Remediation method of organic contaminated soil

A technology of organic pollution and remediation method, which is applied in the field of soil remediation, can solve the problems of high cost and low heat utilization rate, and achieve the effects of fast heating efficiency, increased residence time and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

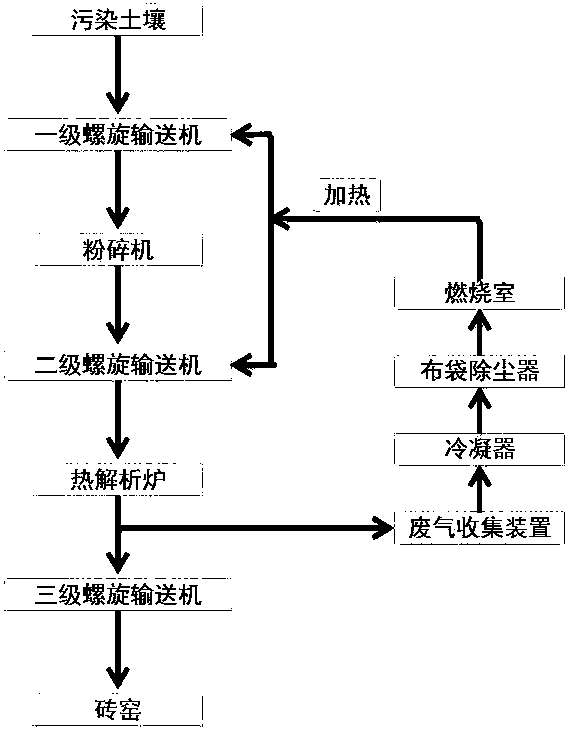

Image

Examples

Embodiment 1

[0029] The benzopyrene-contaminated soil with a pollution concentration of 200mg / kg has a moisture content of 20%. After passing through the first-stage screw conveyor, the pollutant removal rate is about 5%. After passing through the second-stage conveyor, the pollutant removal rate is 10%. %, the pollutants enter the thermal desorption furnace for heating for 20 minutes, the soil temperature is about 250-300°C, the pollutant removal concentration is 85%, and the soil temperature reaching the brick kiln through the third pole conveyor is 175°C. After the final brick is made, no contaminants can be detected. The heat generated in the thermal desorption process is effectively used, the cost of soil remediation is reduced, and the problem of polluted soil is effectively removed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com