A Dewar system for high temperature superconducting magnetic levitation energy storage flywheel

A high-temperature superconducting, energy storage flywheel technology, applied in superconducting magnets/coils, magnetic objects, holding devices with magnetic attraction or thrust, etc., can solve the problem that the liquid nitrogen Dewar system cannot meet the high temperature superconducting magnetic suspension energy storage flywheel and other problems to achieve a stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

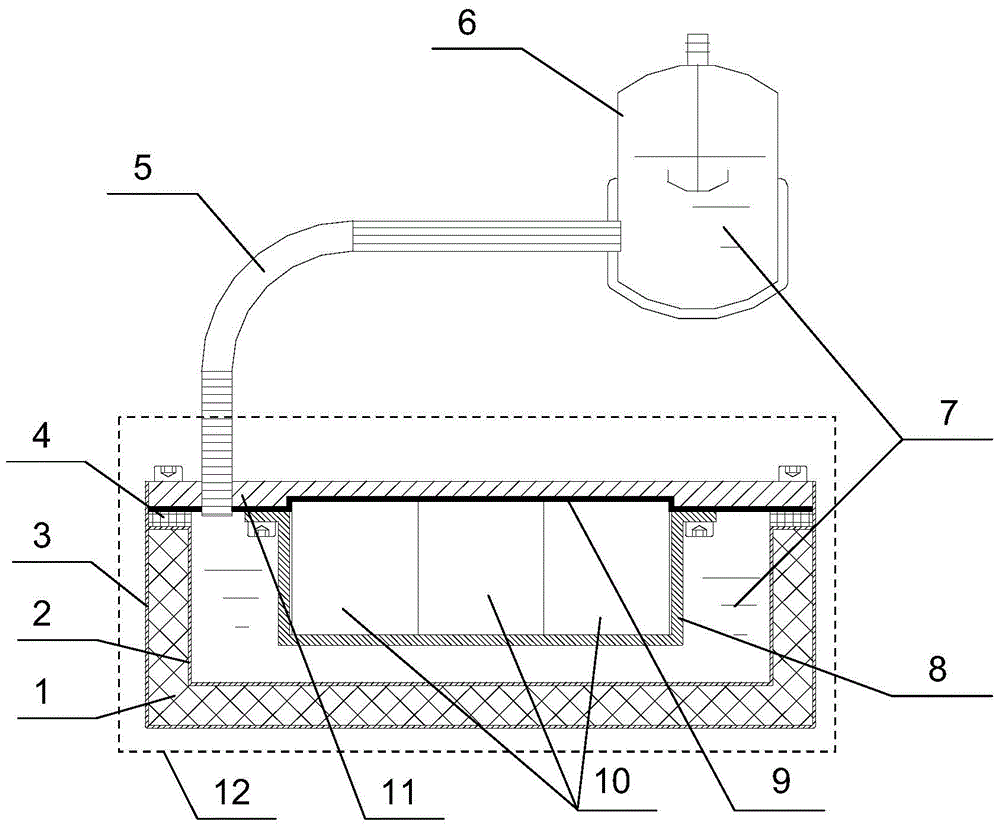

[0022] Such as figure 1 As shown, it is a block diagram of the structure of the present invention, which is composed of an external liquid nitrogen container 6 and a Dewar bottle 12 providing a low temperature environment. The external liquid nitrogen container 6 and the Dewar bottle 12 are connected through the liquid nitrogen connector 5, the external liquid nitrogen container 6 is filled with liquid nitrogen 7, and the liquid nitrogen 7 is added to the Dewar bottle 12 through the liquid nitrogen connector 5; The tile bottle 12 is composed of a Dewar inner wall 2, a Dewar outer wall 3, a vacuum filling material 1 between the Dewar inner wall 2 and the Dewar outer wall 3, an insulating sealing ring 4, a superconducting block support 8, an insulating coating layer 9, high temperature superconducting block assembly 10 and upper end cap 11. The vacuum filling material 1, the inner wall 2 of the Dewar bottle and the outer wall 3 of the Dewar bottle constitute the base and the pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com