Multivariable cooperative control method for double-hearth circulating fluidized bed unit

A circulating fluidized bed and collaborative control technology, which is applied to the control of bed temperature and bed pressure, and the field of circulating fluidized bed boiler load, can solve the problems of difficulty in controlling the balanced combustion of double furnaces and poor stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126] The present invention will be further described below in conjunction with the accompanying drawings.

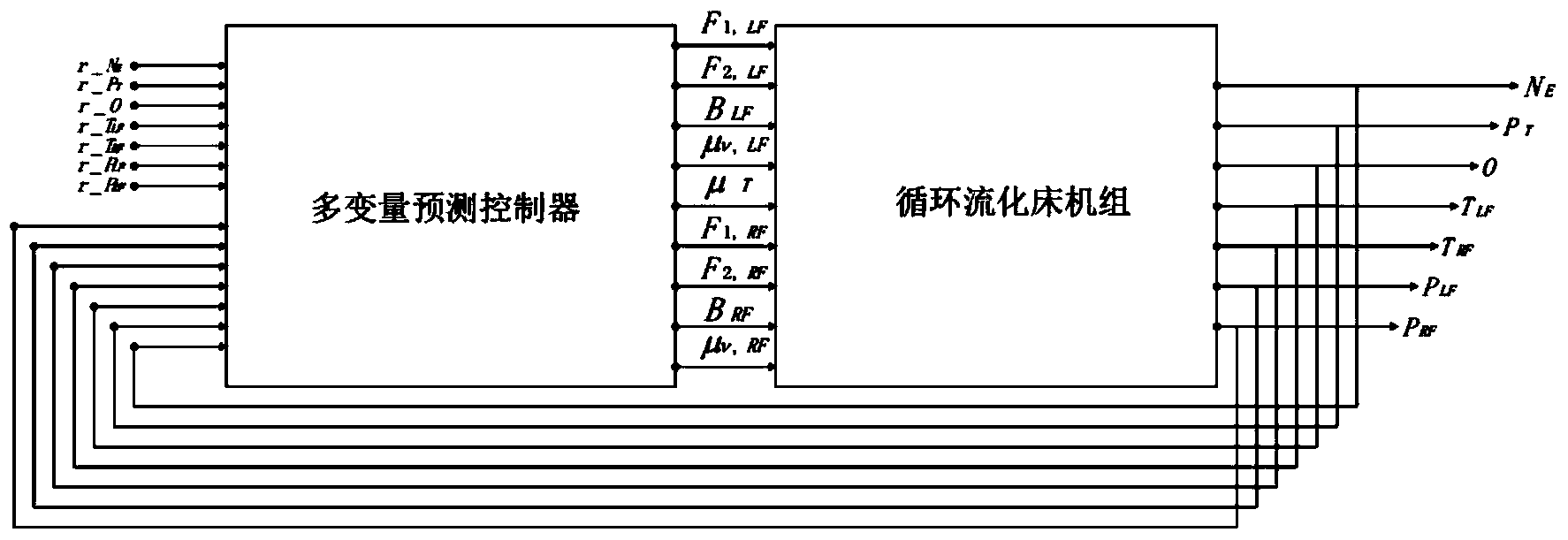

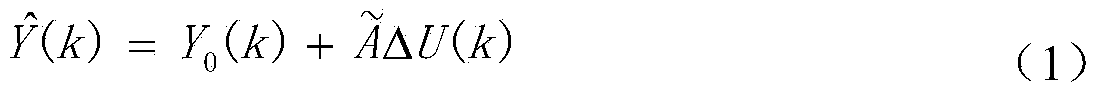

[0127] exist figure 1 In the output Y of the system, there are a total of 7 output quantities, which are the real power N E , Front pressure P T , oxygen content O, left hearth temperature T LF , right hearth temperature T RF , left hearth pressure P LF and right hearth pressure P RF , the prefix r indicates their setting value; the input U of the system has a total of 9 input quantities, which are the primary air volume of the left furnace F 1,LF , Left furnace secondary air volume F 2,LF , Left furnace coal supply B LF , The opening degree of the return valve of the left furnace μ v,LF , The opening degree of the main steam control valve μ T , Primary air volume of the right furnace F 1,RF , The secondary air volume of the right furnace F 2,RF , Right furnace coal supply B RF and the opening of the right furnace return valve μ v,RF . In this way, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com