Spring operating mechanism

A technology of operating mechanism and opening spring, which is applied in the direction of contact driving mechanism, contact operating mechanism, power device inside the switch, etc., which can solve the problem of increasing the space occupied by the spring operating mechanism, damage to the moving contact, and increasing the number of products Production cost and other issues, to achieve the effect of low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

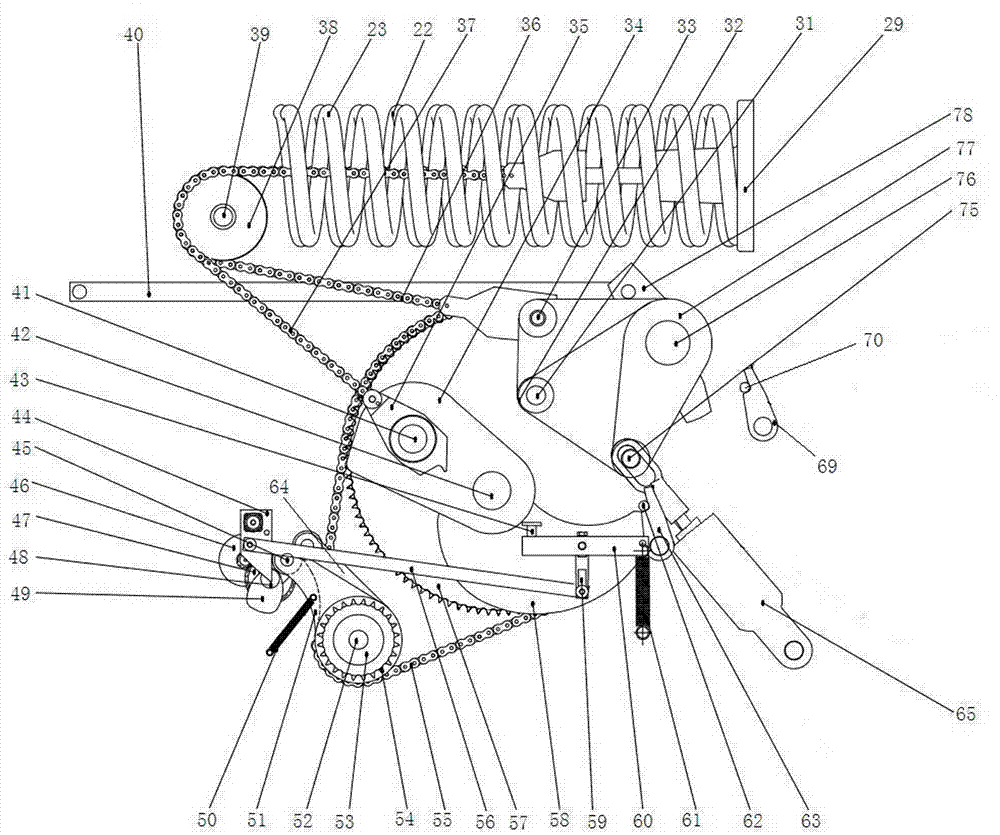

[0028] Examples of spring-operated mechanisms are Figure 1~11 Shown: including the frame, the frame includes the opening spring barrel 79, the closing spring barrel 86 and the left mounting plate 81 and the right mounting plate 80 whose lower ends are connected together by connectors, the opening spring barrel 79, the closing spring barrel 86 are side by side integrally casted, the opening spring barrel 79 and the closing spring barrel 86 are horizontally arranged, and the left and right mounting plates are also integrally cast and formed respectively, the opening spring barrel, the closing spring barrel and the left and right mounting plates are all The cast aluminum parts, the opening spring barrel and the closing spring barrel are respectively fixedly connected to the left mounting plate and the right mounting plate through a fixing structure, and the fixing structure is a bolt connection structure. The fixed structure includes a spring barrel connecting plate integrally a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com