A traction device that guides copper tubes through the fins of the condenser

A traction device and condenser technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems that it is difficult to ensure that the copper pipes pass through sequentially, mass production cannot be realized, and the guiding process is prone to deviation. Achieve the effects of reducing product scrap rate and labor costs, accurate insertion, and avoiding collision deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

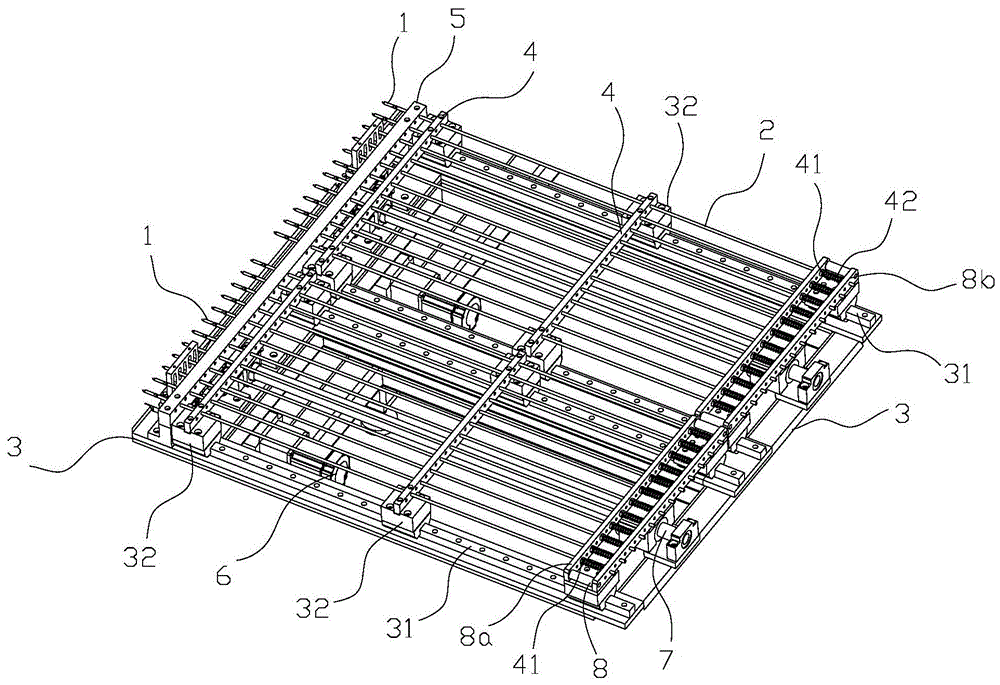

[0030] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

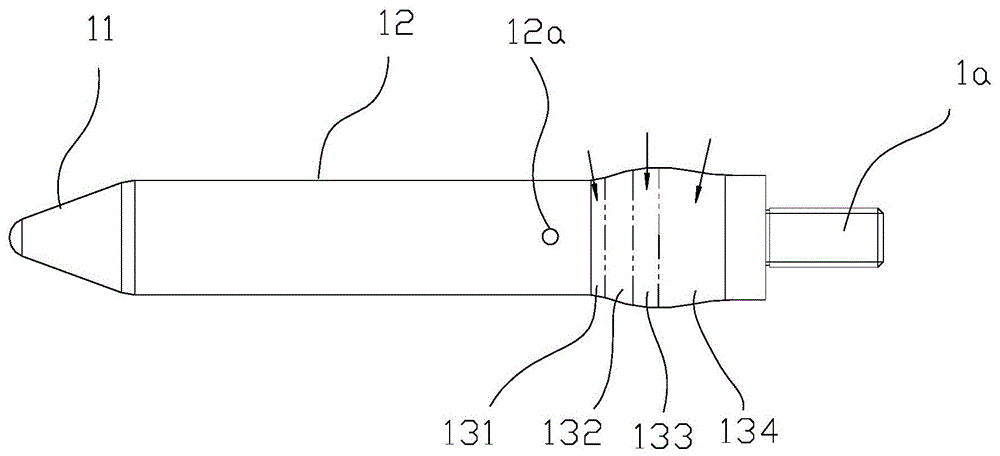

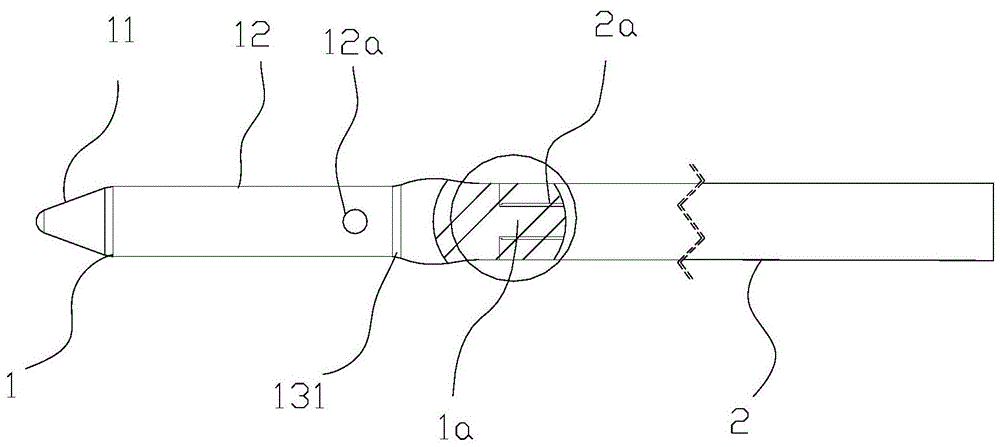

[0031] Refer to attached figure 1 To attach figure 2 As shown, a draw rod for guiding copper tubes through the fins of the condenser includes a detachably connected draw head 1 and a rod body 2, and the end of the draw head 1 is provided with a convex buckle 1a extending along its length direction, so The front end of the rod body 2 is provided with a groove 2a that engages with the convex buckle 1, and the convex buckle 1a is spirally connected with the groove 2a. The pulling head is provided with a jack 12a that can be inserted into a screwdriver. Through the jack 12a Install and connect or disassemble the traction head and rod body. The front end of the pulling head 1 is a pointed insertion part 11, the middle end is a linear holding part 12, the rear end includes a shielding part 132 protruding upwards from front to back, and a shield...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com