Candy sorting device of packaging machinery

A technology for packaging machinery and sugar management, applied in packaging, packaging protection, transportation and packaging, etc., can solve the problems of high manufacturing and replacement costs, affect efficiency, inconvenience, etc., achieve low noise, improve work efficiency, and reduce wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

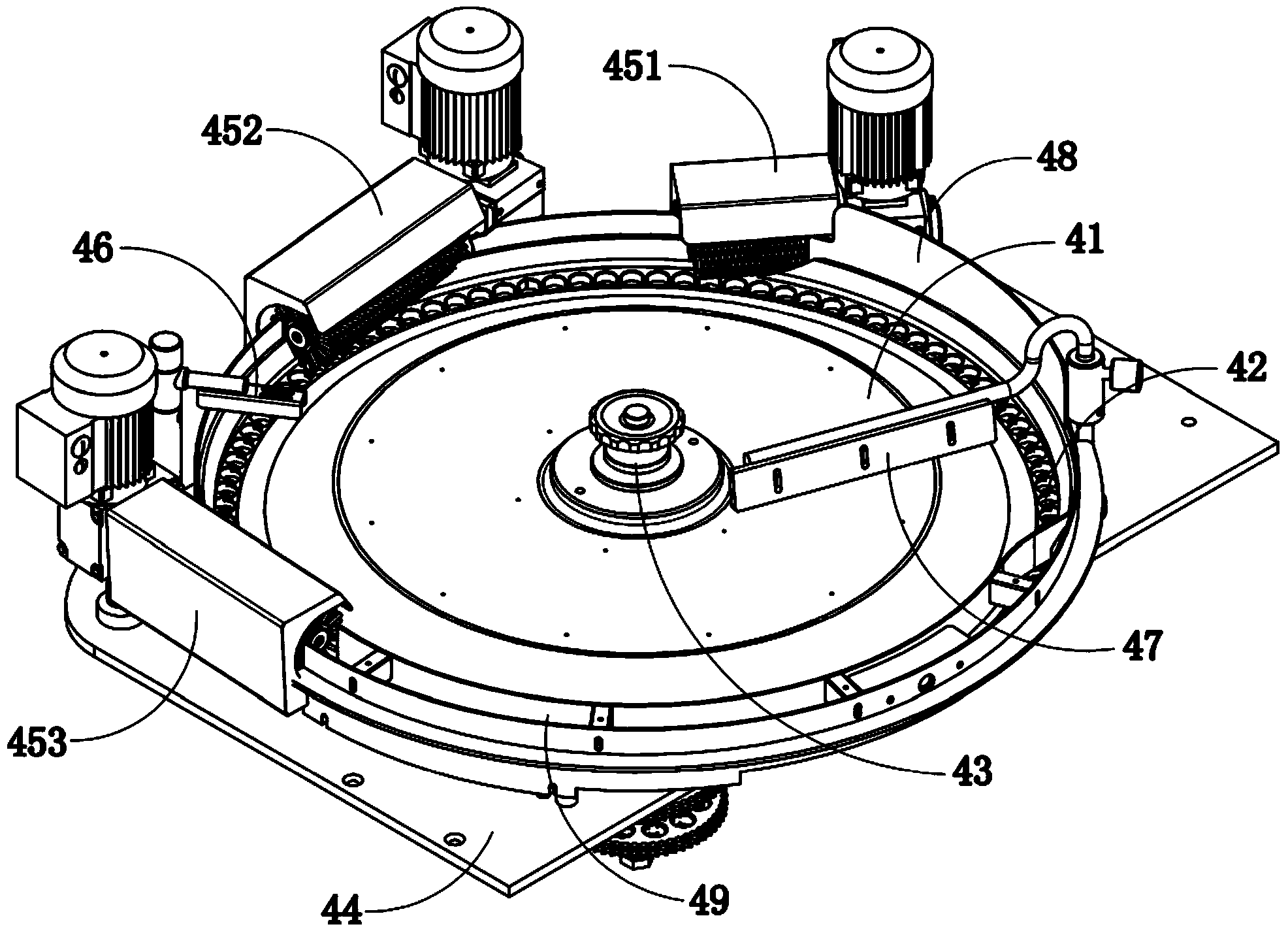

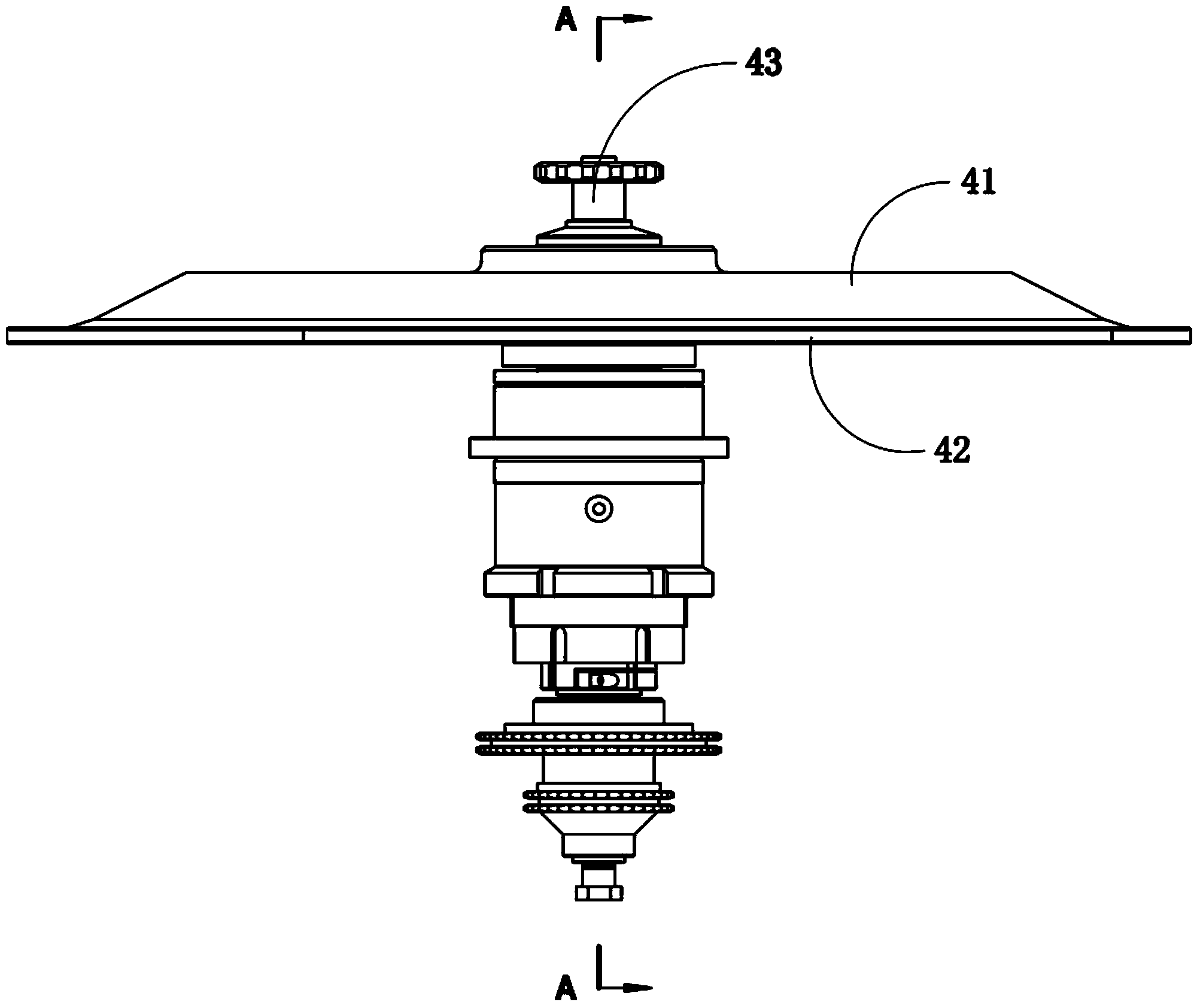

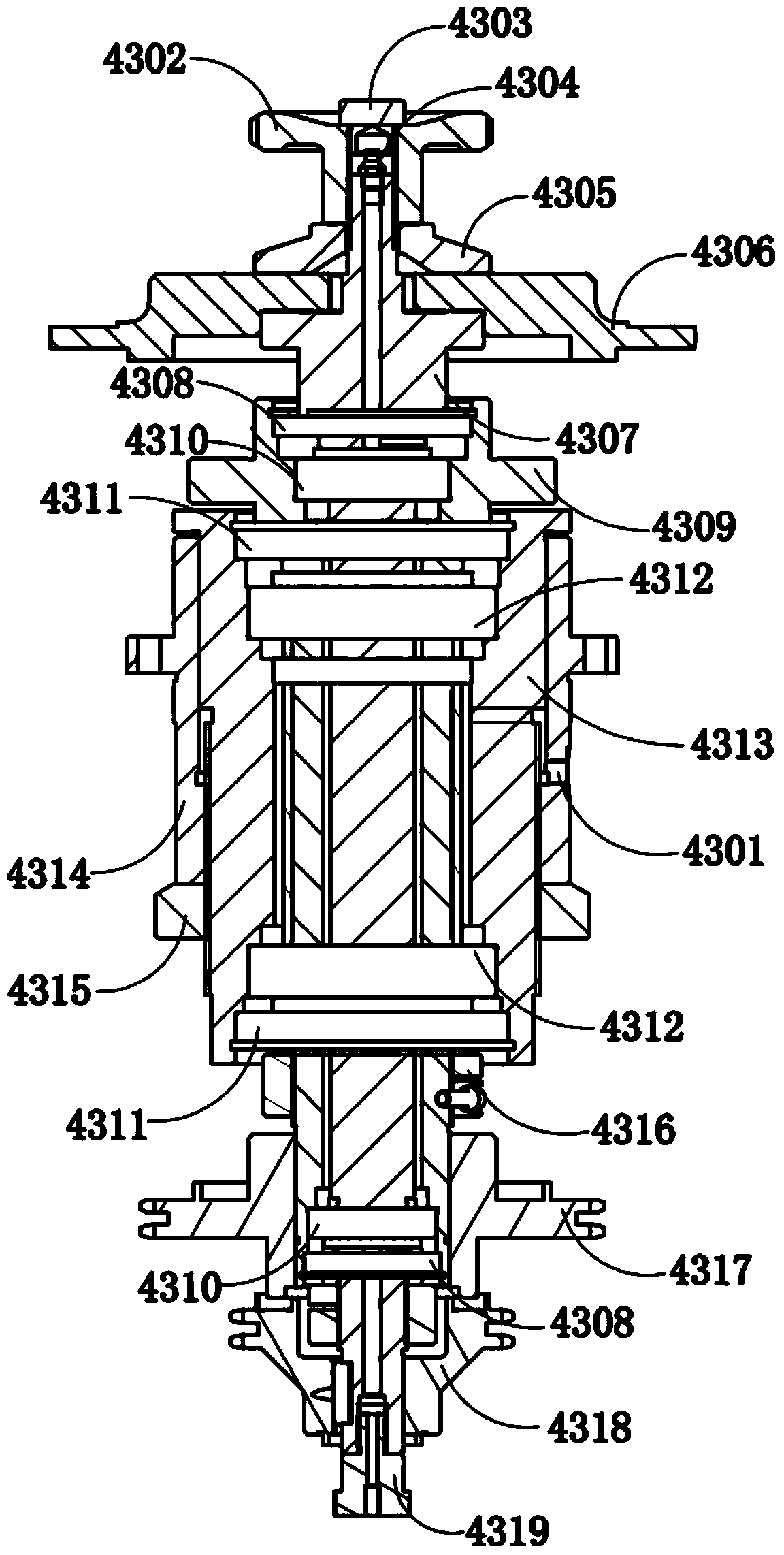

[0034] like Figure 1 to Figure 7As shown, the sugar sorting device in this embodiment includes a sugar throwing assembly 41, a counting plate assembly 42, a drive shaft assembly 43, a sugar holding plate 44, a sugar brushing assembly, a sugar amount detection switch 46, a sugar blocking plate 47, and an outer gear. Plate 48 and sugar falling track 49; sugar throwing assembly 41, counting plate assembly 42 and sugar holding plate 44 are sleeved on drive shaft assembly 43 from top to bottom in sequence, and sugar throwing assembly 41 and counting plate assembly 42 are all circular , the diameter of the counting plate assembly 42 is greater than the diameter of the sugar throwing assembly 41; the outer baffle plate 48 is fixed around the periphery of the counting plate assembly 42 to prevent the candy from falling from the rotating counting plate assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com