Electric drill capable of adjusting diameter of drill bit and use method of electric drill

A drill diameter and electric drill technology, which is applied in drilling/drilling equipment, parts of boring machine/drilling machine, drill repairing, etc., can solve problems such as the inconvenience of carrying multiple drill bits and the trouble of replacing drill bits, so as to achieve easy processing and implementation, and improve operation Effects of improving safety and component utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

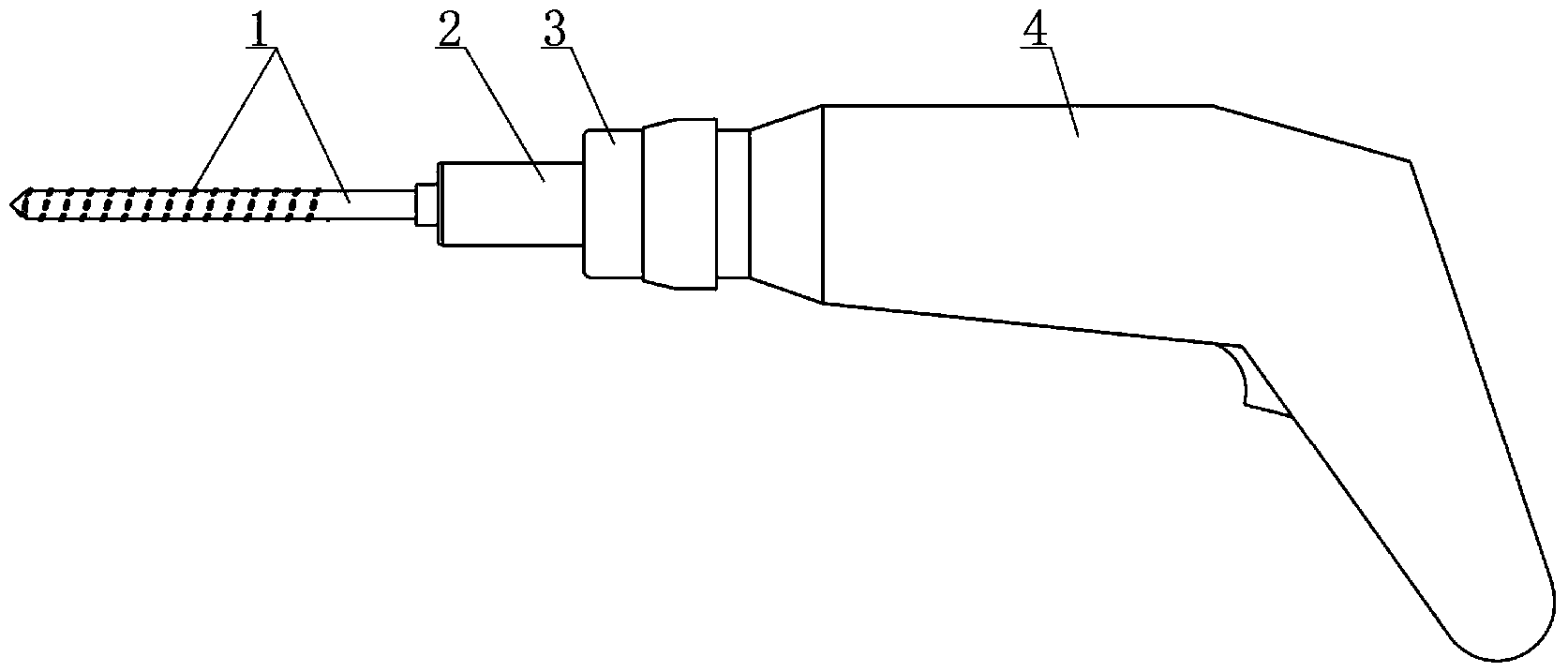

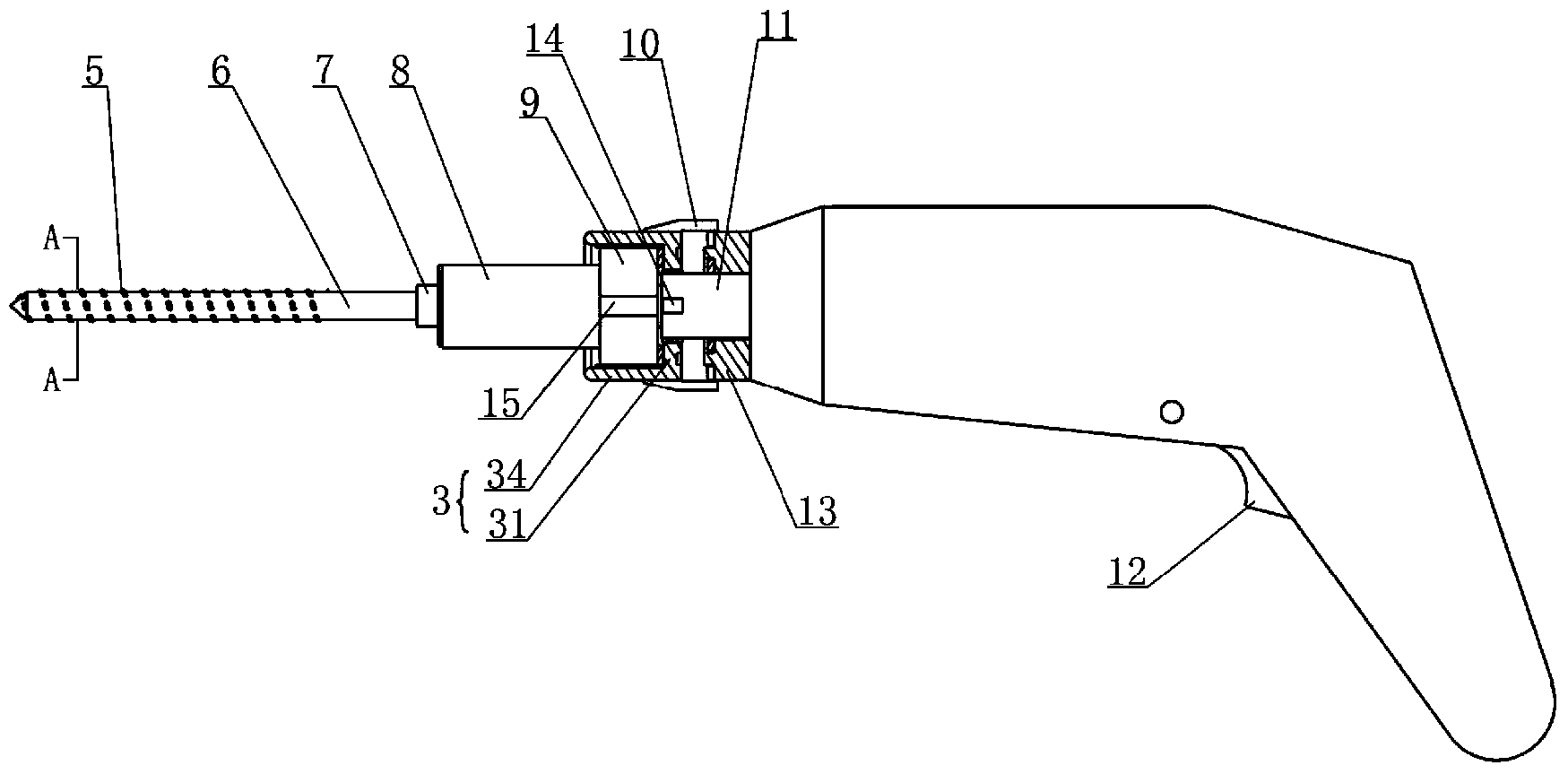

[0033] see figure 1 As shown, the present invention discloses an electric drill with an adjustable drill bit diameter, which is composed of a body assembly 4 , a clutch sliding sleeve 3 , a hydraulic adjustment assembly 2 and an expandable drill bit 1 .

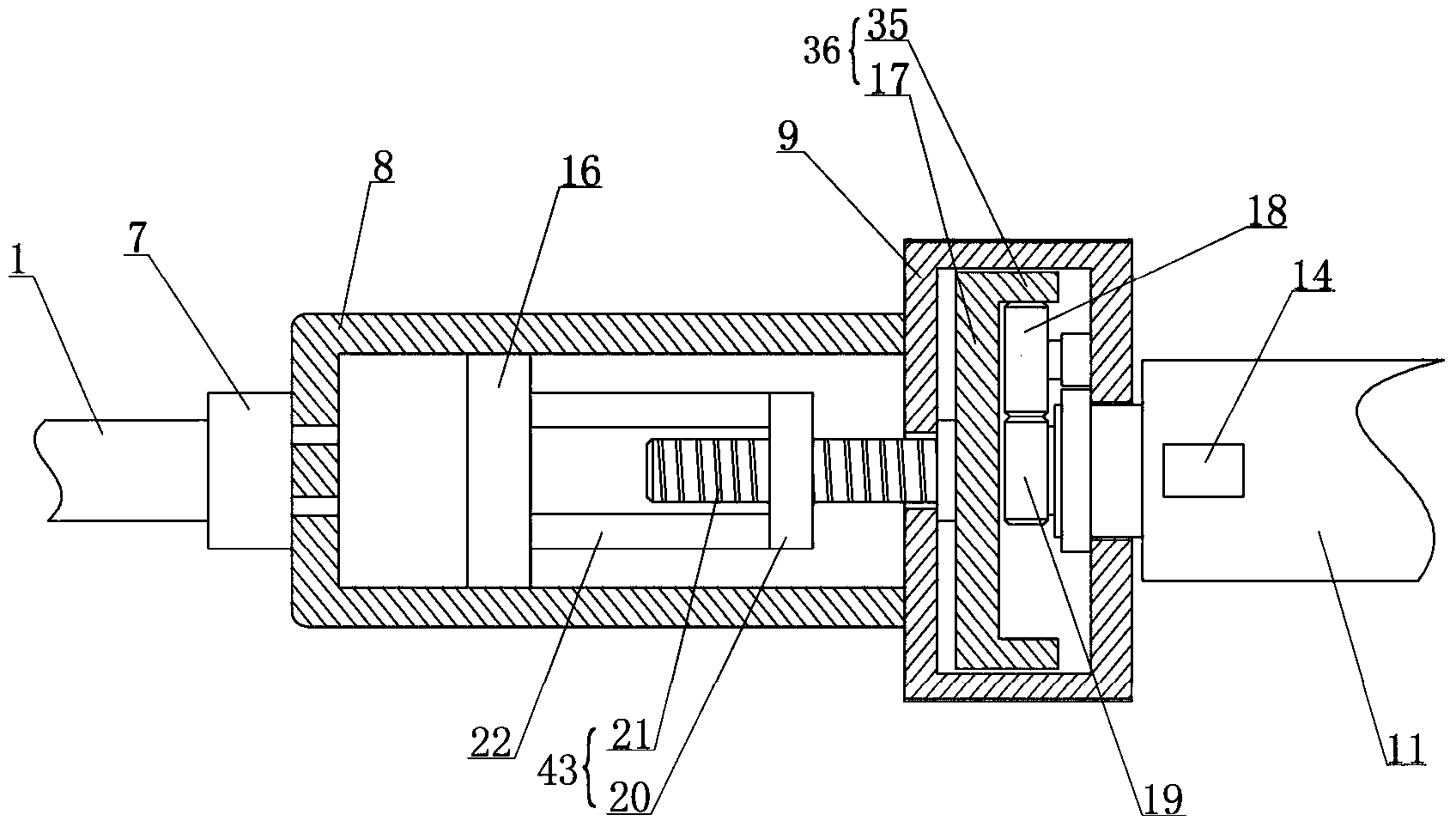

[0034] see figure 1 , 2 As shown, the body assembly 4 is provided with a power supply part, a motor part, and a deceleration part in the housing, and its internal structure is the same as that of existing similar products. The front end of the body assembly 4 housing is provided with an output shaft 11 and The fixed shaft sleeve 13 coaxial with the output shaft 11, the fixed shaft sleeve 13 and the housing are relatively fixed, the two can adopt an integrated structure, the body assembly 4 is provided with a switch 12, and the output shaft 11 can be controlled by the switch 12. reverse or stop.

[0035] See attached figure 2 , 3As shown, the hydraulic adjustment assembly 2 includes a hydraulic cylinder 8 and a decelerat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com