Full-glass double-skin curtain wall system

An all-glass and curtain wall technology, applied to walls, building components, buildings, etc., can solve problems such as high heat transfer coefficient, large gap, and reduced heat transfer coefficient, so as to improve thermal insulation performance, facilitate installation, improve safety and stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

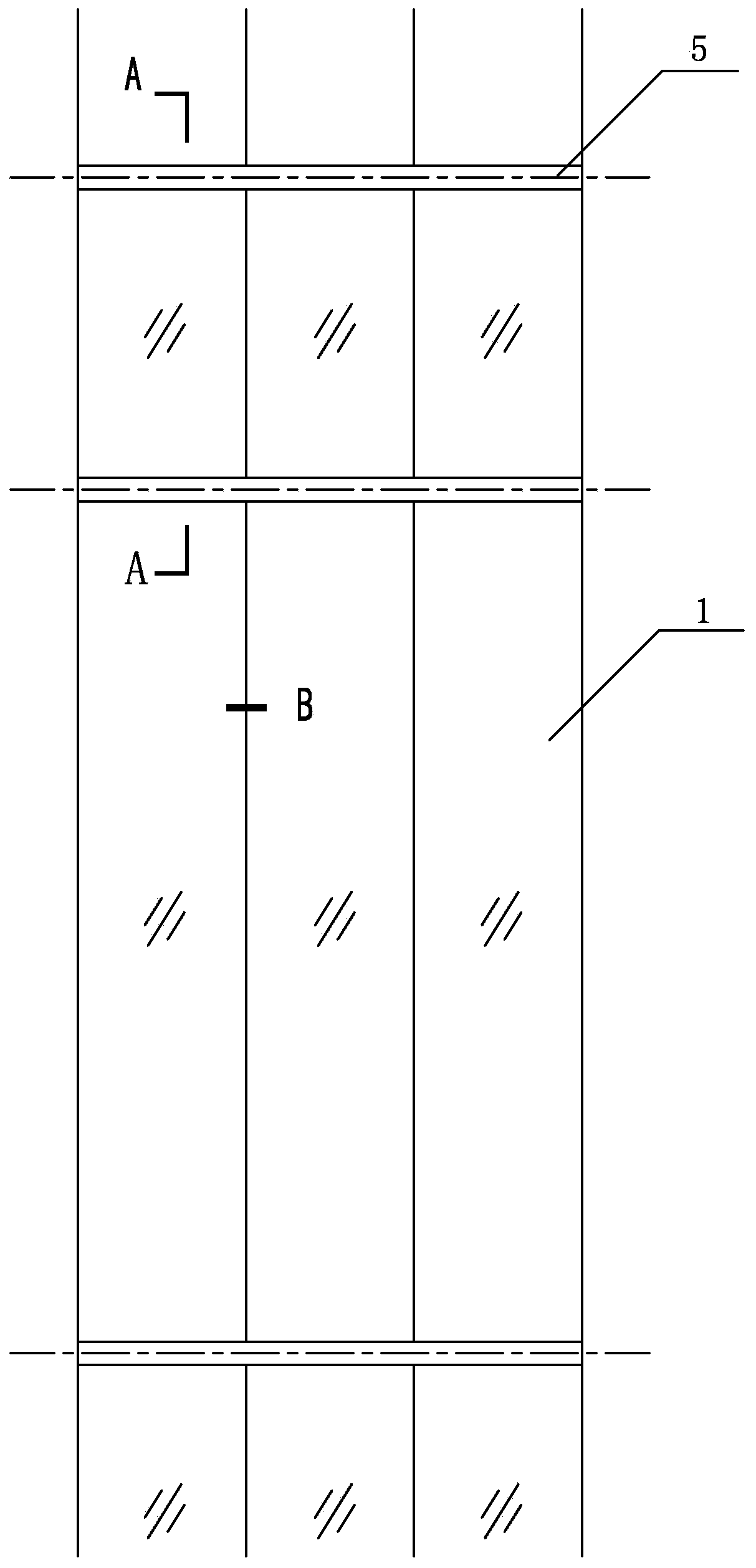

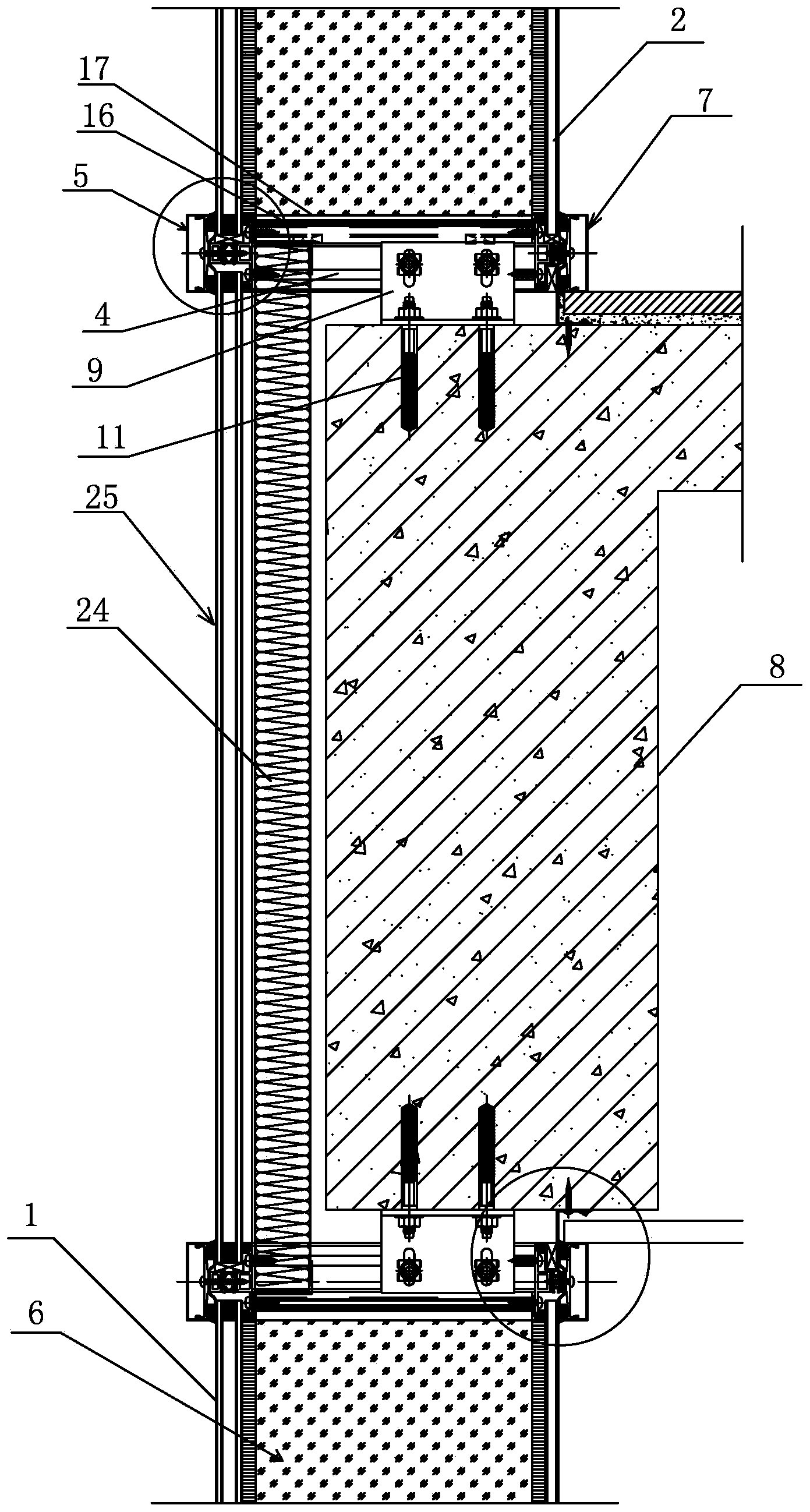

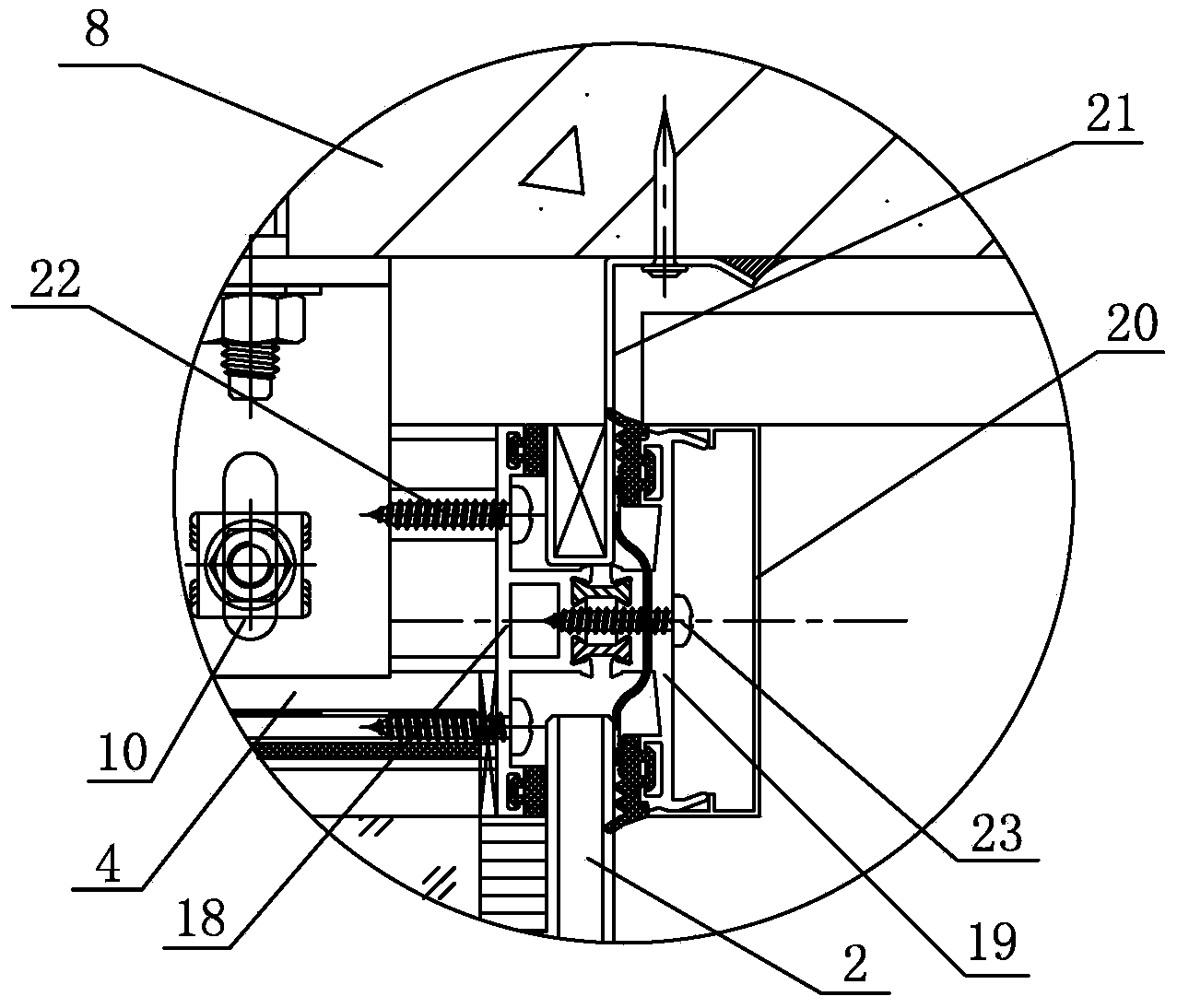

[0035] Embodiment one: see Figure 1-7 As shown, an all-glass double-layer curtain wall system includes a glass panel 1, an inner glass panel 2, an inner beam 7, a glass rib 3, and a glass rib support 4, and a transitional curtain wall is set at the floor between the upper and lower floors 25. The transitional curtain wall 25 includes a transitional glass panel 26 and a beam 5 connecting the upper and lower glass panels 1. The beam 5 is located on the upper and lower sides of the floor 8. The glass rib support 4 is supported by an angle steel The seat 9 and the bolt assembly are fixed to the floor 8; the beam 5 includes an outer beam support 27, a cover plate 28 and an outer decorative cover plate 29, and the outer beam support 27 is fixed to the glass rib support by screws 30 On the seat 4, the cover plate 28 is connected to the outer beam support 27 through connecting screws 31, the transition glass panel 26 on one side and the glass panel 1 on the other side are arranged on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com