Image inkjet printing method and device

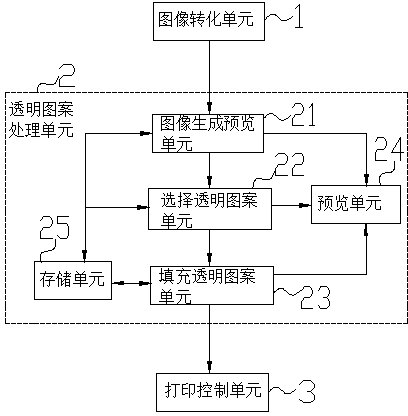

An image and inkjet technology, which is applied in printing and other directions, can solve the problems of lack of vividness and layering, and the printing effect is not intuitive enough, and achieve the effect of wide application range, perfect function and enhanced operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

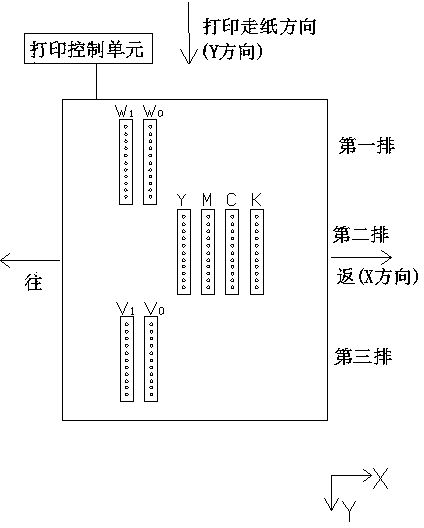

Method used

Image

Examples

Embodiment 1

[0045] Figure 4 It is a schematic diagram of adding the first transparent pattern on the image to be printed, and the size of the image to be printed is an integer multiple of the size of the transparent pattern. Define the length direction dimension of the image to be printed as D, the width direction dimension as Y, define the length direction dimension of the transparent pattern as d, and define the width direction dimension as y, then D / d=N, N is a positive integer; Y / y=M, M is a positive integer. After the user chooses to add the first transparent pattern, fill the transparent pattern unit 23 to arrange the first transparent pattern in the first row from left to right, and when the first row is arranged to the rightmost boundary position of the color image to be printed, start from left to right. Arrange the second row from the right, when the second row reaches the rightmost position of the color image to be printed, start to arrange the third row from left to right, ...

Embodiment 2

[0048] Also define the lengthwise dimension of the image to be printed as D, the widthwise dimension as Y, define the lengthwise dimension of the transparent pattern as d, and the widthwise dimension as y, when D / d=N, N is a non-integer or Y / y=M, when M is a non-integer, that is, when the size of the image to be printed is not an integer multiple of the size of the transparent image, the user first chooses to add a transparent pattern, Figure 6 It is shown that the first transparent pattern is selected, and the filling transparent pattern unit 23 splices the transparent pattern in the following manner: first arrange the first transparent pattern to the first row from left to right, and when the first row is arranged to the border of the first transparent pattern beyond the After printing the rightmost border of the image, start to arrange the second row from left to right. When the second row is arranged until the border of the first transparent pattern exceeds the rightmost ...

Embodiment 3

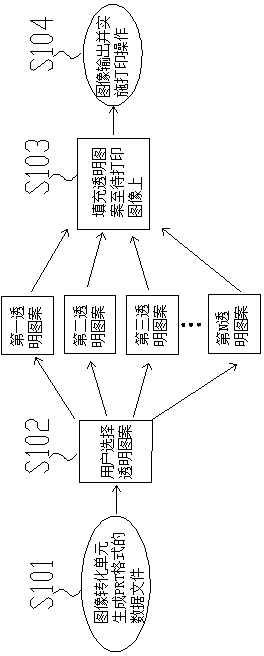

[0050] Figure 7 , 8 It is the operation flow and three-dimensional schematic diagram of the printing method of directly spraying the transparent pattern on the medium to be printed in the present invention, that is, the medium to be printed already has a color image, and only needs to print the transparent pattern on the medium to be printed to realize the surface three-dimensional touch, Effects such as layering or shine. The specific operation method is as follows: step S201, the user performs the loading operation on the printing medium. If a platform printer is used, the user first places the to-be-printed medium with a color image on the printer platform; if a roll-to-roll printer is used, the user first places the The paper roll of the medium to be printed with the image is loaded; step S202, the user selects the desired transparent pattern in the transparent pattern processing unit, and inputs the length and width of the medium to be printed; step S203, the transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com