Cooling-down humidity-control system

A technology for electrical controllers and air outlets, applied in heating and ventilation control systems, air-conditioning systems, heating and ventilation safety systems, etc., can solve the problems of ozone-depleting gases and greenhouse gases, high operating costs of air-conditioning, and reduce power consumption , The effect of saving operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

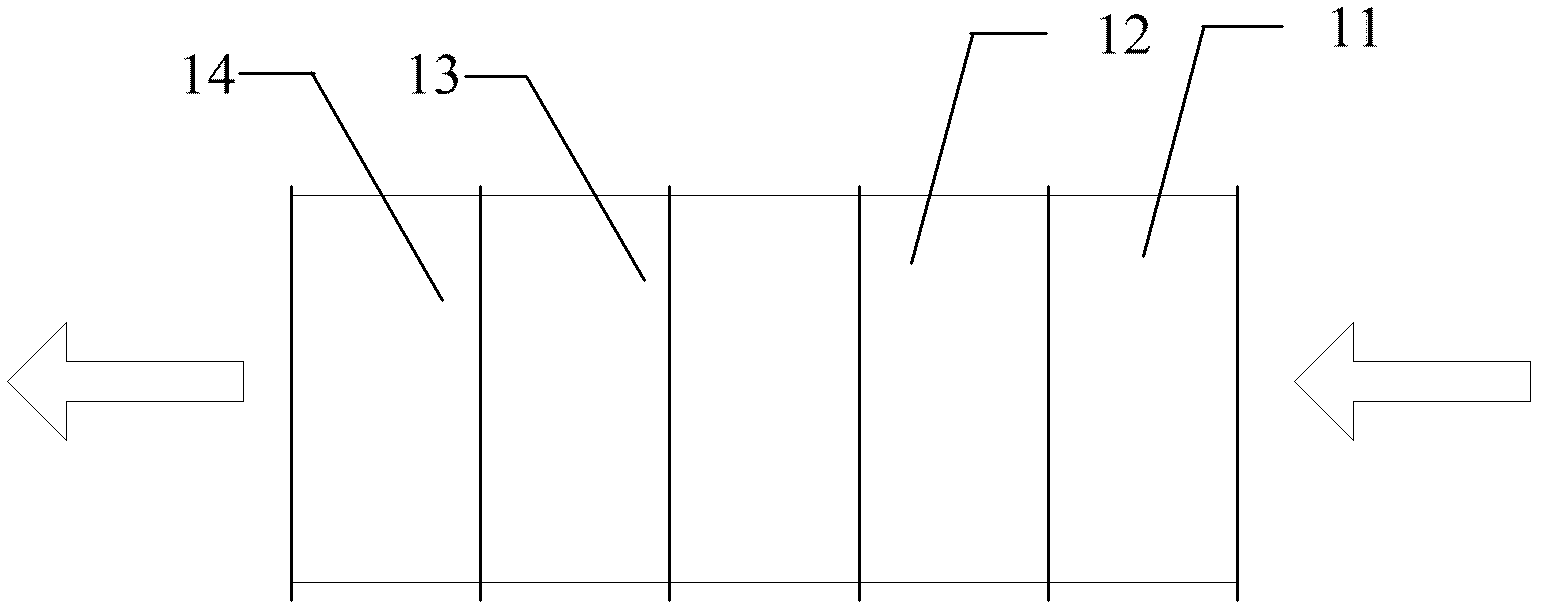

[0020] The structure of the cooling and humidity control system provided by the first embodiment of the present invention is as follows: figure 1 As shown, the system includes: a return air module 11 , a spray module 12 , a dehumidification module 13 and an air supply module 14 . The air outlet of the return air module 11 is connected to the air inlet of the spray module 12 , the air outlet of the spray module 12 is connected to the air inlet of the dehumidification module 13 through a ventilation duct, and the air outlet of the dehumidification module 13 is connected to the air inlet of the air supply module 14 . The return air module 11 and the air supply module 14 are installed with fans with appropriate air volume according to the ventilation volume requirements of the application site. The return air fan is installed in the return air module 11, and the air supply fan is installed in the air supply module 14. Install a high-pressure water pump with appropriate flow and se...

Embodiment 2

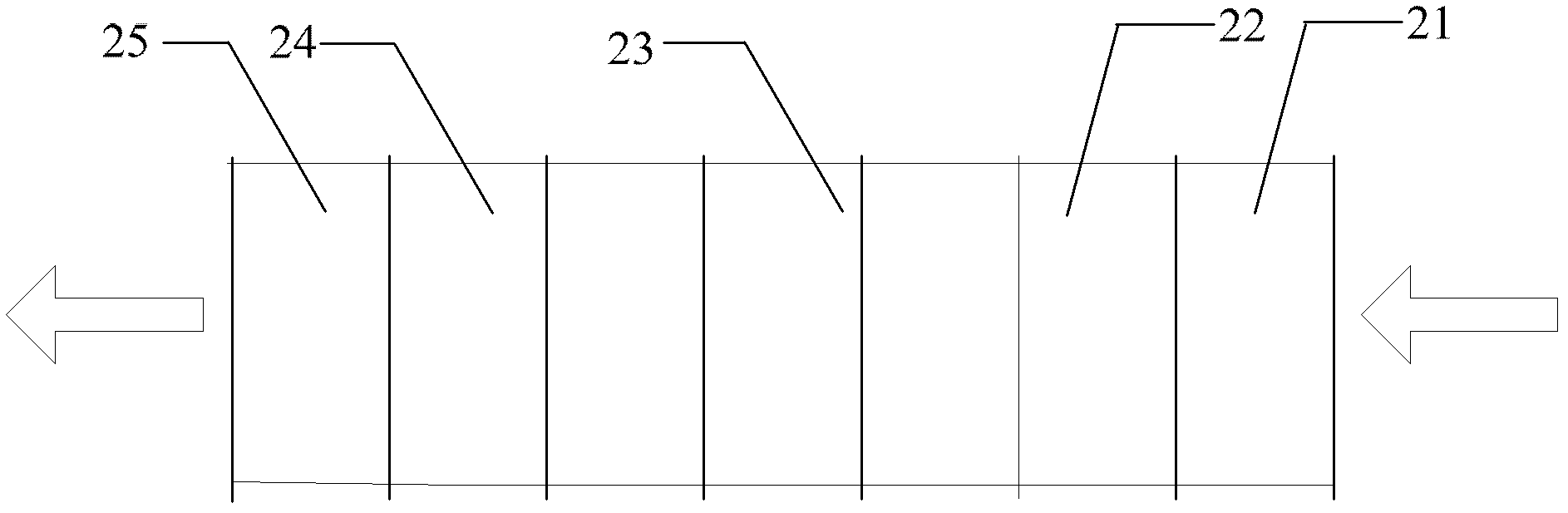

[0031] The structure of the cooling and humidity control system provided by the second embodiment of the present invention is as follows: figure 2 As shown, the system includes: a return air module 21 , a spray module 22 , a filter module 23 , a dehumidification module 24 and an air supply module 25 . The air outlet of the return air module 21 is connected to the air inlet of the spray module 22, the air outlet of the spray module 22 is connected to the air inlet of the filter module 23 through the ventilation duct, and the air outlet of the filter module 23 is connected to the air inlet of the dehumidification module 24 through the ventilation duct Connection, the air outlet of the dehumidification module 24 is connected to the air inlet of the air supply module 25 . The return air module 21 and the air supply module 25 are installed with fans of appropriate air volume according to the ventilation volume requirements of the application site. The return air fan is installed i...

Embodiment 3

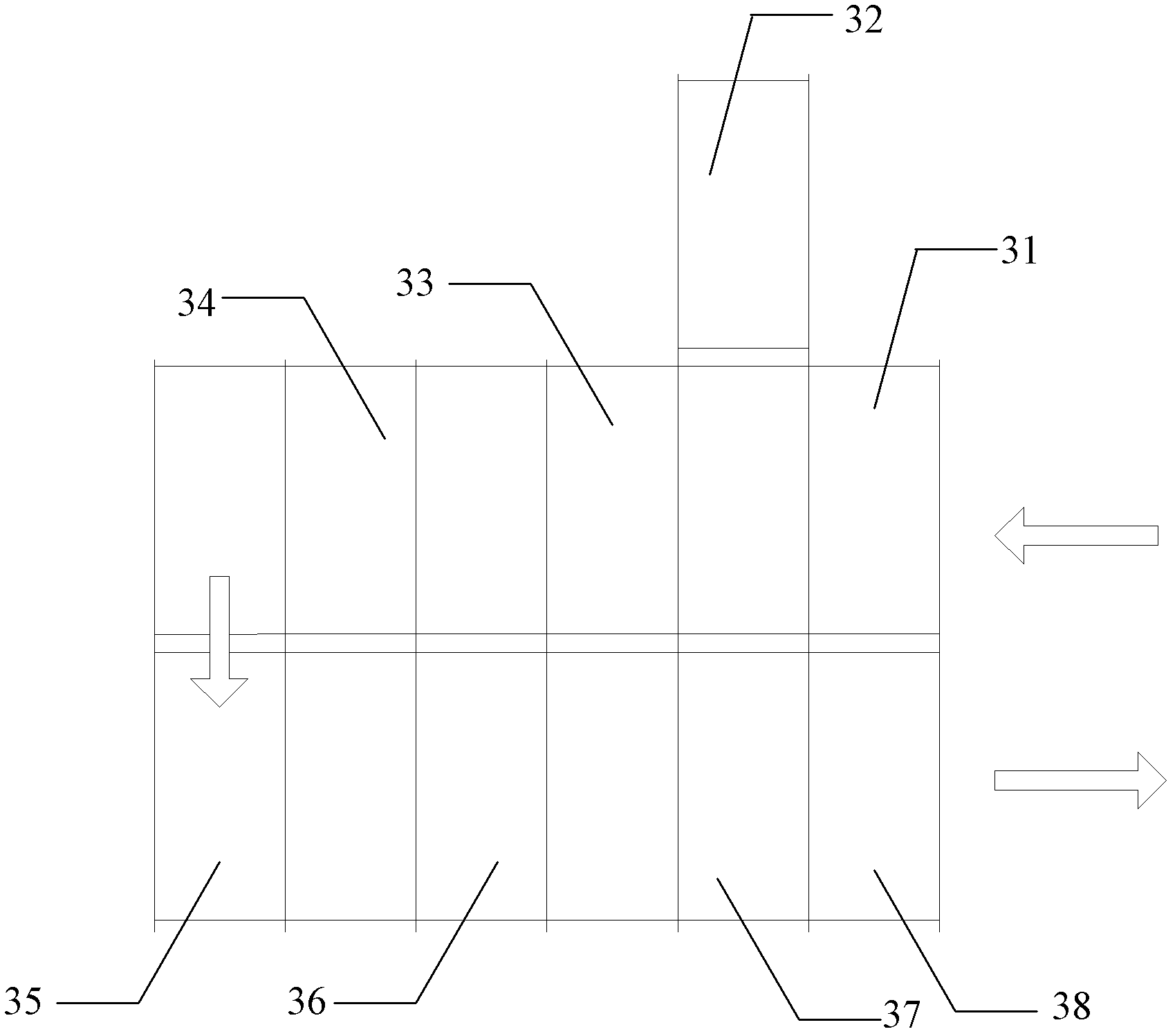

[0042] The structure of the cooling and humidity control system provided by the third embodiment of the present invention is as follows: image 3 As shown, the system includes: a return air module 31 , a fresh air module 32 , a spray module 33 , a filter module 34 , a filter module 35 , a dehumidification module 36 , a dehumidification module 37 and an air supply module 38 . The air outlet of the return air module 31 is connected to the air inlet of the spray module 33 through the ventilation duct, the air outlet of the spray module 33 is connected to the air inlet of the filter module 34 through the ventilation duct, and the air outlet of the filter module 34 is connected to the filter module 35 through the ventilation duct. The air inlet of the filter module 35 is connected with the air inlet of the dehumidification module 36 through the ventilation duct, the air outlet of the dehumidification module 36 is connected with the air inlet of the dehumidification module 37, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com