Electronic module and method for manufacturing same

An electronic module and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as miniaturization of electronic modules that are difficult to adjust the heat sink

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

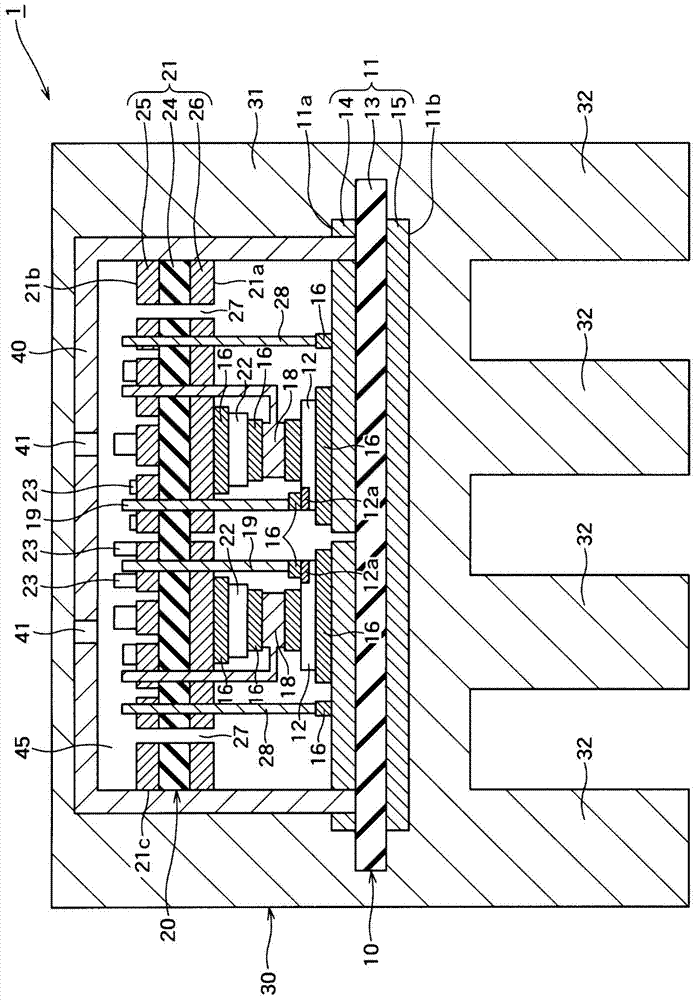

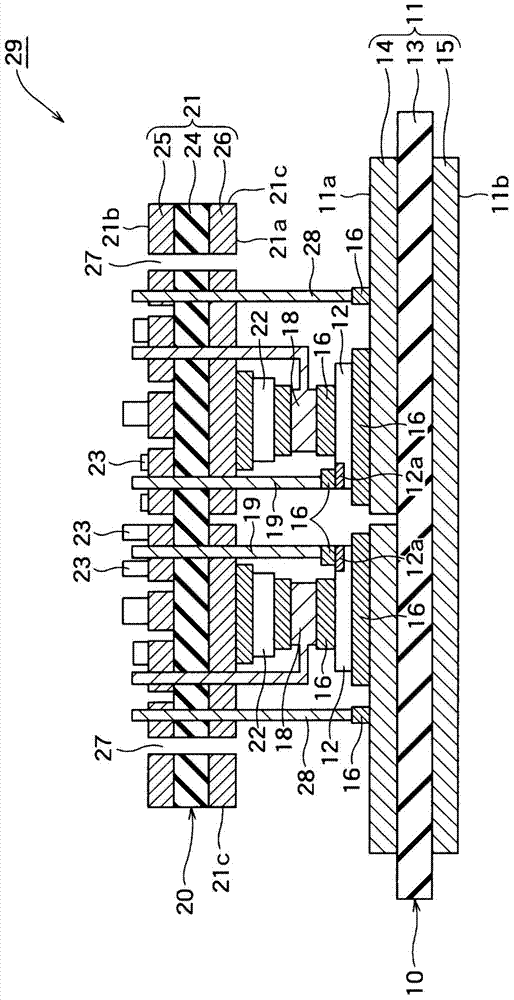

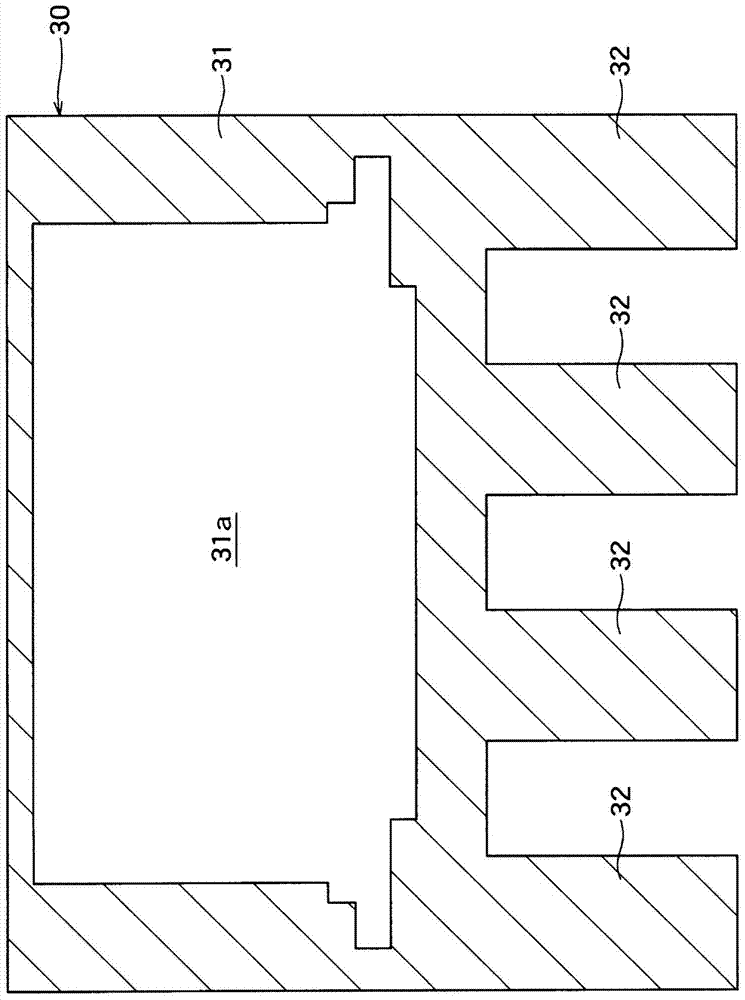

[0034] For Embodiment 1 of the present invention, refer to Figure 1 to Figure 3 Be explained. figure 1 It is a cross-sectional view of the electronic module 1 according to the first embodiment. figure 2 It is a cross-sectional view of a laminated module 29 in which two electronic modules 10 and 20 are laminated. image 3 It is a sectional view of the heat sink 30 provided with the accommodating part 31a concerning Embodiment 1. As shown in FIG.

[0035] The electronic module 1 according to Embodiment 1 includes an electronic module 10 , an electronic module 20 stacked on the electronic module 10 , and a heat sink 30 that accommodates the electronic module 10 and the electronic module 20 therein.

[0036] Such as figure 2As shown, the electronic module 10 and the electronic module 20 are laminated to form a laminated module 29 . The planar size of the substrate 21 is smaller than that of the substrate 11 . In addition, when the laminated module 29 is viewed in the thic...

Embodiment approach 2

[0075] For the second embodiment of the present invention, refer to Figure 5 Be explained. Figure 5 It is a cross-sectional view of the electronic module 1A according to the second embodiment. One of the differences between Embodiment 2 and Embodiment 1 lies in the structure of the cover. Hereinafter, Embodiment 2 will be described around this difference.

[0076] Such as Figure 5 As shown, in Embodiment 2, the cover portion 40A covers the main surface 21 b of the substrate 21 , and the space between the substrate 11 and the substrate 21 is not covered by the cover portion 40A. In addition, the outer surface of the lid portion 40A is in contact with the inner wall surface of the housing portion 31 a of the heat sink 30 .

[0077] In addition, the lid portion 40A is desirably made of a metal whose surface is insulated (for example, aluminum anodized aluminum), but may be made of an insulator.

[0078] Such as Figure 5 As shown, in the cover part 40A, the resin injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com