A system and method for preventing boiler explosion

A boiler and furnace technology, which is applied in the field of boiler explosion prevention systems, can solve problems such as equipment damage, furnace wall damage, and external explosion, and achieve the effect of protecting the furnace.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

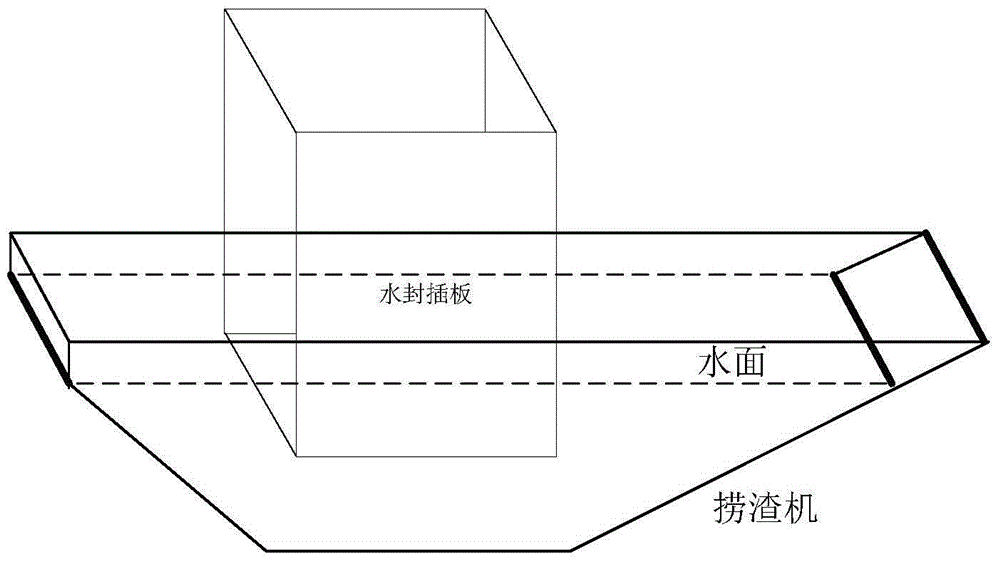

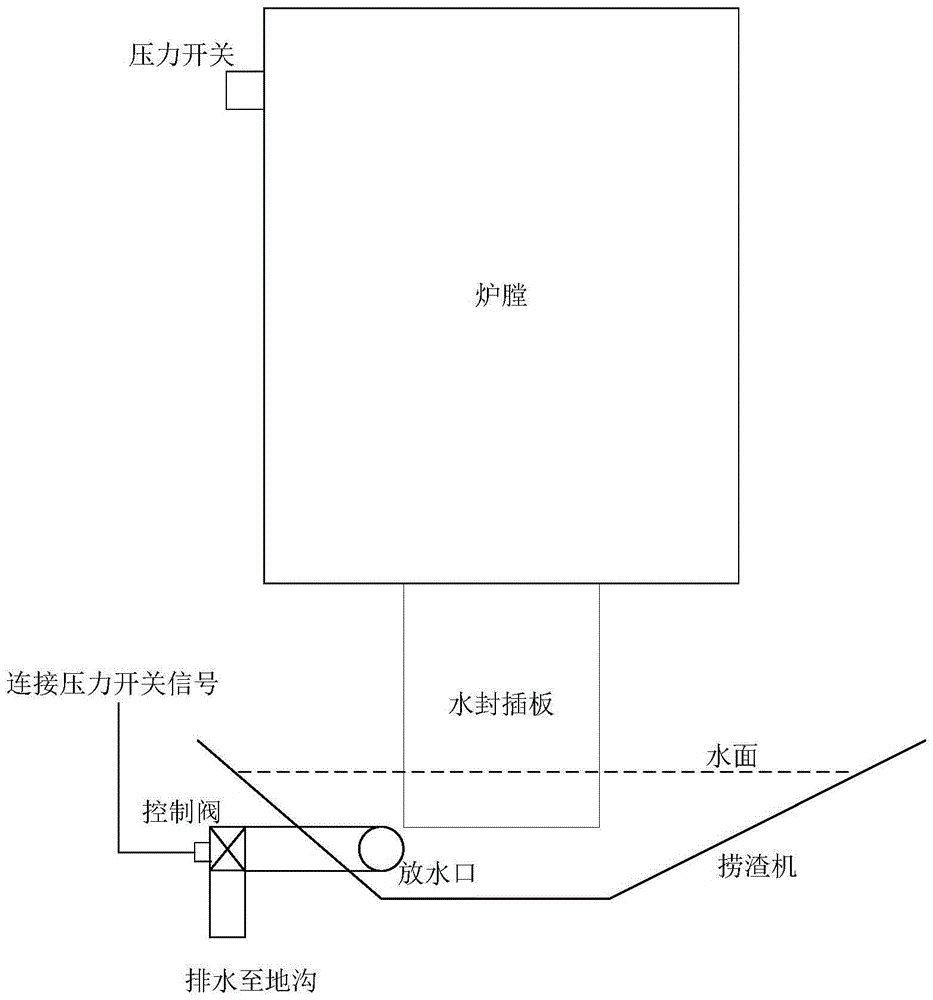

[0018] Such as figure 1 As shown, the solid-state slagging coal-fired boiler generally adopts a wet slagging process. A slag removal machine is installed at the bottom of the boiler furnace. A certain water level is maintained in the slag removal machine. The depth of the furnace prevents the cold air from leaking into the boiler and isolates the combustion space of the boiler from the open space of the furnace bottom. The slag generated by the combustion in the furnace falls into the water tank and is cooled rapidly, and then is dragged out of the water surface by the scraper of the slag extractor and transported to the designated position, thus ensuring the continuous and safe operation of the boiler.

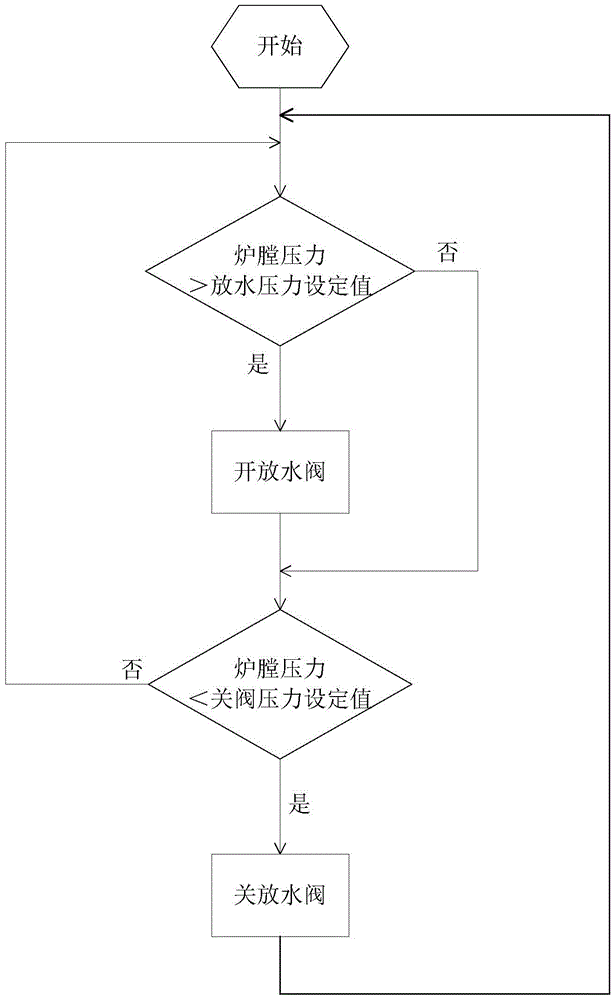

[0019] However, in some cases of abnormal combustion, there will be a large pressure change in the combustion space in the furnace, sometimes the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com