Conduction cooling high temperature superconducting electric-magnetic iron remover based on nitrogen fixation protection

An electromagnetic iron remover, high temperature superconducting technology, applied in superconducting magnets/coils, open gradient separators, circuits, etc., can solve the problems of uncontrollable, low magnetic force, single magnetic field direction, etc., to improve the stability of the magnet , high magnetic force, reliable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

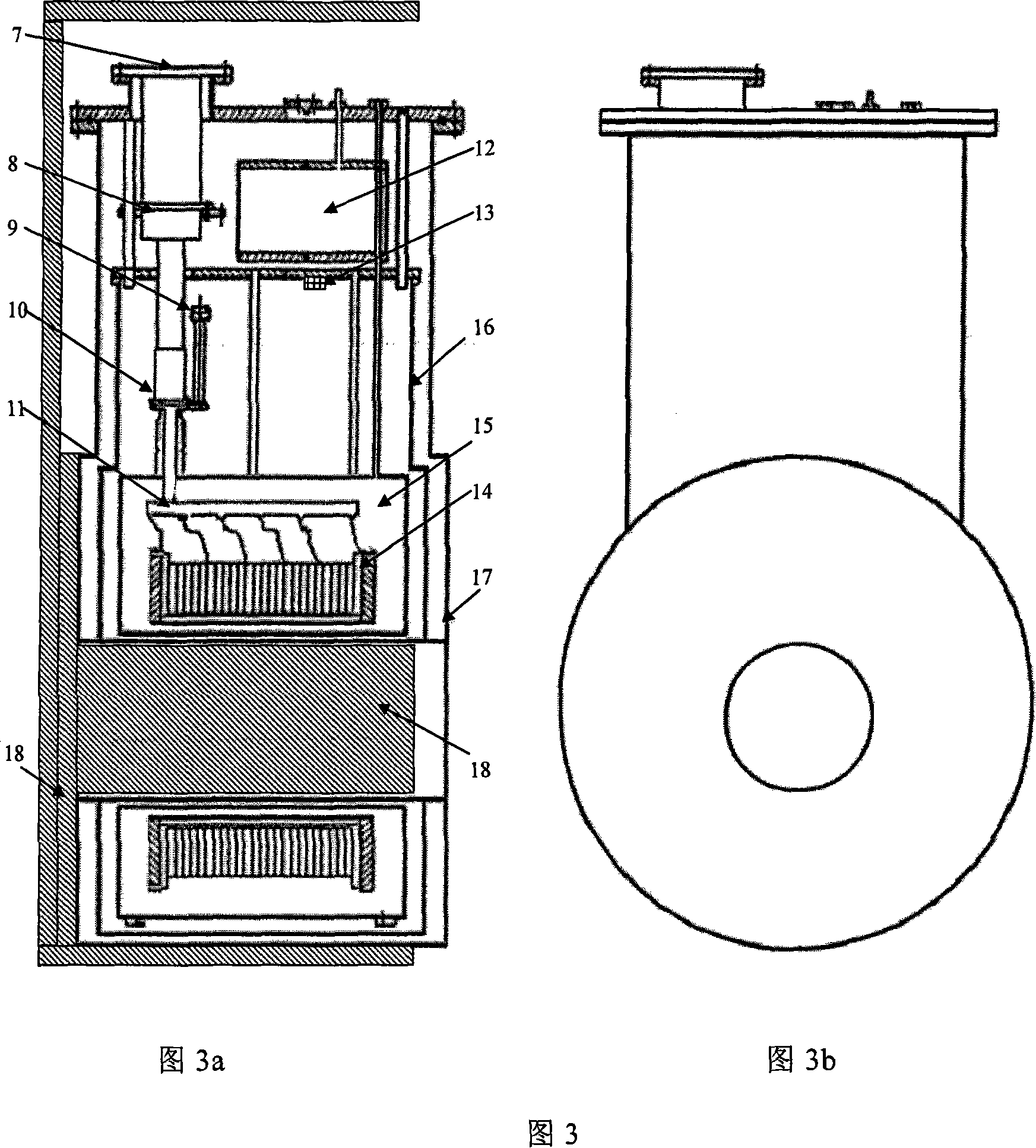

[0056] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

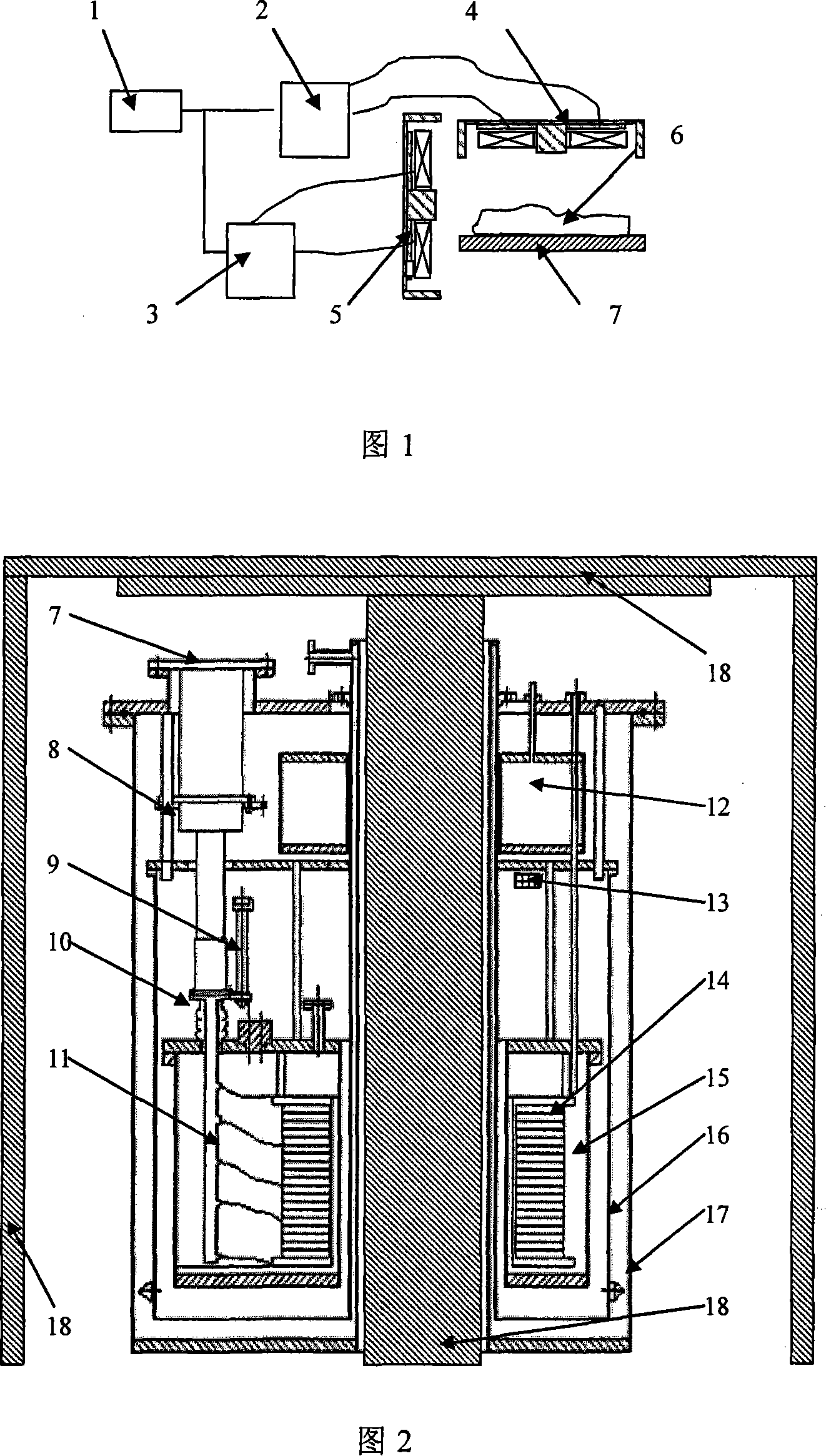

[0057] Fig. 1 is a schematic diagram of the composition and structure of the high temperature superconducting iron remover for nitrogen fixation protection of the present invention. The high temperature superconducting iron remover for nitrogen fixation protection of the present invention is composed of a magnetic field control computer 1, a vertically programmed power supply 2, a horizontally programmed power supply 3, a vertically superconducting magnet 4, and a horizontally superconducting magnet 5, which can remove the coal seam 6 on the conveyor belt 7 The ferromagnetic impurities in the

[0058] The magnetic field control computer 1 completes the functions of magnetic field calculation and status monitoring. The serial port of the magnetic field control computer 1 is connected to the serial ports of two program-controlled superconducting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com