Coil structure for rotary electric machine

A technology for rotating electrical machines and coils, applied in the shape/style/structure of winding conductors, etc., can solve problems such as miniaturization of difficult-to-rotate electrical machines, and achieve the effects of shortening length, reducing manufacturing man-hours, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

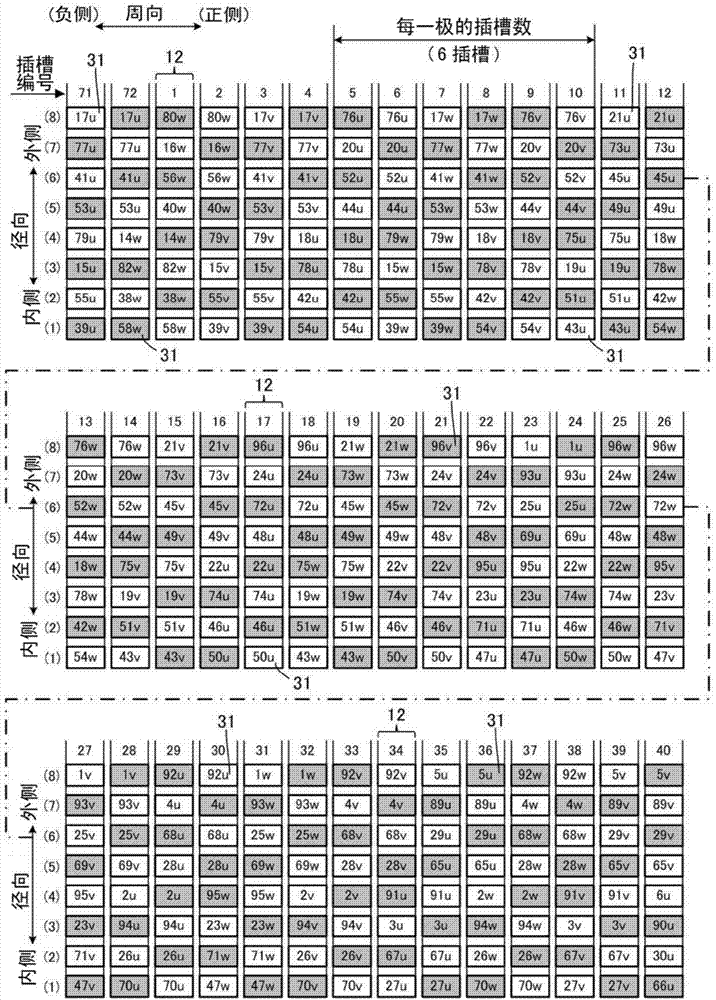

[0067] refer to Figure 1 to Figure 11 , an embodiment of the present invention will be described.

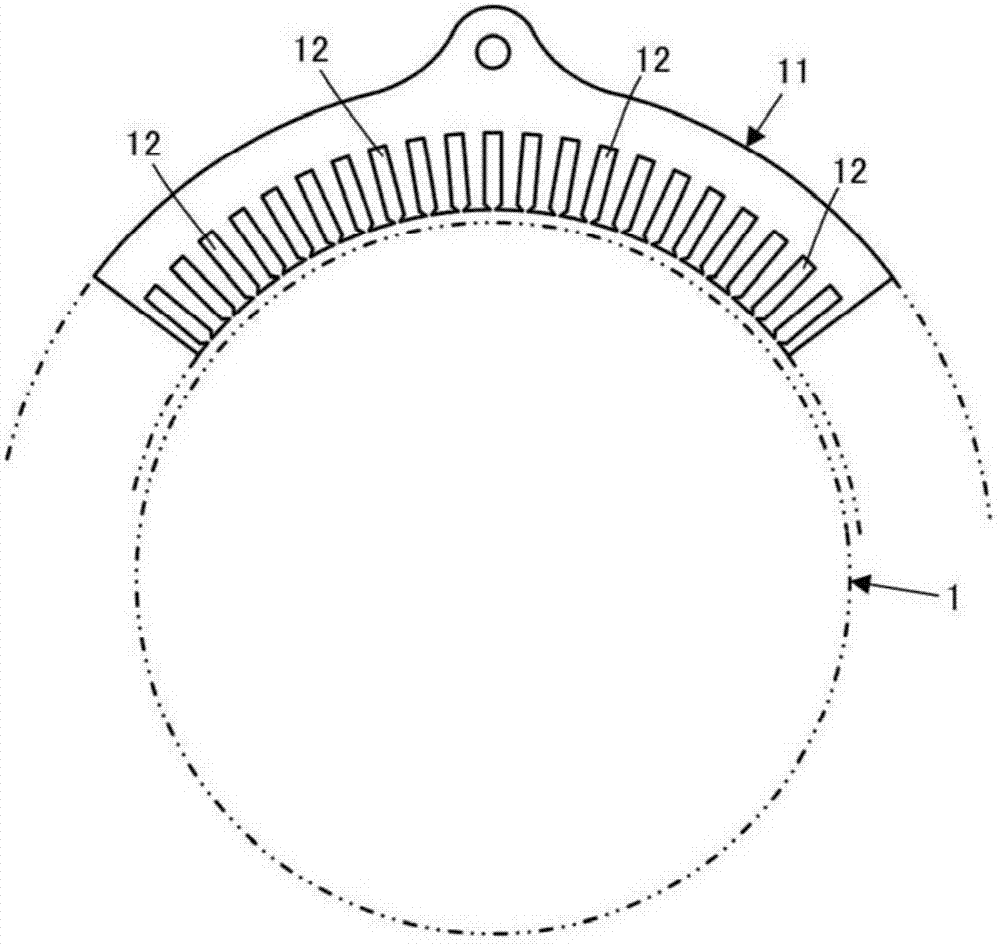

[0068] The rotating electrical machine of this embodiment includes: a substantially cylindrical stator 11 arranged around a rotor 1 ; and a magnetic flux generating coil 21 attached to the stator 11 .

[0069] Such as figure 1 As shown, a plurality of slots 12 are formed on the stator 11 along the circumferential direction of the stator 11 (direction around the axis of the stator 11 ) at regular intervals. Each slot 12 is provided so as to penetrate the stator 11 in its axial direction.

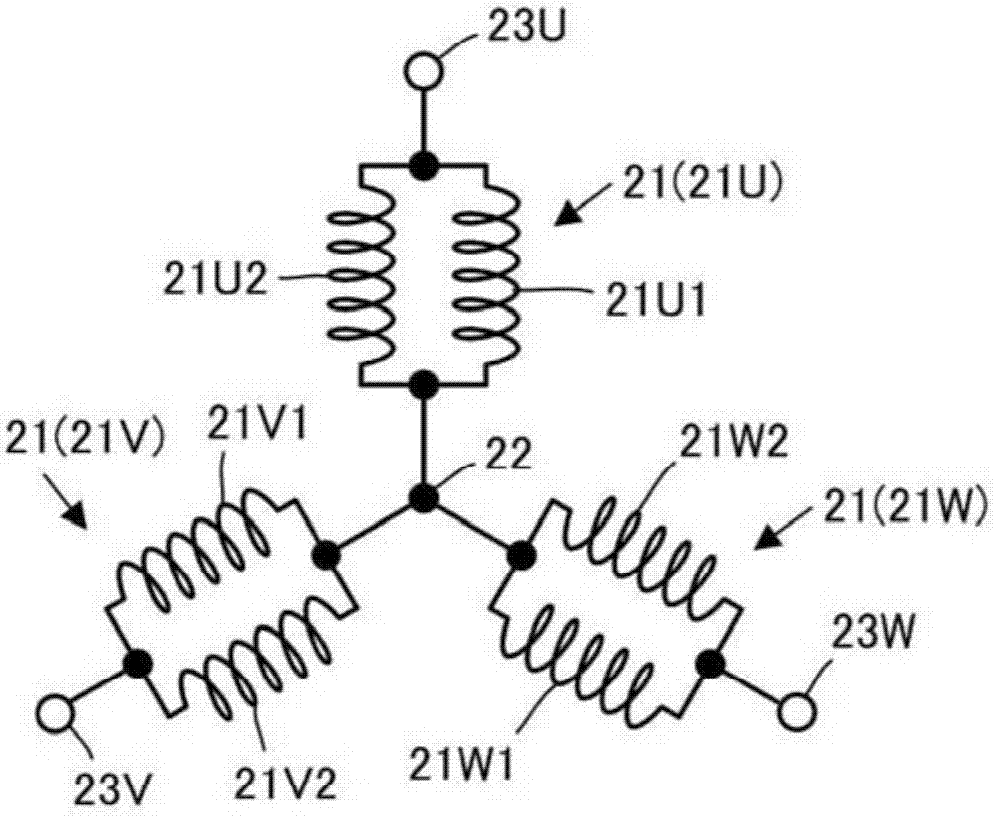

[0070] Such as figure 2 As shown, the coil 21 is constituted by three-phase coils of a U-phase coil 21U, a V-phase coil 21V, and a W-phase coil 21W. In this embodiment, the coils 21U, 21V, and 21W of the respective phases are configured by connecting two coils ( 21U1 , 21U2 ), ( 21V1 , 21V2 ), and ( 21W1 , 21W2 ) in parallel. In addition, one ends of the U-phase, V-phase, and W-phase coi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com