A kind of insulating potting wax composition

A composition and technology for potting wax, applied in the field of insulating potting wax compositions for electronic transformers and high-frequency transformers, can solve problems such as unusable performance, and achieve excellent electrical insulation performance, extended service life, moisture resistance and resistance. good corrosive effect

Inactive Publication Date: 2016-10-05

JINGMEN WEIJIA CHEM

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Invention patent CN1458216A discloses a sealing wax for electronic components, including petroleum wax, polymer wax, tackifier and plasticizer, mainly used for positioning and sealing of electronic tuners, inductor coils and other electronic component coils. However, for electronic transformers and high-frequency transformers with high requirements for liquid fluidity and dielectric loss, insulation impregnation and potting cannot make them have the best performance.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0030] Embodiment: (below all represent by weight percentage)

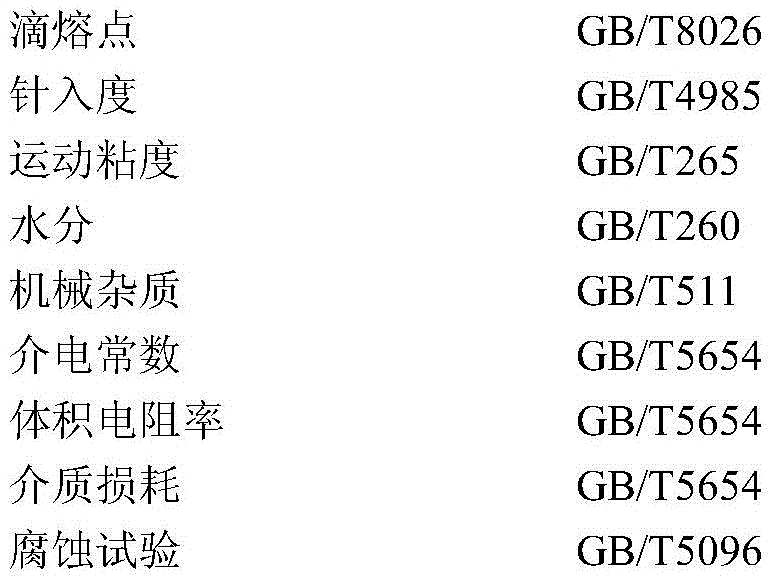

[0031] experiment method

[0032] The following test methods are the usual ones for testing waxes used in the electronics industry used in the examples.

[0033]

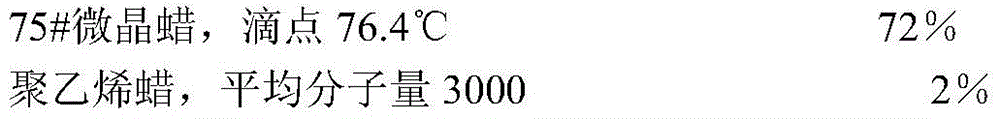

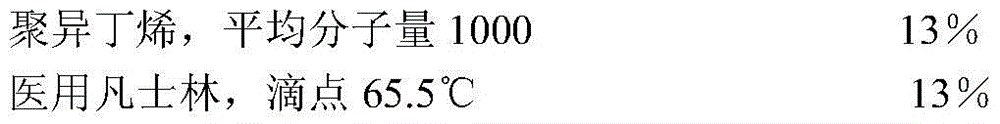

Embodiment 1

[0035] Example 1 (E1)

[0036]

[0037]

Embodiment 2

[0040] Example 2 (E2)

[0041]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to an insulating potting wax composition, comprising 72%-78% of petroleum wax, 2%-4% of polyethylene wax, 9%-13% of tackifier, and 9%-13% of vaseline . The high-temperature-resistant and anti-corrosion transformer of the present invention has the characteristics of excellent high-temperature performance and anti-corrosion performance, excellent electrical performance, good moisture resistance, and the like. The insulating potting wax composition is not only suitable for insulating impregnation potting of electronic transformers and high-frequency transformers, but also suitable for insulating dipping potting of inductance coils and other special coils of electronic components.

Description

technical field [0001] The invention relates to an insulating potting wax composition, in particular to an insulating potting wax composition used for electronic transformers and high-frequency transformers. Background technique [0002] In the production of transformers, it is often necessary to use insulating potting wax to impregnate and pot the transformer to improve the insulation performance of the transformer. In the prior art, commercial paraffin or microcrystalline wax is simply used. Although the price is cheap, there are defects such as poor high-temperature performance and toughness and plasticity. Potting transformers with oil is prone to leakage. The use of resin materials can make the transformer have good high temperature resistance, but it has defects such as poor toughness and plasticity and high production cost, which cannot meet the requirements of current manufacturers. [0003] In the prior art, for example, a waxy composition is disclosed in the inve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L91/06C08L23/06C08L23/20

Inventor 江志鑫

Owner JINGMEN WEIJIA CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com