Aluminum-wood combined suit door and installation method thereof

A technology of aluminum-wood and sleeve doors, which is applied to door leaves, windows/doors, building components, etc., can solve the problems of unfilled market space, reduced use time, and high relative water content, so as to improve service life, save costs, and improve structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

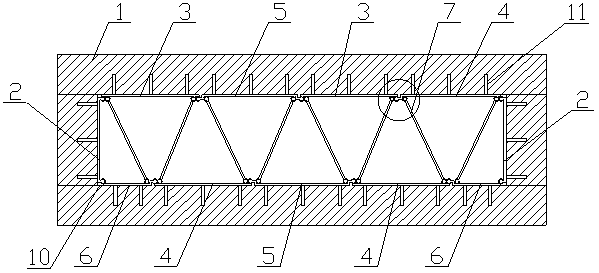

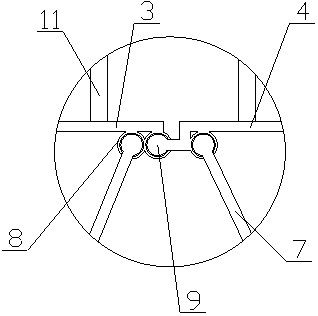

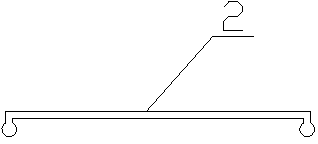

Embodiment 1

[0038] Such as Figure 1 to Figure 11 As shown, an aluminum-wood combination door of the present invention includes a door leaf and a door frame. The door leaf includes a door frame composed of multiple aluminum plates and a solid wood door panel 1 wrapped on the surface of the door frame. The door frame and the solid wood door panel 1 are nailed Or self-working nails 10 are installed and fixed. The narrow side of the door frame is an aluminum edge banding plate 2, and the long side of the door frame is composed of an aluminum substrate one 3, an aluminum substrate two 4, an aluminum substrate three 5 and an aluminum substrate The base plate is composed of 4 and 6. The narrow side and long side of the door frame are connected together through the connecting groove 8 and the connecting protrusion 9 at the end of the aluminum plate. There are multiple aluminum hollow connecting plates 7 inside the door frame. The two ends of the aluminum hollow connecting plate 7 are connected t...

Embodiment 2

[0045] Such as figure 1 As shown, the present invention is as Figure 1 to Figure 11As shown, an aluminum-wood combination door of the present invention includes a door leaf and a door frame. The door leaf includes a door frame composed of multiple aluminum plates and a solid wood door panel 1 wrapped on the surface of the door frame. The door frame and the solid wood door panel 1 are nailed Or self-working nails 10 are installed and fixed. The narrow side of the door frame is an aluminum edge banding plate 2, and the long side of the door frame is composed of an aluminum substrate one 3, an aluminum substrate two 4, an aluminum substrate three 5 and an aluminum substrate The base plate is composed of 4 and 6. The narrow side and long side of the door frame are connected together through the connecting groove 8 and the connecting protrusion 9 at the end of the aluminum plate. There are multiple aluminum hollow connecting plates 7 inside the door frame. The two ends of the alu...

Embodiment 3

[0052] Such as figure 1 As shown, the present invention is as Figure 1 to Figure 11 As shown, an aluminum-wood combination door of the present invention includes a door leaf and a door frame. The door leaf includes a door frame composed of multiple aluminum plates and a solid wood door panel 1 wrapped on the surface of the door frame. The door frame and the solid wood door panel 1 are nailed Or self-working nails 10 are installed and fixed. The narrow side of the door frame is an aluminum edge banding plate 2, and the long side of the door frame is composed of an aluminum substrate one 3, an aluminum substrate two 4, an aluminum substrate three 5 and an aluminum substrate The base plate is composed of 4 and 6. The narrow side and long side of the door frame are connected together through the connecting groove 8 and the connecting protrusion 9 at the end of the aluminum plate. There are multiple aluminum hollow connecting plates 7 inside the door frame. The two ends of the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com