Electric main shaft dynamic balance performance test experimental system

A technology of test experiment and electric spindle, which is applied in the field of monitoring experiment system, can solve the problems of low test speed, unbalanced electric spindle, difficulty in satisfying the environment simulation of high-speed electric spindle, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

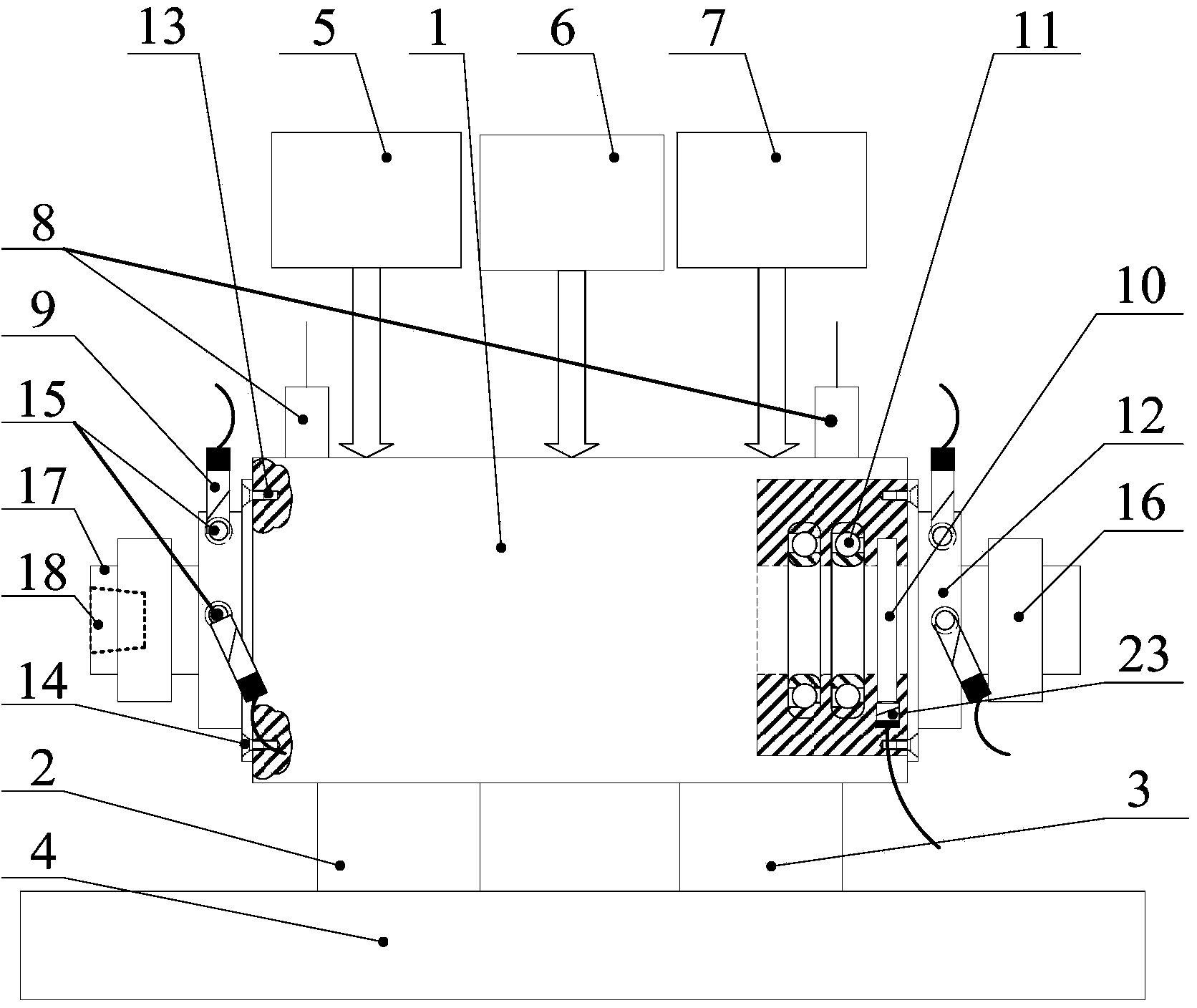

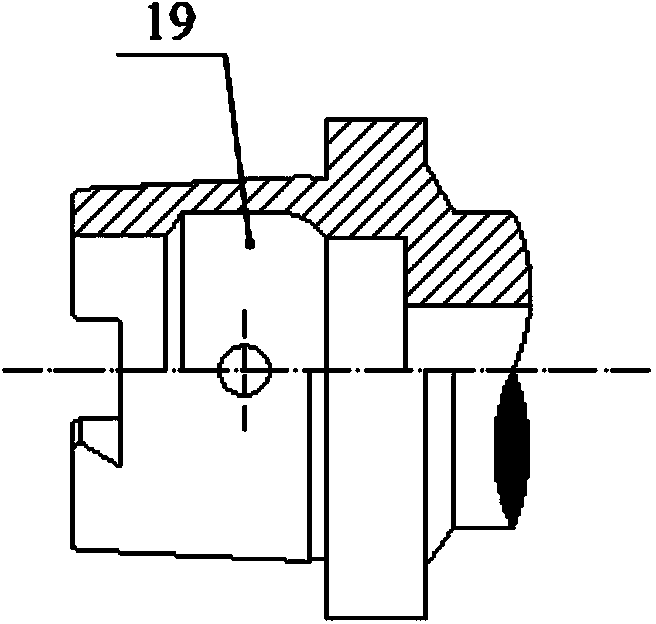

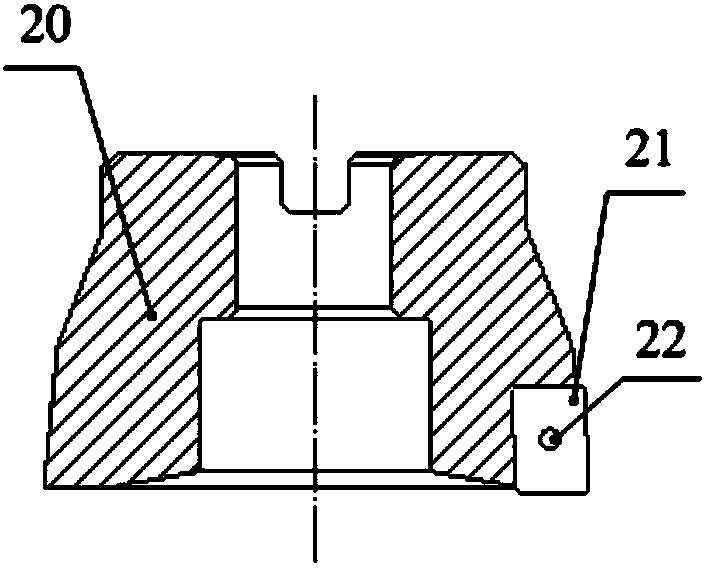

[0035] The present invention is described in further detail below in conjunction with accompanying drawing:

[0036] refer to figure 1 , figure 2 , image 3 and Figure 4 , the electric spindle dynamic balance performance testing experimental system of the present invention includes a vibration reduction test bench 4, a high-speed electric spindle 1, several balance weights, four vibration displacement sensors 9, two vibration acceleration sensors 8, a high-speed rotational speed sensor 10, Two vibration displacement sensor brackets 12, two dynamic balance adjustment discs 16, cutters, synchronous data acquisition card 25, computer 29, variable frequency drive 5 for adjusting the speed of the rotor 17 on the high-speed electric spindle 1, for adjusting the speed of the high-speed electric spindle The oil-air lubricator 6 for oil-air lubrication of the bearing 11 of 1, and the circulating cooler 7 for cooling the high-speed electric spindle 1.

[0037]The high-speed electr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap