A method for improving the utilization efficiency of cooling capacity during liquefied natural gas gasification

A technology of liquefied natural gas and liquefied natural gas, which is applied in applications, heating methods, household appliances, etc., can solve the problems of long cold water transportation distance, low cooling conversion efficiency, and many heat exchange processes, so as to reduce the use of pipelines and pumps, High utilization efficiency of cooling capacity and the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

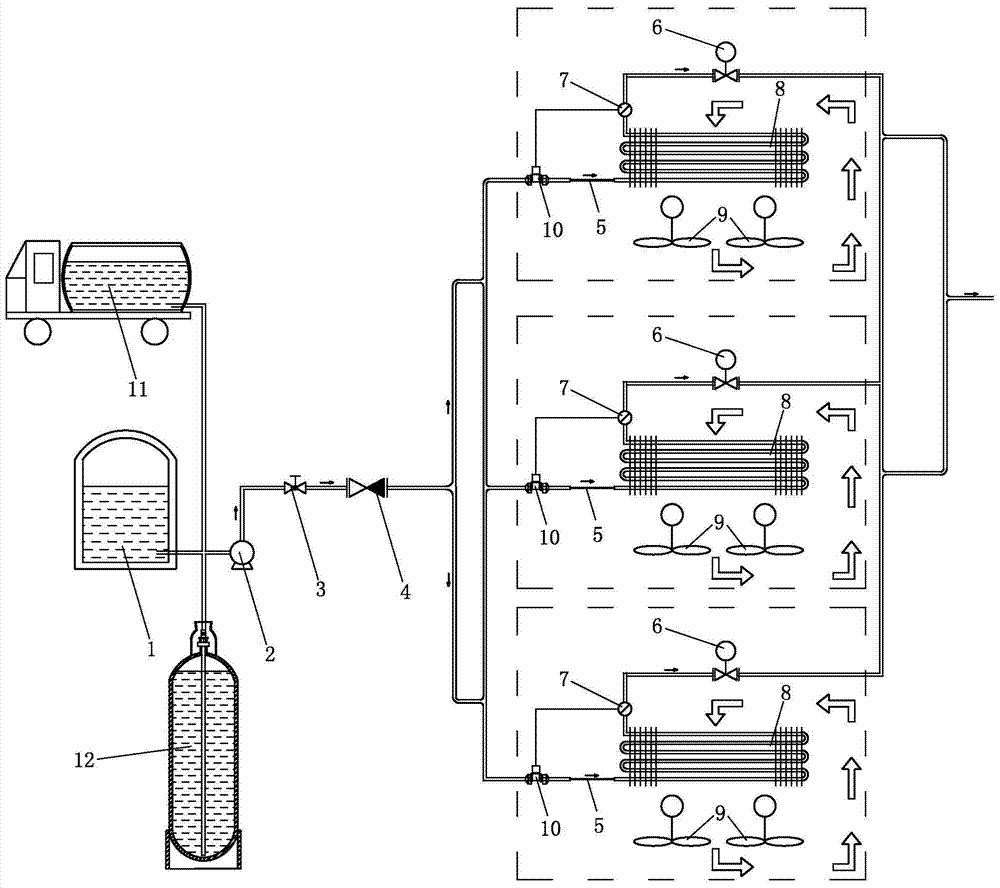

[0017] like figure 1 Shown is the process flow diagram of the utilization method of the cooling capacity when the liquefied natural gas is gasified in the present invention, the cooling capacity utilization method of the present invention is as follows: the liquefied natural gas at -160 ° C is transferred from the low-temperature liquid storage tank 1 or the tank car 11 of the liquefied natural gas station or The liquefied natural gas cylinder 12 is pressurized by the pump 2 (pressurized to 0.5-0.8 MPa), passes through the stop valve 3 and the check valve 4, and then is transported to the capillary 5 through the pipeline. Pipe 8, the liquefied natural gas can be turned into gaseous natural gas without any external energy in the coil 8, the natural gas absorbs heat in the process of changing from liquid to gas, so that the temperature of the coil 8 decreases, and the temperature of the air around the outer wall of the coil 8 decreases, The fan 9 located directly below the coil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com