Drive belt tensioning device and tensioning method

A technology for transmission belts and tensioning devices, which is applied in the direction of transmissions, belts/chains/gears, mechanical equipment, etc. It can solve problems such as tensioning failure, thread bite failure, slipping, etc., to improve anti-interference ability and transmit torque The effect of enhanced ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

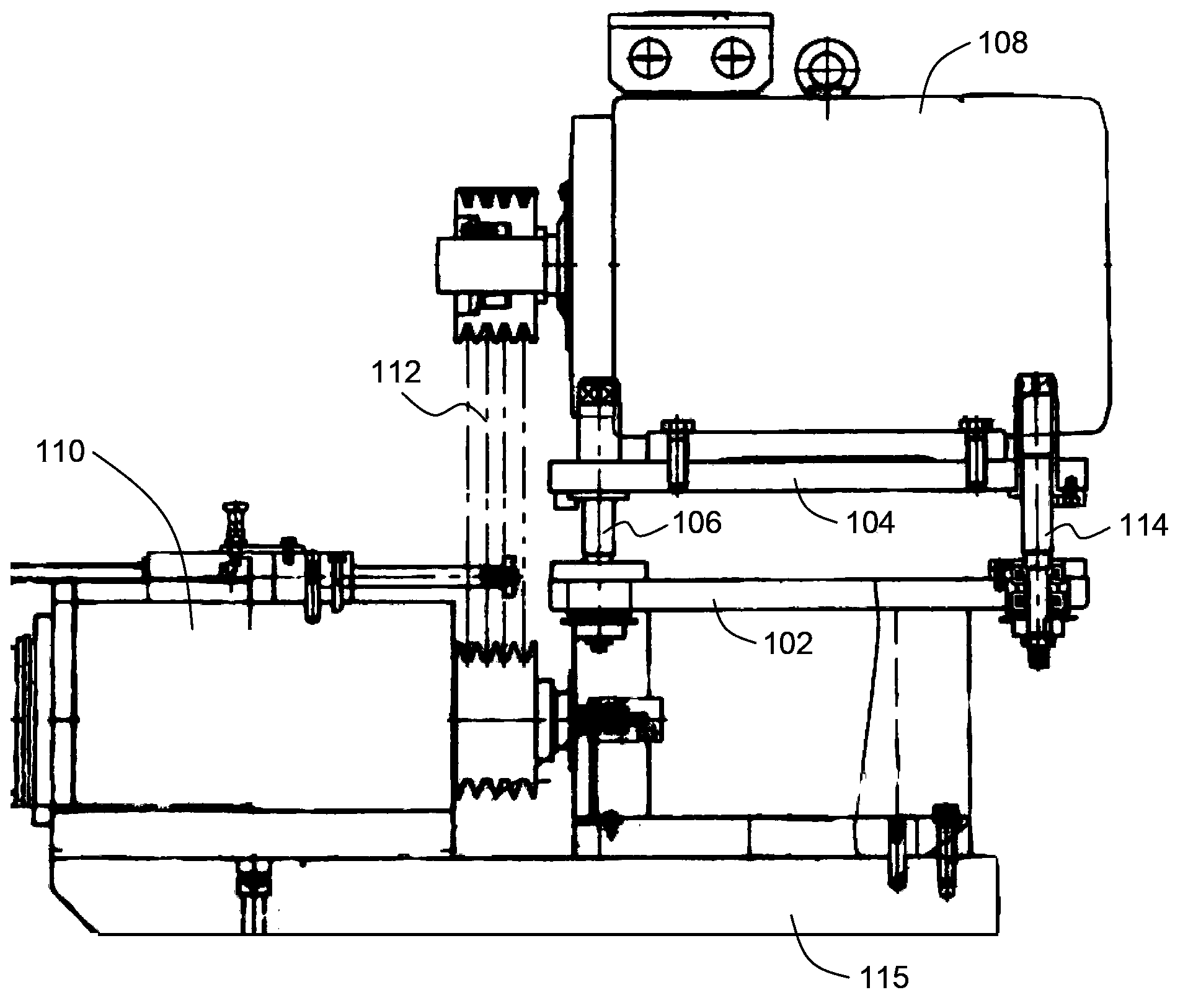

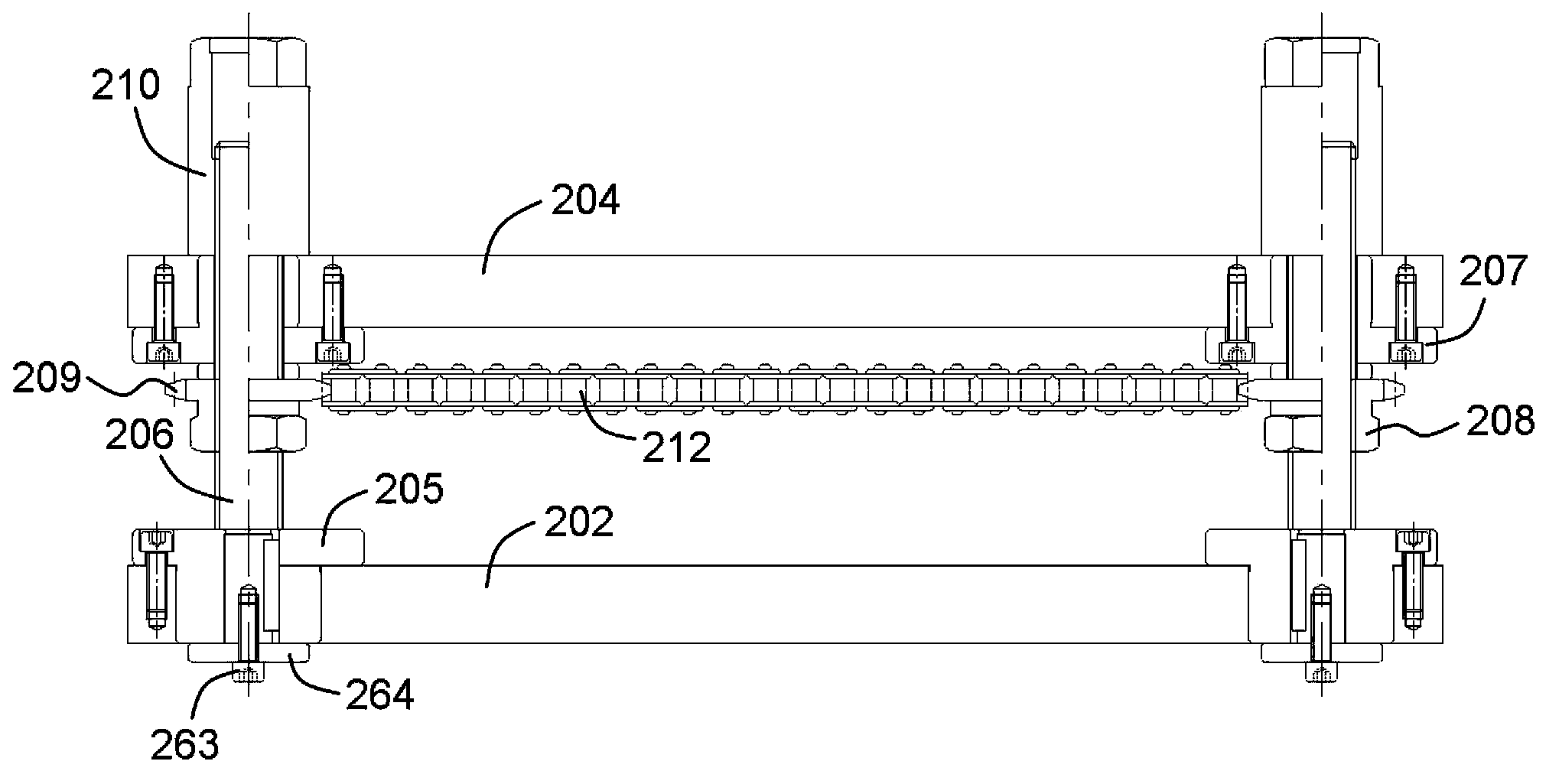

[0029] refer to figure 2 as shown, figure 2 Disclosed is a structural diagram of a transmission belt tensioner according to an embodiment of the present invention.

[0030] Such as figure 2 As shown, the transmission belt tensioning device includes: a bottom plate 202 , a top plate 204 , a screw rod 206 , a driving nut 208 and four nut sleeves 210 . The four corners of the bottom plate 202 are provided with support holes, and the four corners of the top plate 204 are provided with installation holes, and the positions of the installation holes correspond to the positions of the support holes. The screw rod 206 , the driving nut 208 and the nut sleeve 210 are installed on the four corners of the bottom plate 202 and the top plate 204 respectively, so the number of the screw rod 206 , the driving nut 208 and the nut sleeve 210 are four.

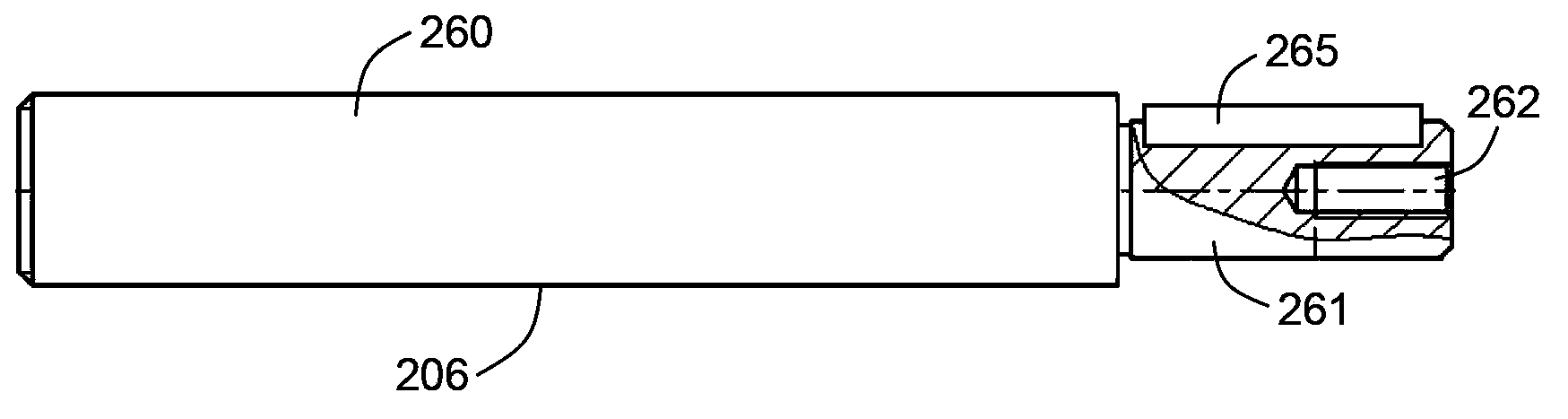

[0031] The bottom of each screw 206 in the four screws 206 is installed in a support hole, and the top passes through a corresponding in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com