Weather-proof improved wire

A weather and conductor technology, applied in plastic/resin/wax insulators, organic insulators, conductors, etc., can solve the problems of high power consumption, short service life, and easy leakage of ordinary outdoor wires, and improve power supply quality and long service life. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

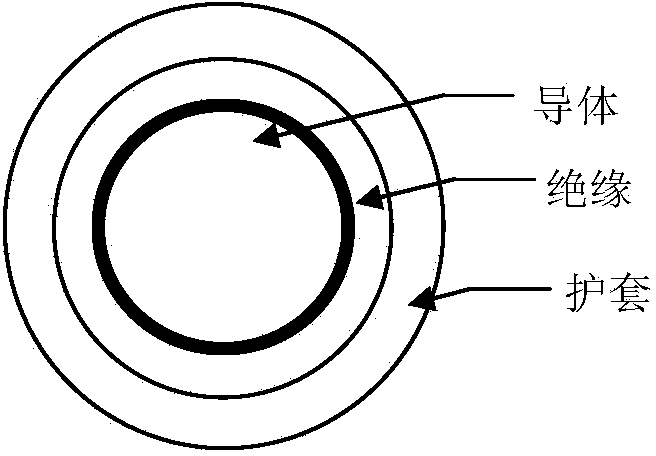

[0021] The structure of the weather-improved thread of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the weather-improved wire includes a conductor 1 extruded on the outer layer of the conductor 1 with an insulating layer 2 and a sheath 3 wrapped around the outer layer of the insulating layer 2. The wire 1 is a single wire, and the wire 1 is a single wire. The insulating layer 2 is made of weather-resistant polyvinyl chloride material, and the sheath 3 is made of low-density polyvinyl chloride added with a light shielding agent.

[0023] The weather-resistant polyvinyl chloride is prepared by adding 35-40 parts of tricresyl phosphate to polyvinyl chloride.

[0024] The light shielding agent is carbon black.

[0025] The conductor is copper wire or aluminum wire.

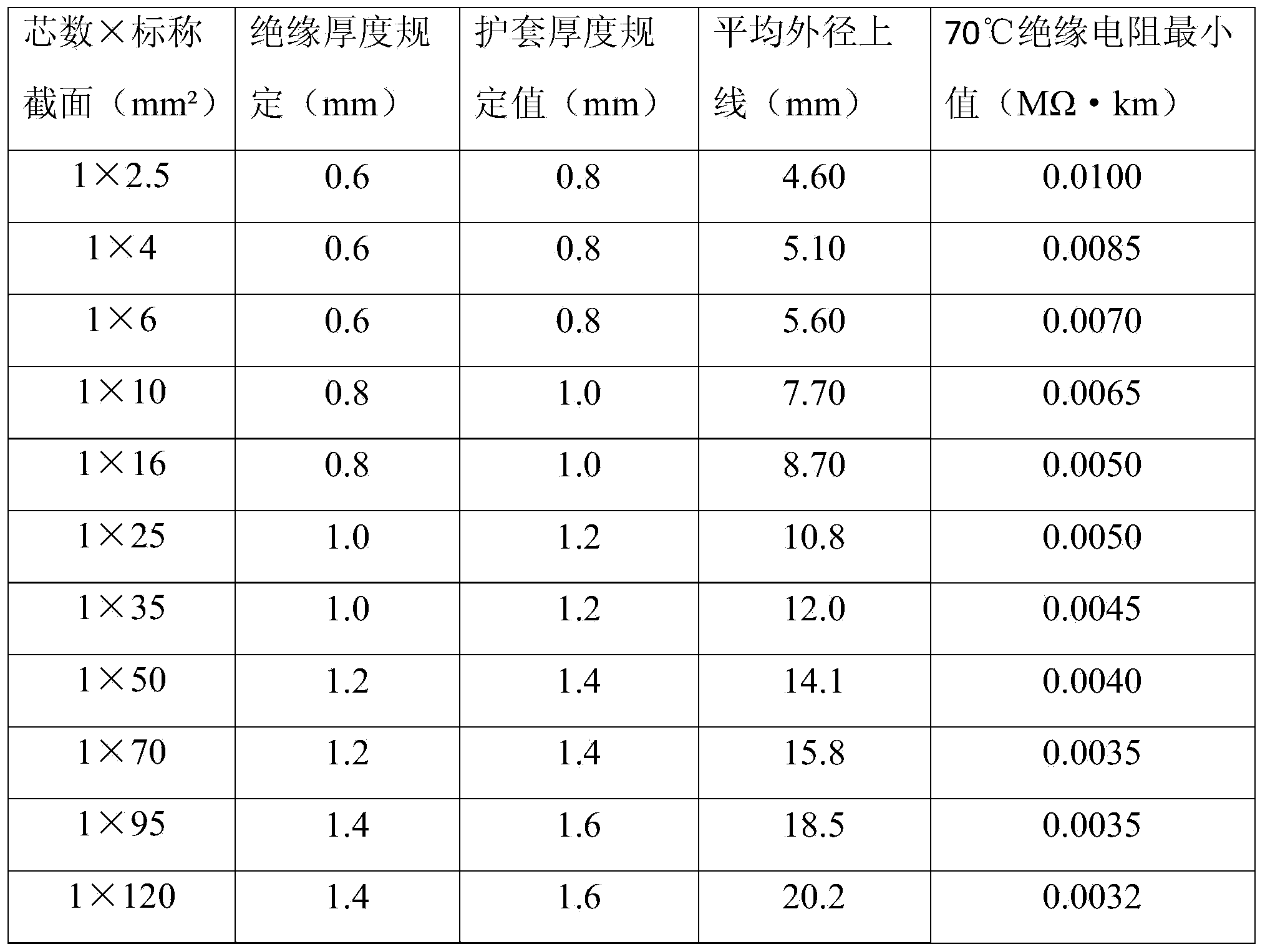

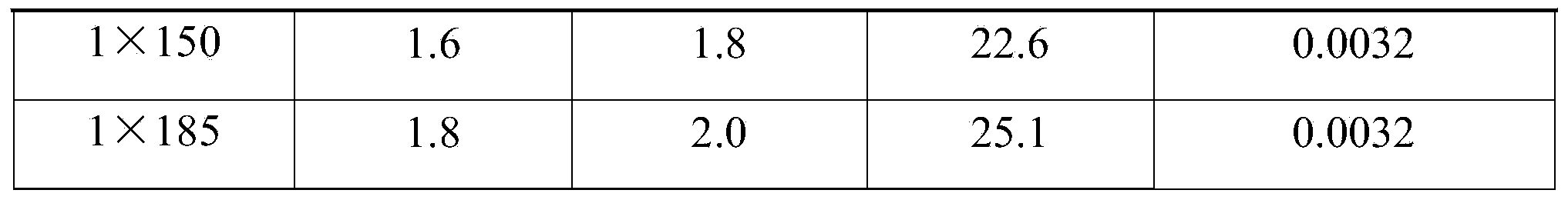

[0026] The following table (table 1 / table 2) shows the type, size and performance of the copper core wind and rain impro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com