Preparation method for upconversion graphene oxide and application in indicating pH of water sample

A graphene and graphene solution technology, applied in chemical instruments and methods, measuring devices, material analysis through optical means, etc., to achieve the effects of small size, high yield, and good water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

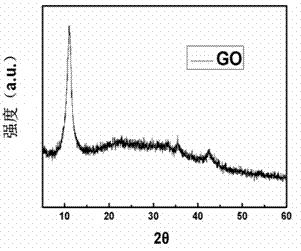

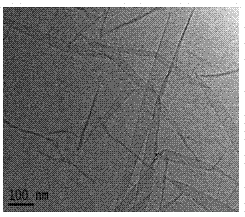

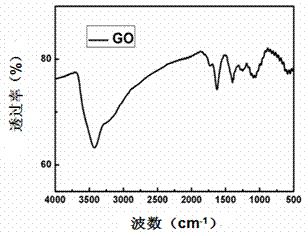

[0029] (1) Pre-oxidation process of graphite: add 1.5 g of graphite flakes into a 250 mL three-neck flask, then add 6 mL of concentrated sulfuric acid, 1.2 g of Na 2 S 2 o 8 and 1.25 g P 2 o 5 , stirred at 80°C for 4.5 h, cooled to room temperature, added 250 mL of high-purity water, and left overnight. Centrifuge to neutral, dry in vacuum at 35°C to obtain solid pre-oxidized graphite;

[0030] (2) Preparation of graphene oxide: Add 20 mL of concentrated sulfuric acid to a three-neck flask containing 0.5 g of pre-oxidized graphite flakes at 0 °C, and slowly add 2.5 g of KMnO 4 , raised the temperature to 35°C, stirred for 4 h, then slowly added 45 mL of high-purity water and stirred for another 2 h, then added 120 mL of high-purity water and 4 mL of H 2 o 2 , washed with 1 L of 1:10 HCl, centrifuged, then washed with high-purity water, centrifuged to neutral, and the obtained solution was ultrasonicated to form a graphene oxide solution for subsequent use;

[0031] (3) ...

Embodiment 2

[0035] (1) Pre-oxidation process of graphite: add 1.5 g of graphite flakes into a 250 mL three-neck flask, then add 6 mL of concentrated sulfuric acid, 1.2 g of Na 2 S 2 o 8 and 1.25 g P 2 o 5 , stirred at 50°C for 4.5 h, cooled to room temperature, added 250 mL of high-purity water, and left overnight. Centrifuge to neutral, dry in vacuum at 35°C to obtain solid pre-oxidized graphite;

[0036] (2) Preparation of graphene oxide: Add 12 mL of concentrated sulfuric acid to a three-neck flask containing 0.5 g of pre-oxidized graphite flakes at 0 °C, and slowly add 2.5 g of KMnO 4 , raised the temperature to 35°C, stirred for 2 h, then slowly added 45 mL of high-purity water and stirred for another 2 h, then added 120 mL of high-purity water and 4 mL of H 2 o 2 , washed with 1L of 1:10 HCl, centrifuged, then washed with high-purity water, centrifuged to neutral, and the obtained solution was ultrasonicated to form a graphene oxide solution for subsequent use;

[0037] (3) T...

Embodiment 3

[0041] A preparation method of graphene oxide with up-conversion properties, characterized in that it proceeds in the following steps:

[0042] (1) The pre-oxidation process of graphite: add 1.5 g of graphite flakes into the three-neck flask, then add 6 mL of concentrated sulfuric acid, 1.2 g of Na 2 S 2 o 8 and 1.25 g P 2 o 5 , stirred at 65°C for 4.5 h, cooled to room temperature, added 250 mL of high-purity water, and stood overnight; centrifuged to neutral, and dried under vacuum at 35°C to obtain solid pre-oxidized graphite;

[0043] (2) Preparation of graphene oxide: Add 16 mL of concentrated sulfuric acid to a three-neck flask containing 0.5 g of pre-oxidized graphite flakes at 0 °C, and slowly add 2.5 g of KMnO 4 , raised the temperature to 35°C, stirred for 3 h, then slowly added 45 mL of high-purity water and stirred for another 2 h, then added 120 mL of high-purity water and 4 mL of H 2 o 2 , washed with 1 L of 1:10 HCl, centrifuged, washed with high-purity wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com