Silicon wafer hardness testing device

A hardness test, silicon wafer technology, applied in the direction of testing material hardness, etc., can solve the problems of silicon wafer fragmentation, difficult to grasp manual operation force, inconvenient and laborious, etc., to achieve uniform test pressure, avoid crushing, and accurately measure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

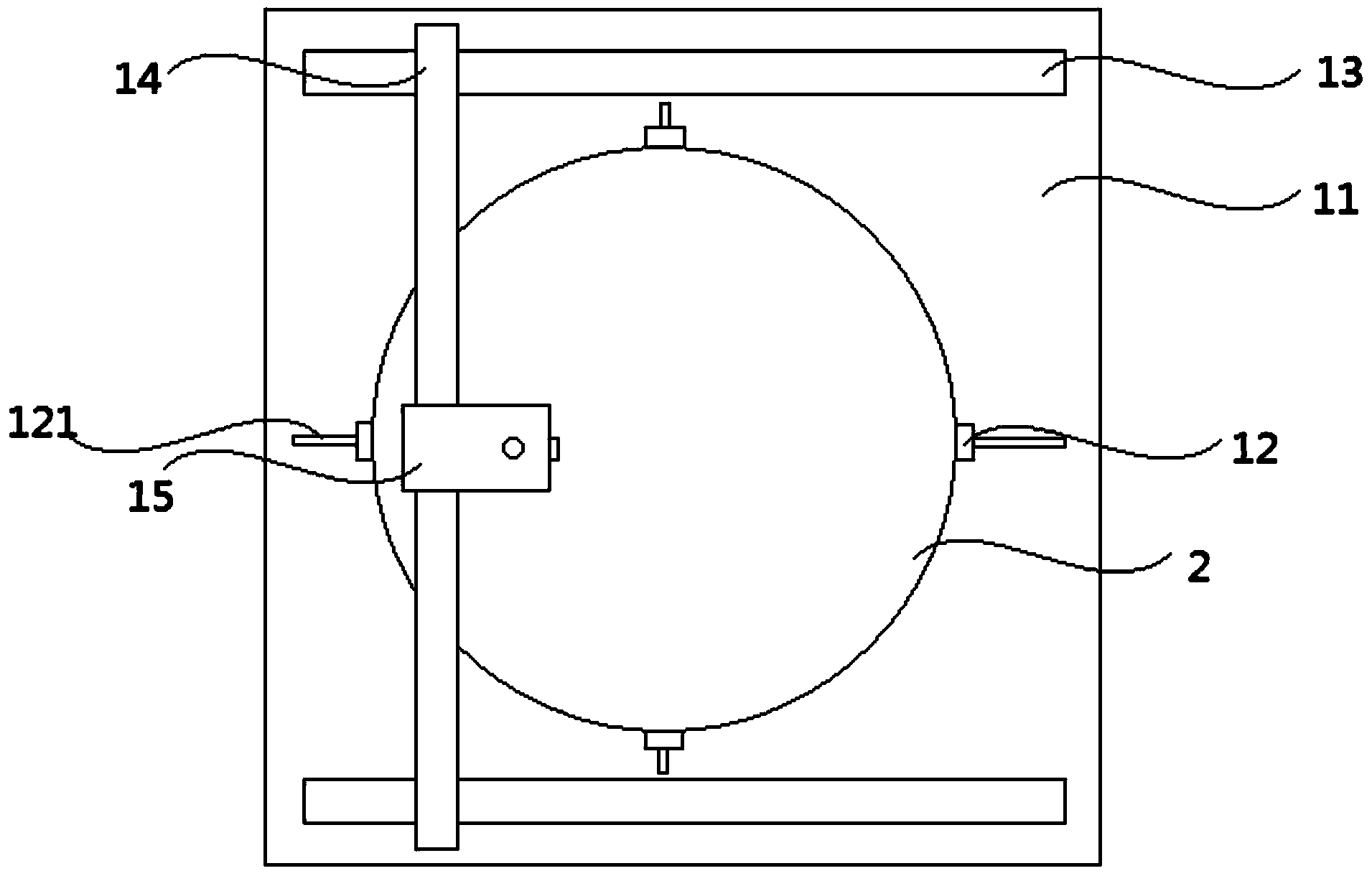

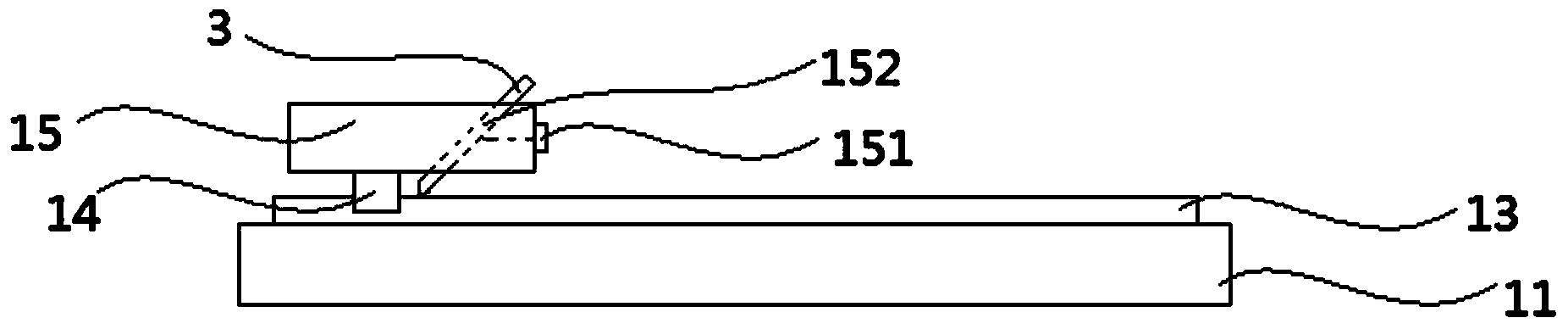

[0026] see figure 1 with figure 2 , the silicon wafer hardness testing device of the present embodiment comprises:

[0027] The test base 11 is used to carry the tested silicon wafer 2;

[0028] Silicon chip holder 12, located on the test base 11, used to clamp and fix the silicon wafer 2 on the test base 11;

[0029] The transverse track 13 is fixed on the test base 11;

[0030] The longitudinal track 14 is arranged on the transverse track 13 and has a connecting portion slidingly connected with the transverse track 13, so that the longitudinal track 14 can translate along the transverse track 13;

[0031] The pencil test module 15 is arranged on the longitudinal rail 14, and has a connecting portion slidingly connected with the longitudinal rail 14, so that the pencil test module 15 can translate along the longitudinal rail 14. The pencil test module 15 also includes a pencil holder 151 for Clamp and fix different pencils 3 (such as 2H to 9H) to test the hardness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com