Insulating wax composition and its preparation method and transformer

A technology of wax composition and transformer, applied in transformer/inductor casing, chemical instrument and method, other chemical processes, etc., can solve the problems of easy loss, high temperature performance, poor toughness and plasticity, easy cracking, etc., and the method steps are simple , excellent insulation, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The present invention also provides a preparation method of an insulating wax composition, the preparation method comprising: mixing rice bran wax, candelilla wax, montan wax, thickener, petrolatum, nano-mica powder and polyacrylic acid, heating and stirring ;

[0019] Wherein, relative to 100 parts by weight of rice bran wax, the consumption of the candelilla wax is 30-45 parts by weight, the consumption of the montan wax is 20-35 parts by weight, and the consumption of the thickener is 7-45 parts by weight. 13 parts by weight, the consumption of the petrolatum is 8-15 parts by weight, the consumption of the nano mica powder is 12-16 parts by weight, the consumption of the polyacrylic acid is 5-7 parts by weight; the thickener is selected from One or more of methylcellulose, hydroxypropylmethylcellulose and hydroxyethylcellulose.

[0020] In the present invention, the particle size of the nano-mica powder can be selected in a wide range, as long as it reaches the nano...

Embodiment 1

[0030] Mix 100g of rice bran wax, 35g of candelilla wax, 25g of montan wax, 10g of methylcellulose, 11g of petrolatum, 14g of nano-mica powder and 6g of polyacrylic acid at 25°C for 20min, then heat and stir at 120°C for 2.5h. Insulating wax composition A1 was obtained. Wherein, the particle size of the nano mica powder is 8nm, the weight average molecular weight of the polyacrylic acid is 2500, the melting point of the rice bran wax is 80°C, and the dropping point of the vaseline is 55°C.

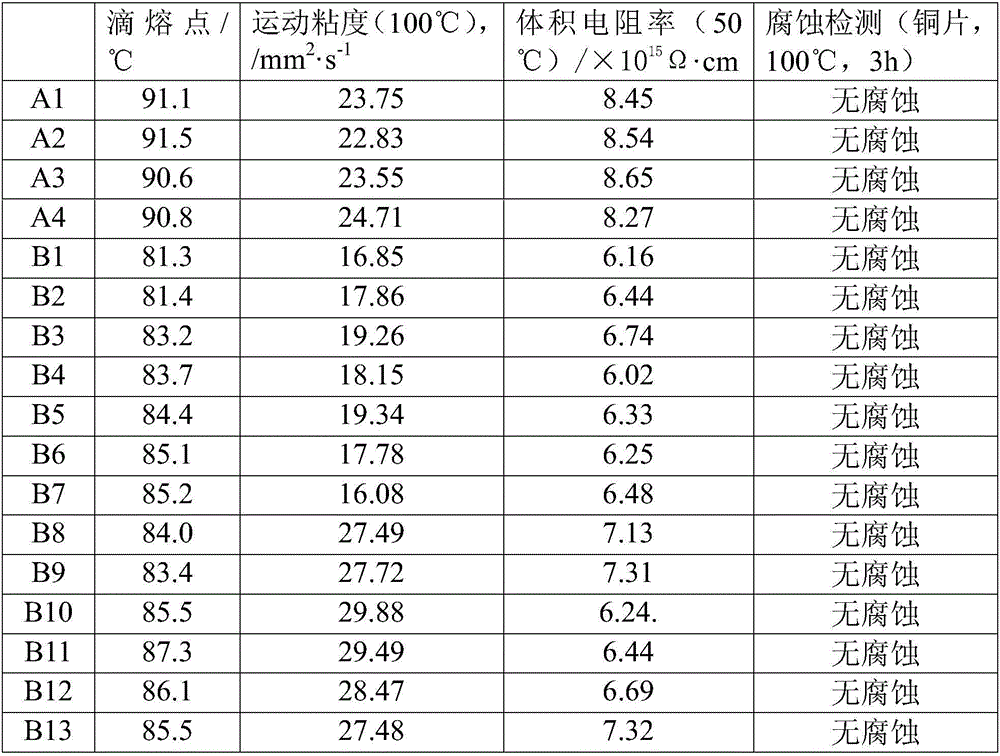

[0031] The dropping melting point, kinematic viscosity, volume resistivity and corrosion detection results of the insulating wax composition are shown in Table 1.

Embodiment 2

[0033] Mix 100g of rice bran wax, 30g of candelilla wax, 20g of montan wax, 7g of methylcellulose, 8g of petrolatum, 12g of nano-mica powder and 5g of polyacrylic acid at 20°C for 15min, then heat and stir at 115°C for 2h. Insulating wax composition A2. Wherein, the particle size of the nano mica powder is 5nm, the weight average molecular weight of the polyacrylic acid is 2000, the melting point of the rice bran wax is 77°C, and the dropping point of the vaseline is 45°C.

[0034] The dropping melting point, kinematic viscosity, volume resistivity and corrosion detection results of the insulating wax composition are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com