, so as to increase safety and easy identification, increase The effect of contact area and increasing the lighting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

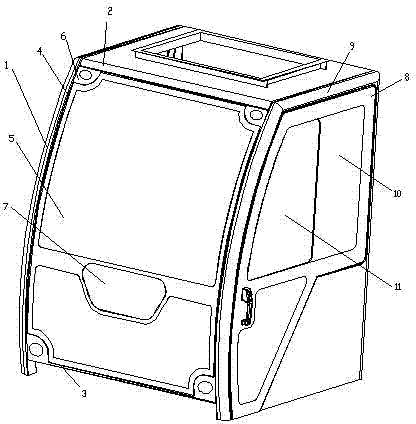

[0013] A kind of sweeper cab, it comprises front windshield panel 1, car door panel and top plate, described front windshield panel 1 comprises front frame, curved windshield glass 5 and illuminator installation panel 7, and described front frame is made of The top strip 2, the bottom strip 3 and two arc-shaped side strips 4 are formed. The top strip 2, the bottom strip 3 and the side strips 4 are provided with interconnected grooves for the four sides of the arc-shaped windshield 5 to be inserted. The windshield 5 is connected and fixed with the front frame through the groove, and the four corners of the front and back of the front frame are respectively provided with fan-shaped pressing plates 6, and the four corners of the described pressing plate 6 are connected and fixed with the windshield 5; The car door panel includes a side frame and a car door 8, and the upper side and the side of the car door 8 are respectively provided with a protective plate 9 connected to the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com