Transport device for concave part

A technology of transmission device and transmission device, which is applied in the direction of transportation and packaging, conveyor objects, etc., and can solve problems such as high error rate and waste of labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

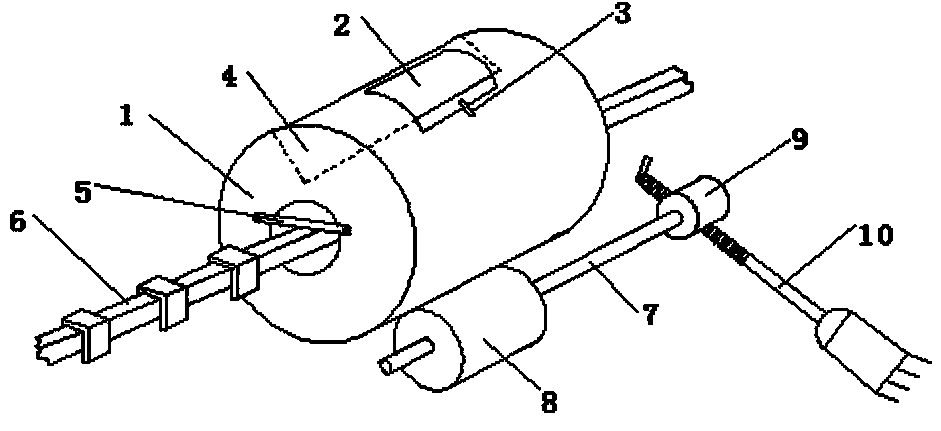

[0012] The drawings in the description of the drawings are: storage tank 1; opening and closing door 2; locking device 3; partition 4; error correction rod 5;

[0013] Such as figure 1 As shown, the technical solution provides a transmission device for concave parts, including a storage device, a transmission device and a transmission device. The material storage device includes a material storage cylinder 1, which is horizontally arranged on the bracket along its axial direction, and a feed inlet is opened above it, and an opening and closing door 2 for closing the feed inlet is hinged at one end of the feed inlet. , the free end of the opening and closing door 2 is equipped with a locking device 3 for locking with the storage barrel 1, and the locking device 3 includes a latch installed on the opening and closing door 2 and a locking device installed on the storage barrel 1 jack. When feeding is required, withdraw the latch on the opening and closing door 2 from the socket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com