A high temperature resistant and anti-corrosion transformer

A high-frequency transformer and transformer technology, applied in the field of electronic transformers and high-frequency transformers, can solve problems such as unusable performance, achieve excellent electrical insulation performance, excellent high-temperature performance, and ensure electrical performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

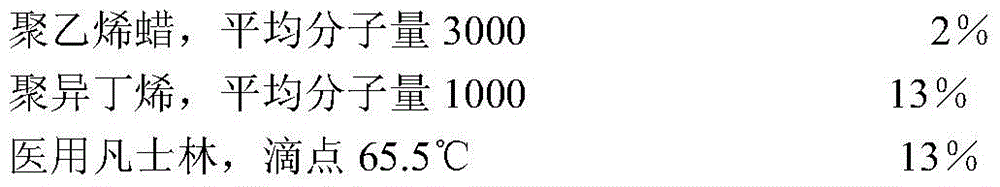

[0030] Embodiment: (below all represent by weight percentage)

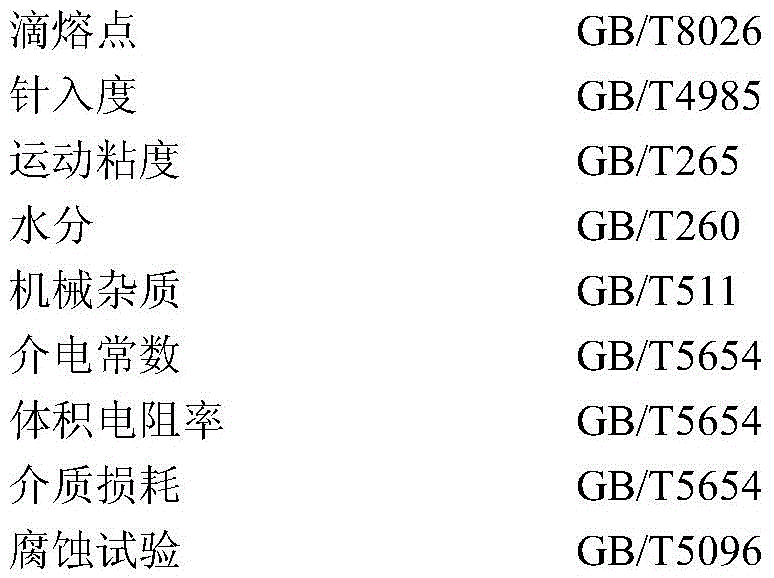

[0031] experiment method

[0032] The following test methods are the usual ones for testing waxes used in the electronics industry used in the examples.

[0033]

[0034] The insulating potting waxes of Examples 1 to 4 and Comparative Examples 1 to 5 of the present invention are prepared by adding raw materials sequentially at a temperature of about 110°C to 140°C and mixing and melting to form a uniform and transparent wax liquid, which is filtered and then cooled. forming.

Embodiment 1(E1

[0036]

[0037]

Embodiment 2(E2

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com