A synchronizer gear sleeve deburring machine and its use method

A deburring machine and synchronizer technology, applied in the field of synchronizer processing, can solve the problems of burr hypertrophy, affecting the roughness of the tooth surface, not considering burrs, etc., achieving fast pressing and loosening, improving assembly qualification rate, and burr removal. thorough effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention is described in further detail:

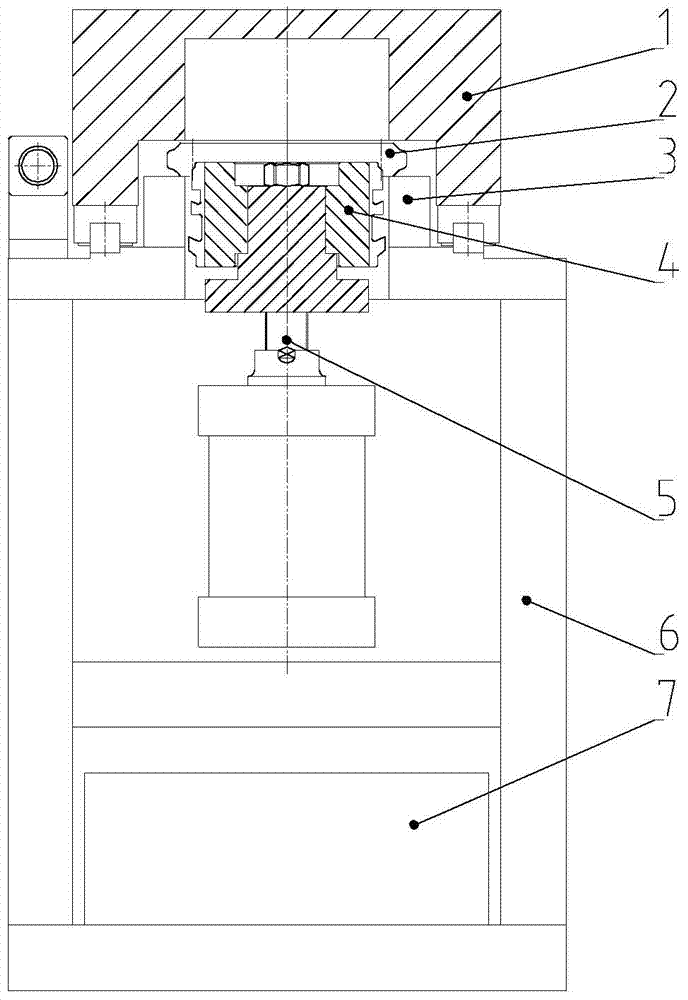

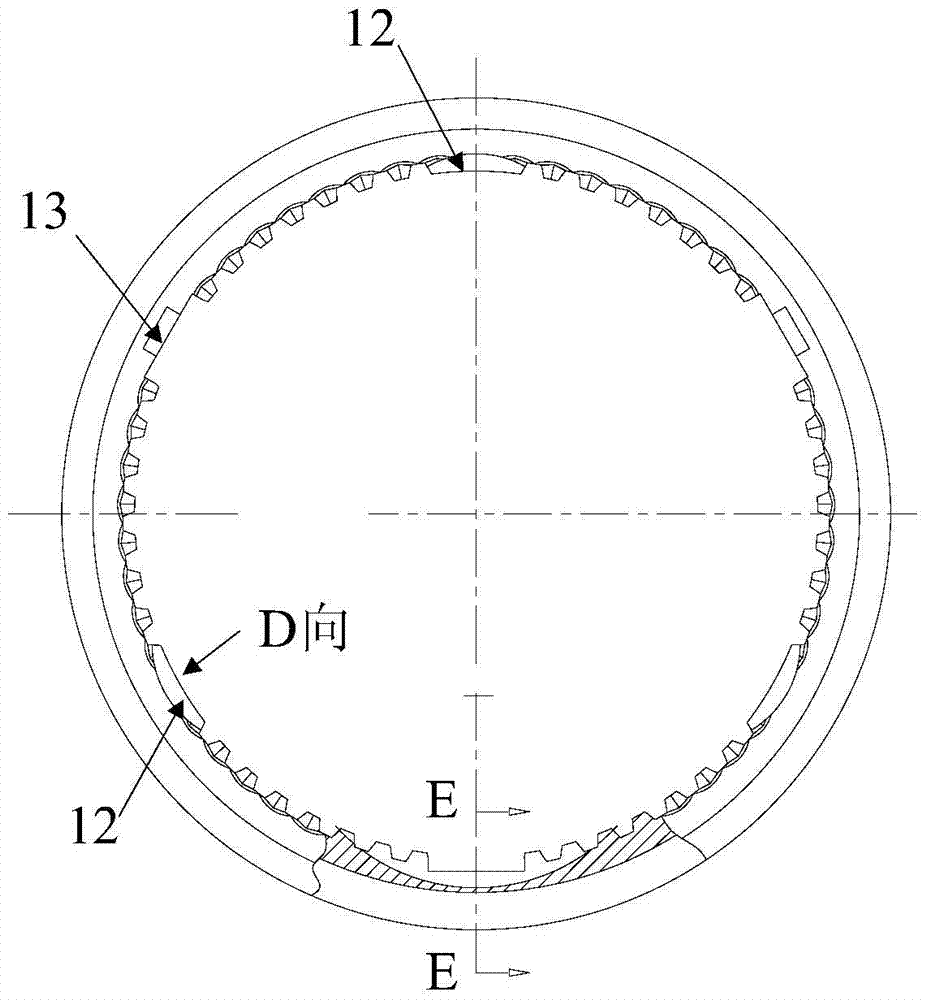

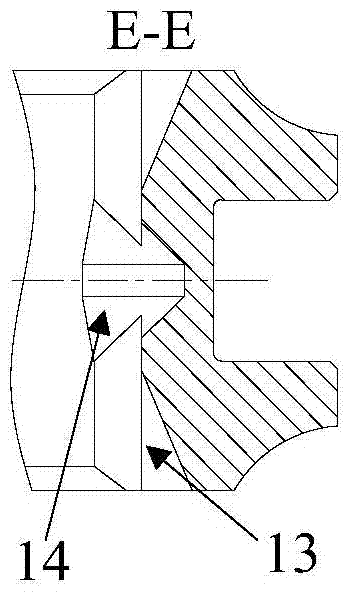

[0037] refer to figure 1 , the present invention comprises machine tool body 6, and the cooling box 7 that has cutting fluid, hydraulic cylinder 5, knife shim, push knife 4, workpiece 2 and horizontal slide plate 1 are installed successively in machine tool body 6 from bottom to top, wherein push knife 4 It is cylindrical, and the workpiece 2 is circular and has an internal spline structure; the push knife 4 is provided with an I-shaped through hole connecting the piston rod of the hydraulic cylinder 5 along the axial direction, and the push knife 4 and the hydraulic cylinder 5 are provided. Knife pad, push knife 4 is equipped with supporting part 3, which is used to position and support workpiece 2; workpiece 2 is partly sleeved on push knife 4; slide plate 1 is installed on machine tool body 6 horizontally through guide rail, and slide plate 1 can be horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com