Buried-steel-pipeline-based magnetic anomaly extraction and interpretation method

A magnetic anomaly and pipeline technology, applied in pipeline systems, material magnetic variables, special data processing applications, etc., can solve problems such as the inability to exclude external interference anomalies, the inability to distinguish the location of stress concentration areas in the pipe body, and the limitation of development and promotion speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below with reference to the drawings and embodiments.

[0046] The technical solution adopted by the present invention to solve its technical problems is: providing a method for extracting and explaining magnetic anomalies based on buried steel pipelines, which specifically includes the following steps:

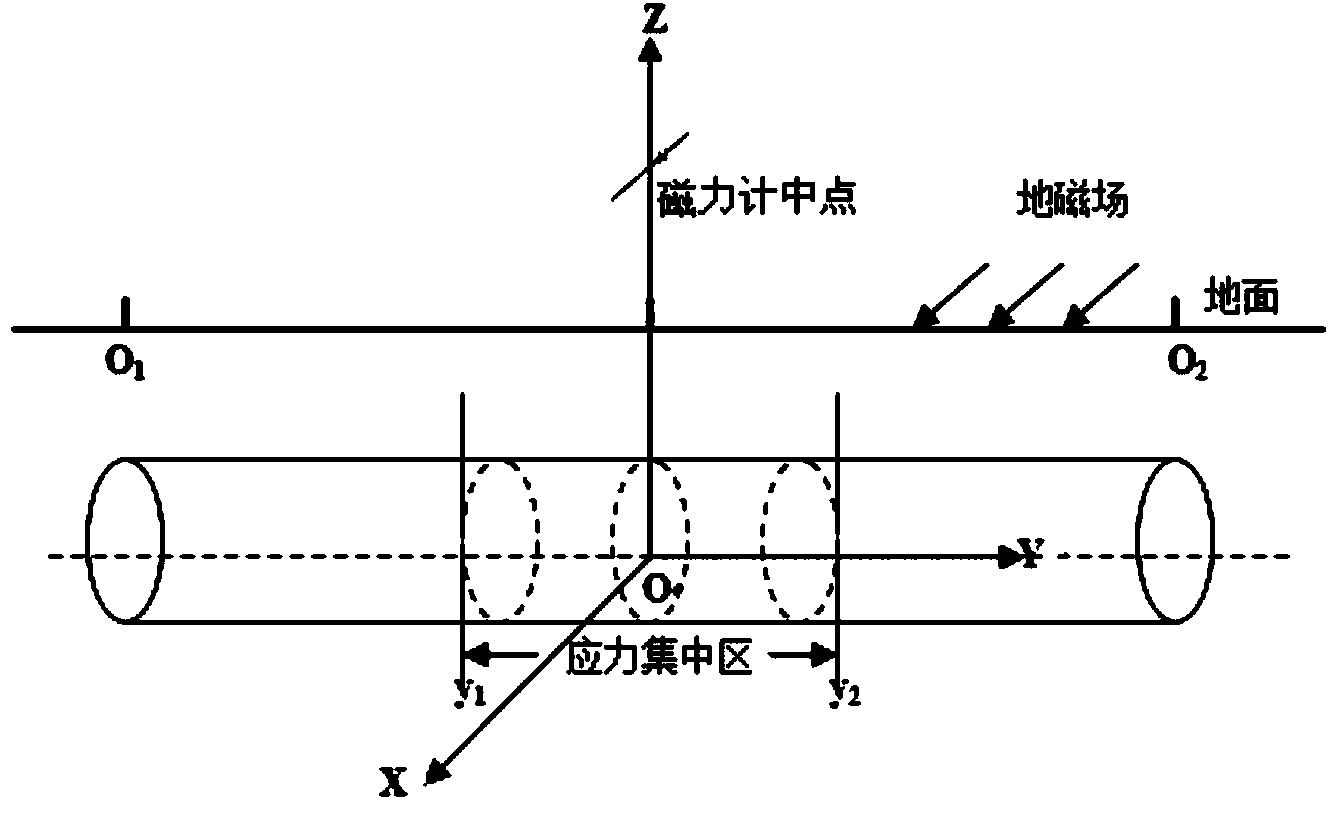

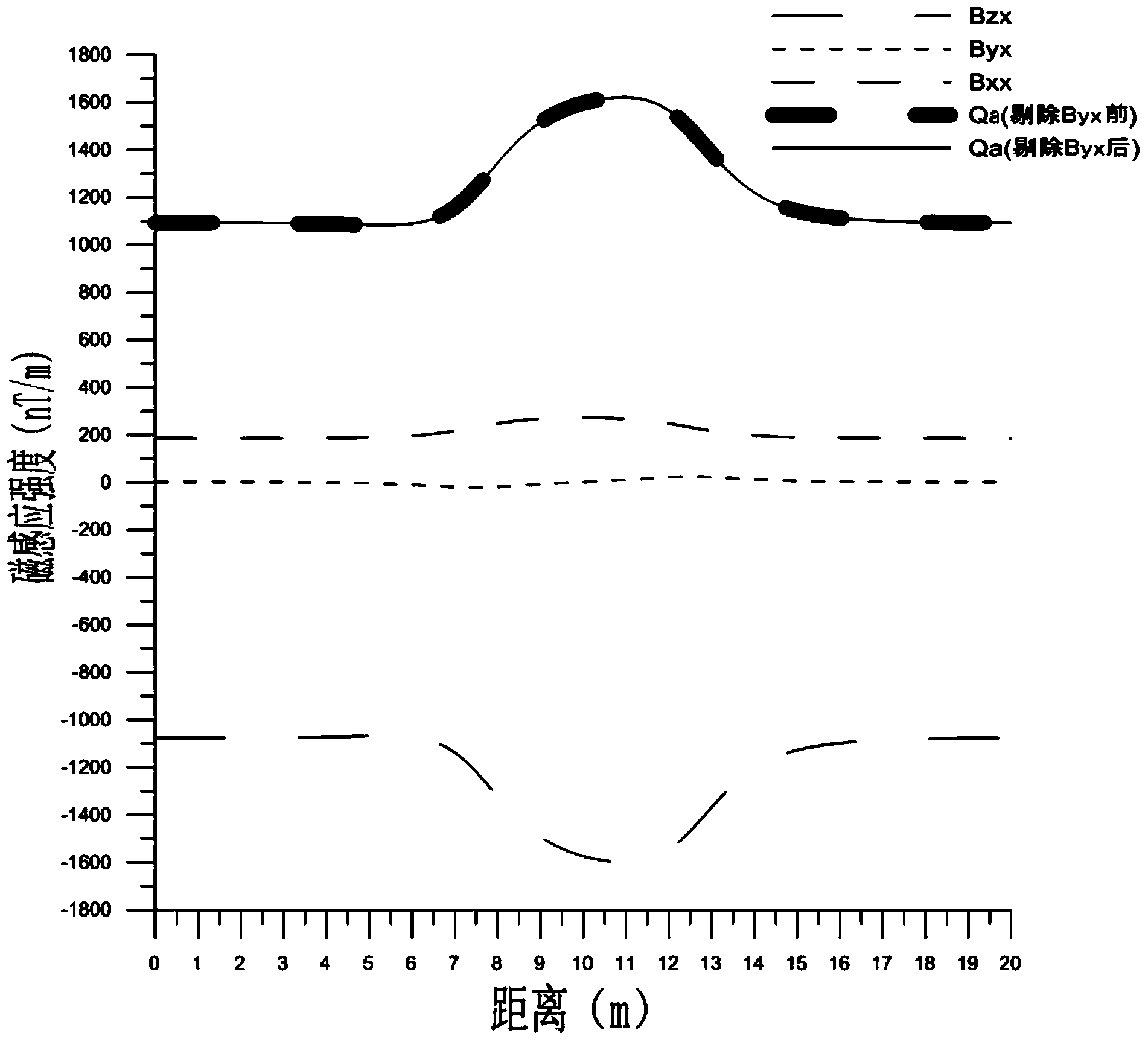

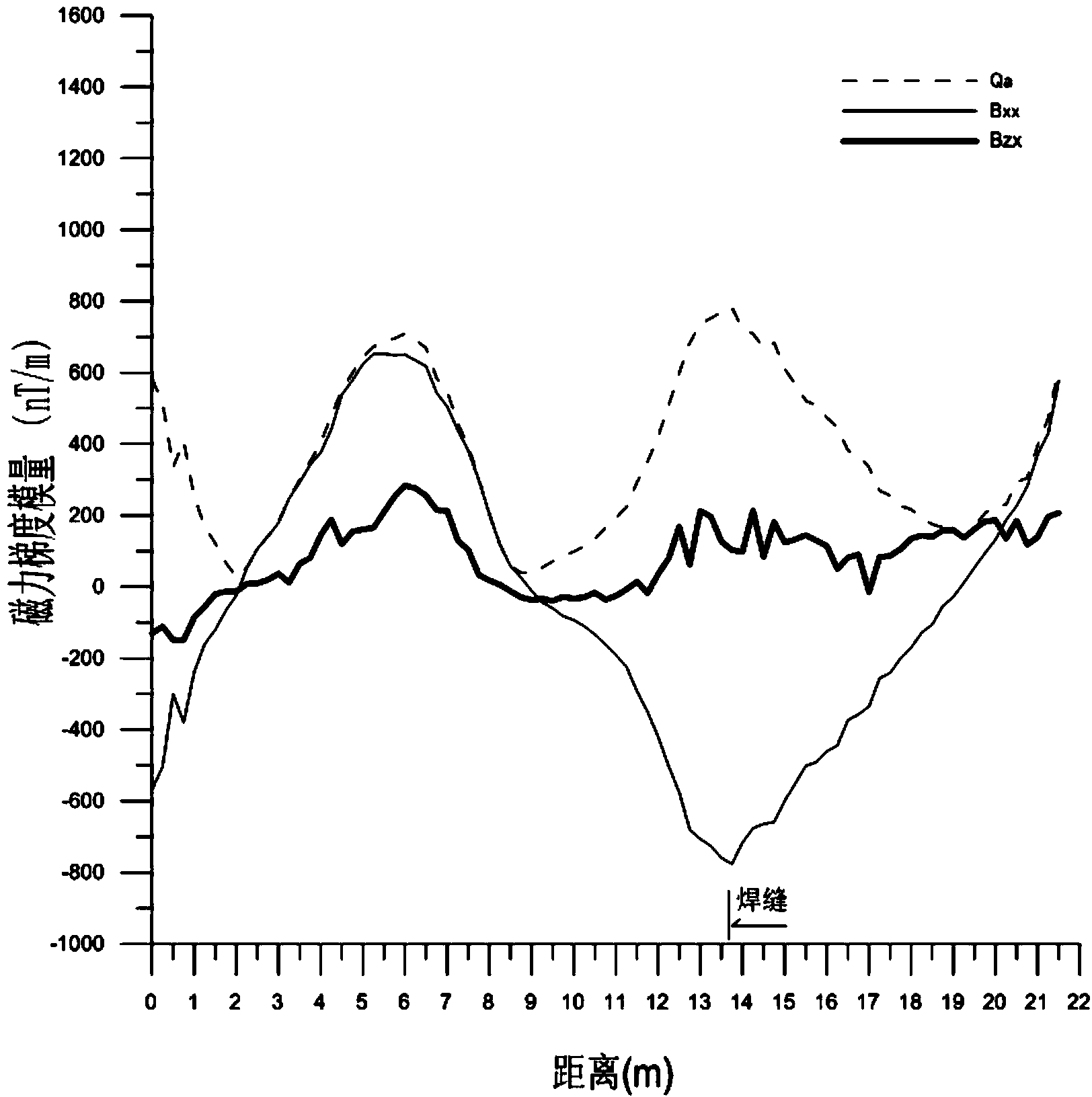

[0047] (1) Use a magnetometer to use non-contact pipeline magnetic detection technology to measure the magnetic induction intensity of the pipeline along the axial direction to obtain a three-component horizontal gradient B xx , B yx And B zx The change law curve along the axial distribution of the pipeline.

[0048] (2) Use the following formula to eliminate B yx To reduce the external interference anomaly, and calculate the risk index F based on the measured modulus value and the average modulus value after removing the interference anomaly:

[0049] F = e ( 1 - Q a Q ‾ ) . . . . . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com