Fiber/powder composite felt and preparation method thereof and vacuum thermal insulation panel

A technology of fiber felt and composite felt, applied in the field of thermal insulation materials, which can solve the problems of high strength, small aperture, and high rebound rate of the core material of vacuum insulation panels, and achieve small expansion rate, reduced rebound rate and pore diameter, and good embryo body The effect of suppressing mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

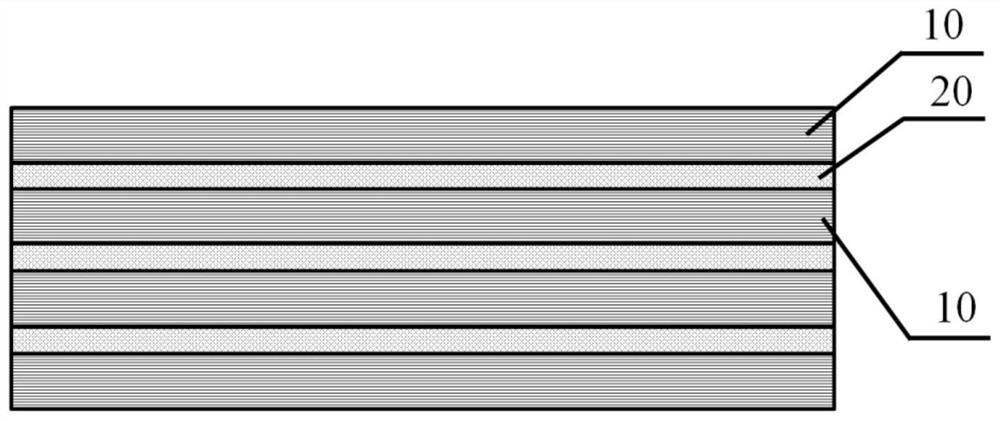

[0034] (1) Cut and weigh 15 pieces of centrifugal cotton felt of 300*300*0.5mm, stack 5 pieces of them together, and put them into a metal mold;

[0035] (2) Evenly mix 45 parts of fumed silica, 45 parts of precipitated silica and 10 parts of silicon micropowder in a mixer, weigh 15 pieces of mixed powder of centrifugal cotton felt weight 1 / 20, and spread it evenly Form a powder layer on the surface of the centrifugal cotton felt;

[0036] (3) Superimpose 5 centrifugal cotton felts of 300*300*0.5mm on the surface of the powder layer;

[0037] (4) Evenly spread 15 pieces of mixed powder of 1 / 20 weight of centrifugal cotton felt on the surface of centrifugal cotton felt to form the second powder layer, and then superimpose 5 pieces of centrifugal cotton of 300*300*0.5mm on the surface Felt, using a press to heat-press the fiber felt and powder layer, the hot-pressing temperature is 450°C, the pressure is 8MPa, and the time is 12min, so as to form a pressed blank;

[0038] (5) ...

Embodiment 2

[0041] (1) Cut 20 pieces of 300*300*0.5mm centrifugal / flame cotton felt (70% centrifugal cotton + 30% flame cotton) and weigh them, stack 5 of them together and put them into a metal mold;

[0042] (2) 50 parts of fumed silica, 40 parts of precipitated silica and 10 parts of low-melting nylon fibers are uniformly mixed in a blender, from which 20 pieces of mixed powder of centrifugal / flame cotton felt weight 1 / 30 are weighed, and Spread it evenly on the surface of the centrifugal / flame cotton felt to form a powder layer;

[0043](3) Superimpose 5 centrifugal / flame cotton felts of 300*300*0.5mm on the surface of the powder layer;

[0044] (4) Repeat step (2) and step (3) 3 times, use press to carry out hot pressing treatment to fiber felt and powder layer, described hot pressing temperature is 180 ℃, pressure is 5MPa, time is 2min, makes it form pressed blanks;

[0045] (5) Demoulding the pressed blank, ejecting it and pushing it out of the machine to form a fiber / powder comp...

Embodiment 3

[0048] (1) Cut and weigh 50 glass fiber chopped strands / low-melting point polyester fiber mats (90% glass fiber chopped strands + 10% low-melting point polyester fibers) of 200*200*0.3mm, and weigh 10 of them The sheets are stacked together and placed in metal molds;

[0049] (2) Mix 50 parts of fumed silica, 44 parts of precipitated silica and 6 parts of low melting point glass powder in a mixer, and weigh 50 pieces of glass fiber chopped strands / low melting point polyester fiber mat weight 1 / 60 mixed powder, and spread it evenly on the surface of glass fiber chopped strands / low melting point polyester fiber mat to form a powder layer;

[0050] (3) Superimpose 10 glass fiber chopped strands / low-melting point polyester fiber mats of 200*200*0.3mm on the surface of the powder layer;

[0051] (4) Repeat step (2) and step (3) 4 times, and use a press to perform hot pressing treatment on the fiber felt and powder layer. The hot pressing temperature is 260 ° C, the pressure is 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com