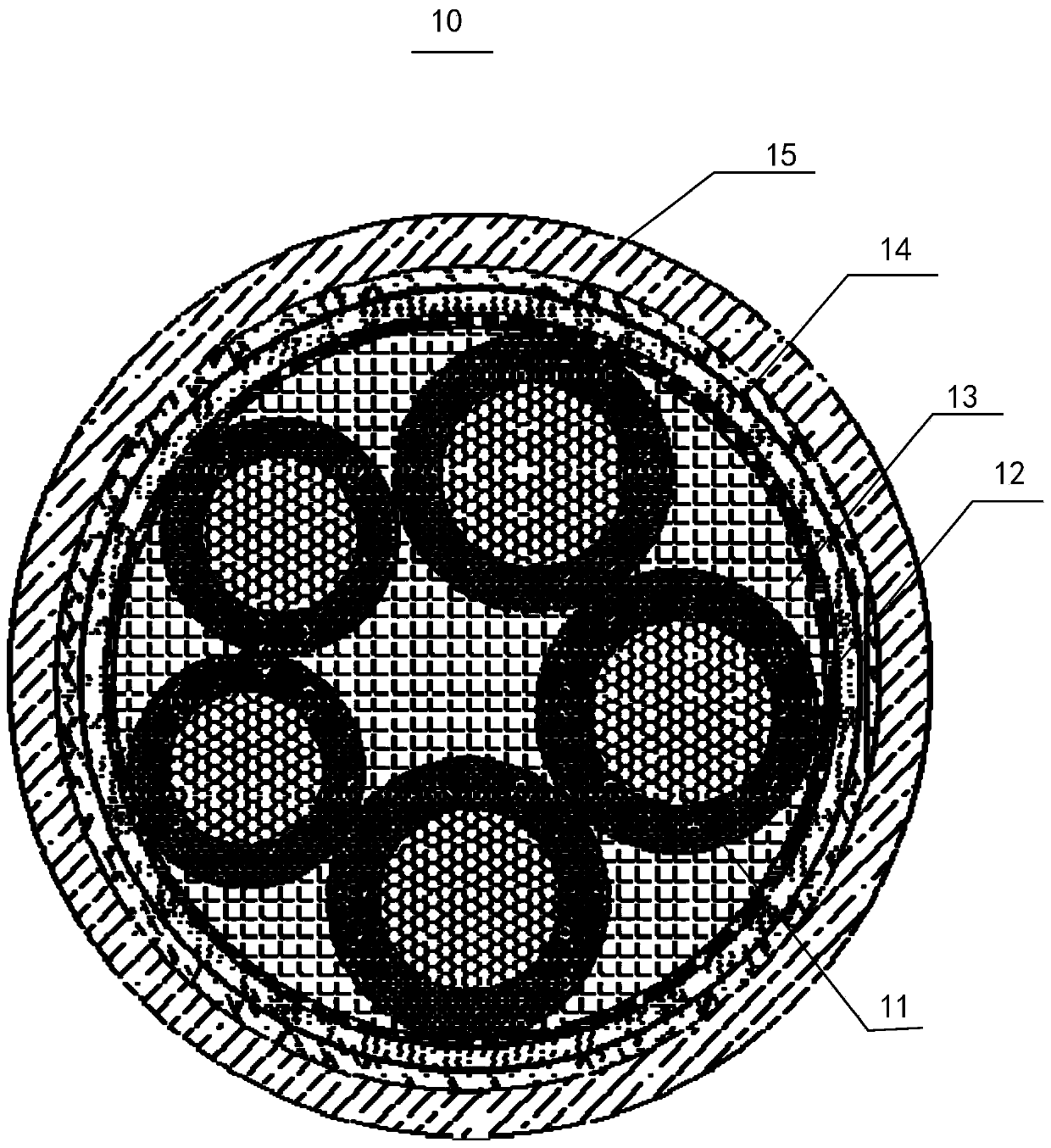

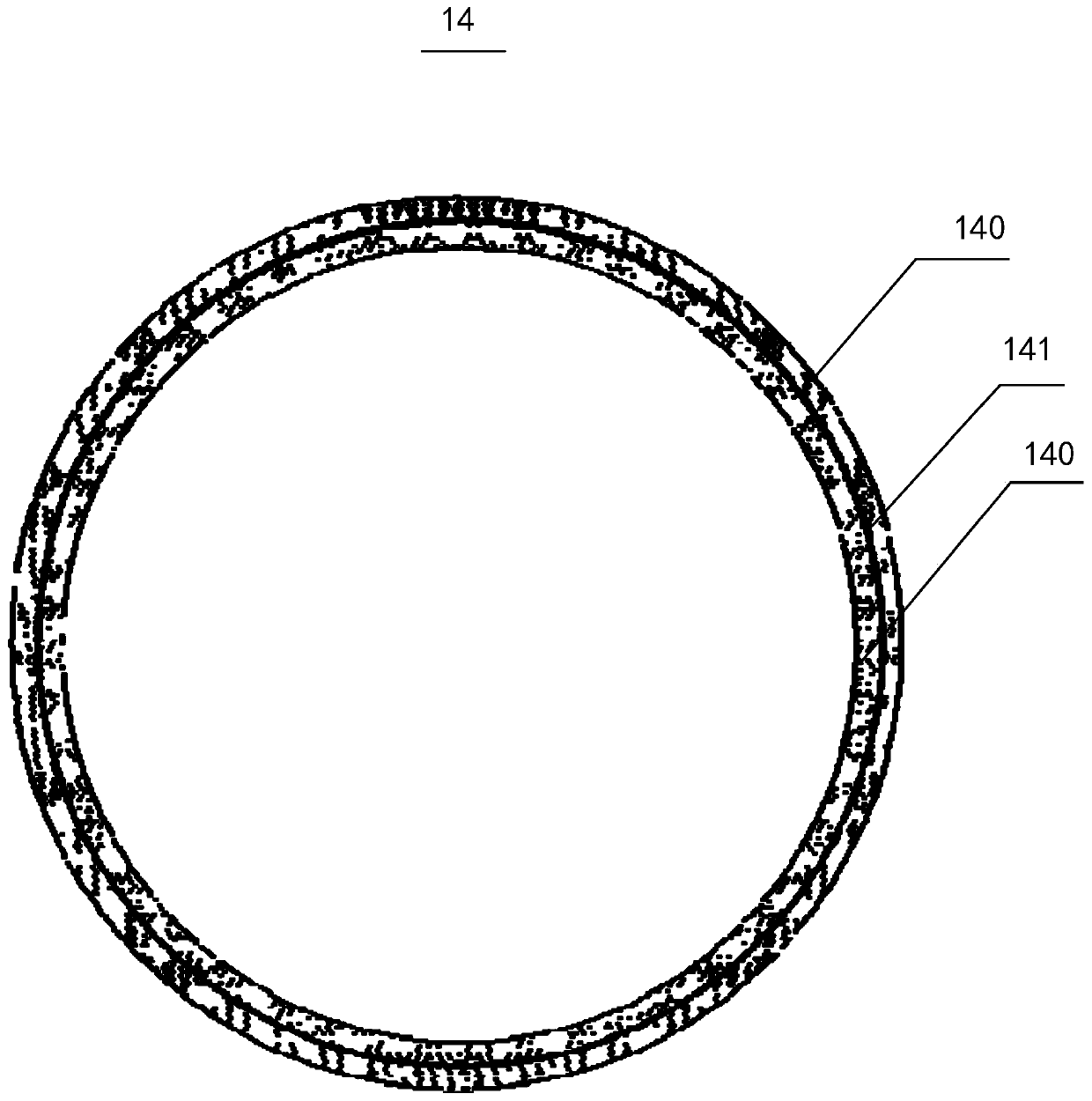

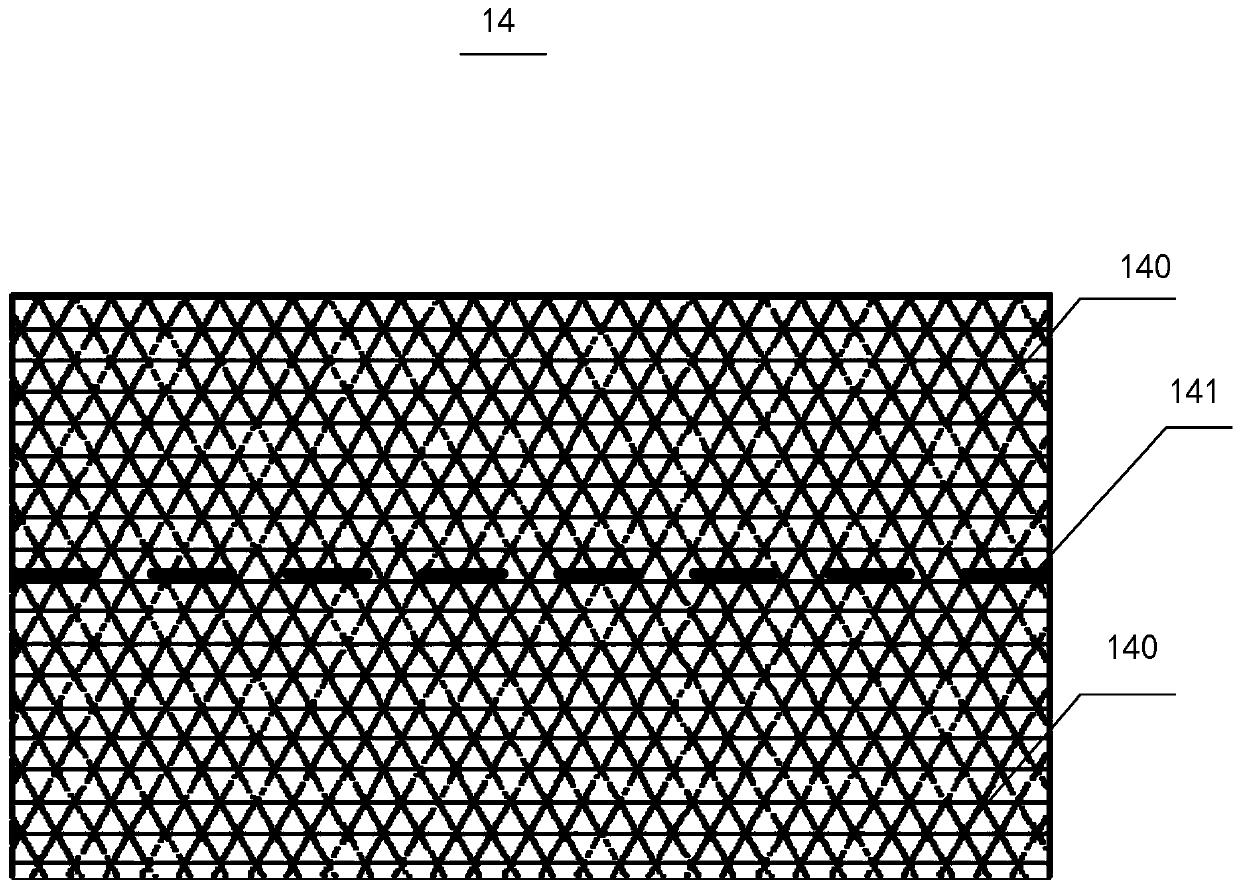

A fiber reinforced fireproof cable

A fire-resistant cable, reinforced technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor bending performance, cracks in the fire insulation layer, and inability to produce large lengths, and achieve improved thermal resistance and mechanical properties. Tensile strength and mechanical impact, ensuring safety and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The inventor found that under fire conditions, the application environment of fireproof cables is very complex and harsh, not only the high temperature caused by flame burning, but also the collision, extrusion and impact caused by the collapse of other objects at the fire scene, as well as fire protection. Such harsh environmental conditions will seriously affect the fire-resistant reliability of fire-resistant cables, thereby threatening the safety and durability of fire-fighting system operation. In addition, during a fire, although the fireproof cable can withstand flame ablation and maintain the integrity of the line with a certain amount of mechanical impact and spraying, the internal core temperature of the fireproof cable is mostly in the case of flame ablation. It will rise, and the increase of pressure drop will affect the current carrying capacity of the cable. In addition, since the fire-resistant cables used in various engineering projects are mostly small-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com