Car crankshaft connecting rod

A crankshaft connecting rod and special machine technology, which is applied to turning equipment, turning equipment, metal processing machinery parts, etc., can solve the problems of slow production efficiency, high cost, expensive machine tool equipment, etc., and achieve burden reduction, low cost, and fast processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

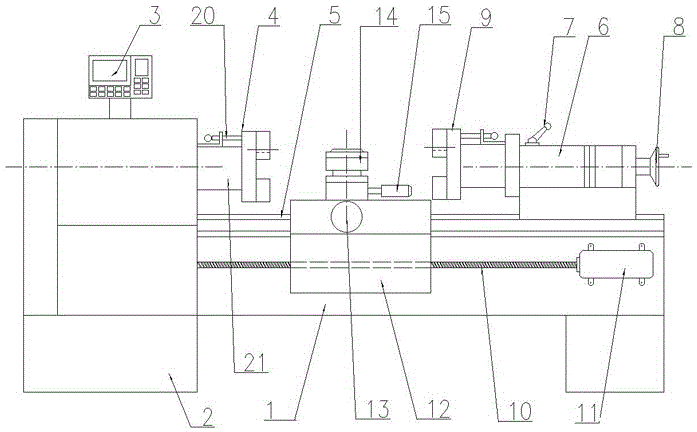

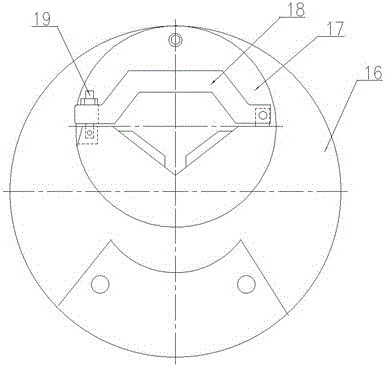

[0009] like figure 1 , a special machine for crankshaft connecting rod, which includes body 1, gear box 2, control display screen 3, main eccentric disc 4, slideway 5, tailstock 6, tailstock locking handle 7, feed handle 8, tail eccentric disc 9 , screw mandrel 10, servo motor 11, flow plate box 12, transverse feed motor 13, rotary cutter head 14, cutter head rotating motor 15, vehicle body 1 is connected with gear box 2, control display screen 3 is fixed on the gear box 2, The main eccentric disc 4 is connected with the gear shaft in the gearbox 2, the body 1 is provided with a slideway 5, the tailstock 6 rides on the slideway 5 of the body 1, the tail eccentric disc 9 is fixed on the tailstock 6, and the main eccentric The disc 4 has the same structure as the tail eccentric disc 9, the feed handle 8 is connected with the tail stock 6, the tail stock locking handle 7 is fixed on the tail stock 6, the servo motor 11 is fixed on the body 1 and connected with the gearbox 2 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com