Denitration device potential assessment and prediction method based on field performance tests

A technology of field performance and prediction method, applied in the direction of measurement device, machine/structural component test, instrument, etc., can solve the problem of affecting NOx emission standard, catalyst replacement time lag, prolong catalyst detection cycle and other problems, achieve accurate prediction, improve The effect of applying depth and reducing operational impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

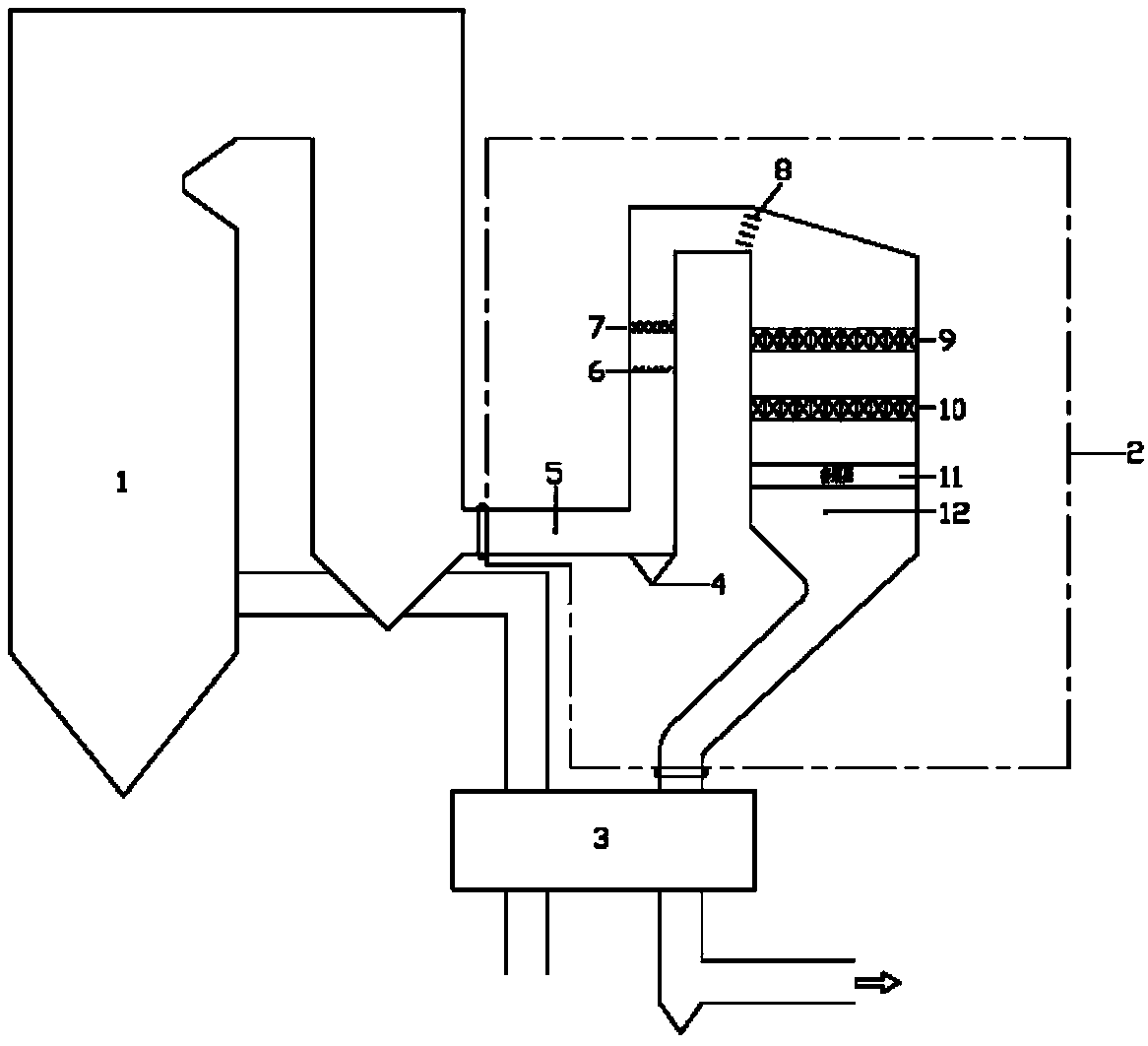

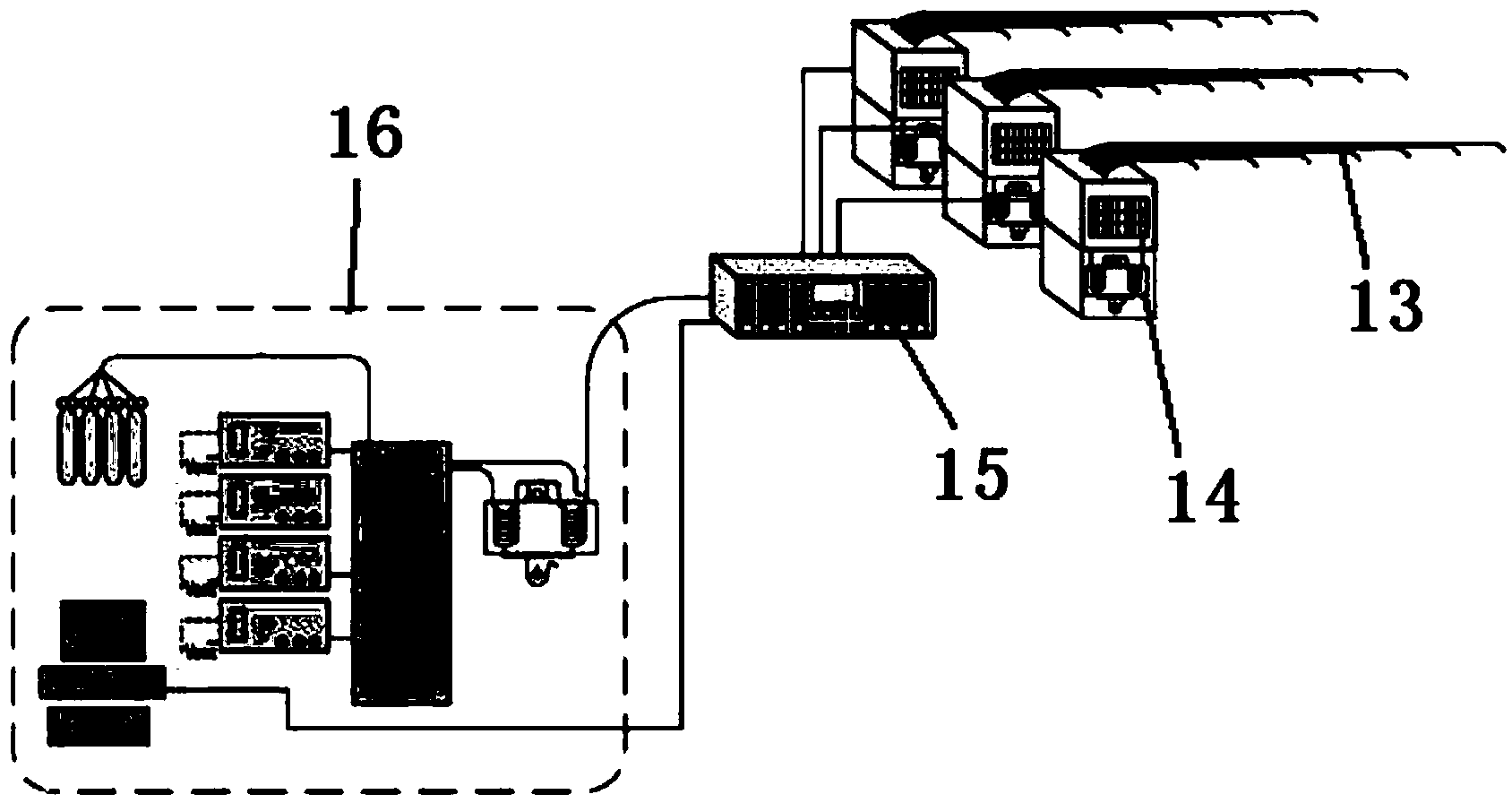

[0031] The present invention will be further elaborated below. The present invention is completed on the basis of laboratory pilot test and local on-line detection of denitrification catalyst performance, theoretical analysis and verification of a large number of field test data. It mainly went through the following processes:

[0032] 1) Analysis of existing detection methods

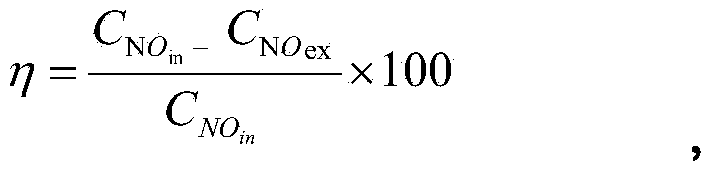

[0033] The present invention first analyzes the existing flue gas denitrification catalyst activity (or device potential) detection method: based on the NH in the flue gas 3 The / NO molar ratio is 1.0. The German E.ON company used the laboratory pilot test platform and the US FERco company used the local online catalyst of the denitrification device to measure the denitrification efficiency of the single-layer catalyst unit sample, and calculated the catalyst activity by using the denitrification efficiency method; Cormetech uses the laboratory pilot test platform to measure the denitrification effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com