Preparation method of casting medium-temperature model wax

A model, medium temperature technology, applied in the field of casting materials, can solve the problems affecting the dimensional accuracy and quality of precision castings, and achieve the effects of good fluidity and molding, good surface finish, and high dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

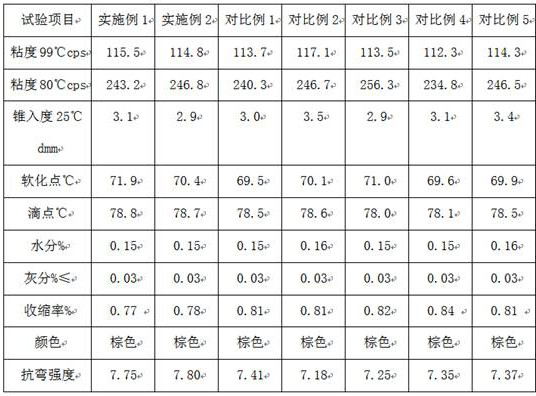

Examples

Embodiment 1

[0022] (1) In parts by weight, weigh the following raw materials and set aside: morpholine fatty acid salt fruit wax 1.5, ethylene bisoleic acid amide 6, polyamide wax 15, glycerol trihydroxystearate 7, erucamide 21 , montan wax 2.5, stearic acid soap 7, polychlorotrifluoroethylene wax 4, low molecular weight AMS resin 1, oleic acid amide 4, silicone powder 0.2, trans-1,4-polyisoprene 19, add Additive 12; (2) Mix the weighed morpholine fatty acid salt fruit wax, ethylene bisoleic acid amide, and polyamide wax, grind them, add glycerol trihydroxystearate, trans-1,4- Stir the polyisoprene evenly, granulate, and the particle size is 0.05mm to obtain colloidal particles; (3) Mix the weighed erucamide, montan wax, low molecular weight AMS resin, stearic acid soap, polytrifluoroethylene Vinyl chloride wax, oleic acid amide, and silicone powder were ground for 15 minutes to obtain a mixed material; (4) the colloidal particles and the mixed material obtained in step (3) were mixed and...

Embodiment 2

[0025] (1) In parts by weight, weigh the following raw materials and set aside: Morpholine fatty acid salt fruit wax 1.3, ethylene bisoleic acid amide 4, polyamide wax 13, glycerol trihydroxystearate 5, erucamide 18 , montan wax 2, stearic acid soap 5, polychlorotrifluoroethylene wax 2, low molecular weight AMS resin 0.7, oleic acid amide 2, silicone powder 0.1, trans-1,4-polyisoprene 17, add Additive 11; (2) Mix the weighed morpholine fatty acid salt fruit wax, ethylene bisoleic acid amide, and polyamide wax, grind them, add glycerol trihydroxystearate, trans-1,4- Stir the polyisoprene evenly, granulate, and the particle size is 0.05mm to obtain colloidal particles; (3) Mix the weighed erucamide, montan wax, low molecular weight AMS resin, stearic acid soap, polytrifluoroethylene Vinyl chloride wax, oleic acid amide, and silicone powder were ground for 10 minutes to obtain a mixed material; (4) the colloidal particles and the mixed material obtained in step (3) were mixed and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com