Energy-saving and environment-friendly process technical equipment for efficient scrap steel hopper filling and close-range dust collection

An energy-saving, environmental-friendly, technological technology, applied in the direction of dust removal, cleaning methods using gas flow, cleaning methods and appliances, etc., can solve the problems of high energy consumption and environmental pollution in the scrap steel production process, achieve optimal dust removal, and reduce driving The effect of running power consumption and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

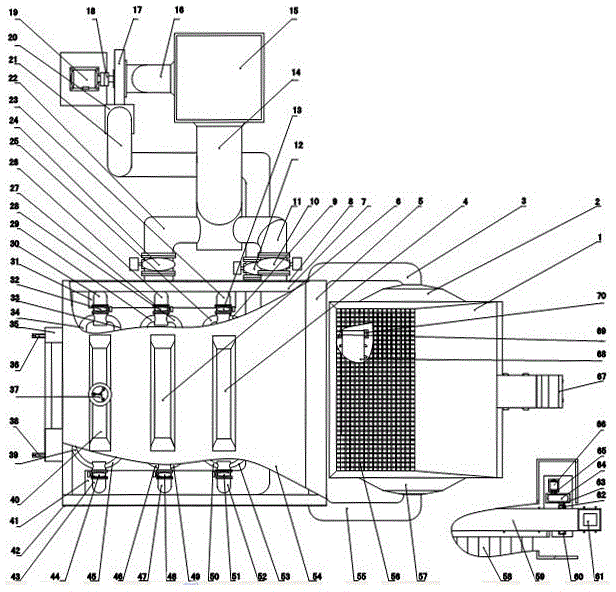

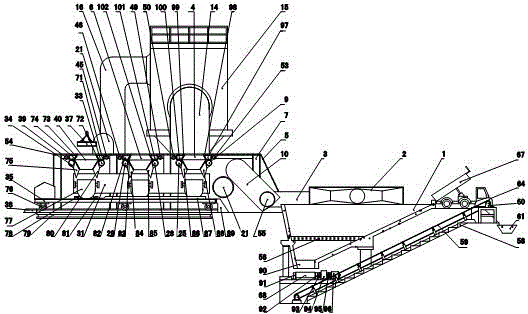

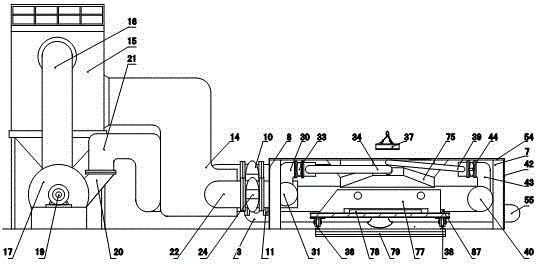

[0030] Such as figure 1 , 2 , 3, according to the function is divided into four parts:

[0031] The first part: scrap steel discharge dust collection treatment area, which includes: scrap steel discharge chute (1), the middle and lower part of the scrap steel discharge chute (1) is equipped with a screen (56), the middle bottom of the scrap steel discharge chute (1) A dust leakage port (90) is provided, and a flat conveyor belt (68) is installed below the dust leakage port (90), and the inner end of the flat conveyor belt (68) is respectively connected with a bearing seat (69) on one side of the inner end, The bearing seat (70) on the other side of the inner end, one side of the outer end of the flat conveyor belt (68) is connected to the bearing seat (91) on the outer end side, and the other side is connected to the bearing seat (92) on the other side of the outer end. The side bearing housing (92) is connected to the flat low-speed adapter (93), the flat low-speed adapter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com