Control arm assembly with turned edge sleeve structure and manufacturing technology for control arm assembly

A preparation process and technology for controlling arms, which are applied to the cantilever mounted on the pivot, suspension, transportation and packaging, etc. Thinning, improving connection stiffness, solving the effect of material accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

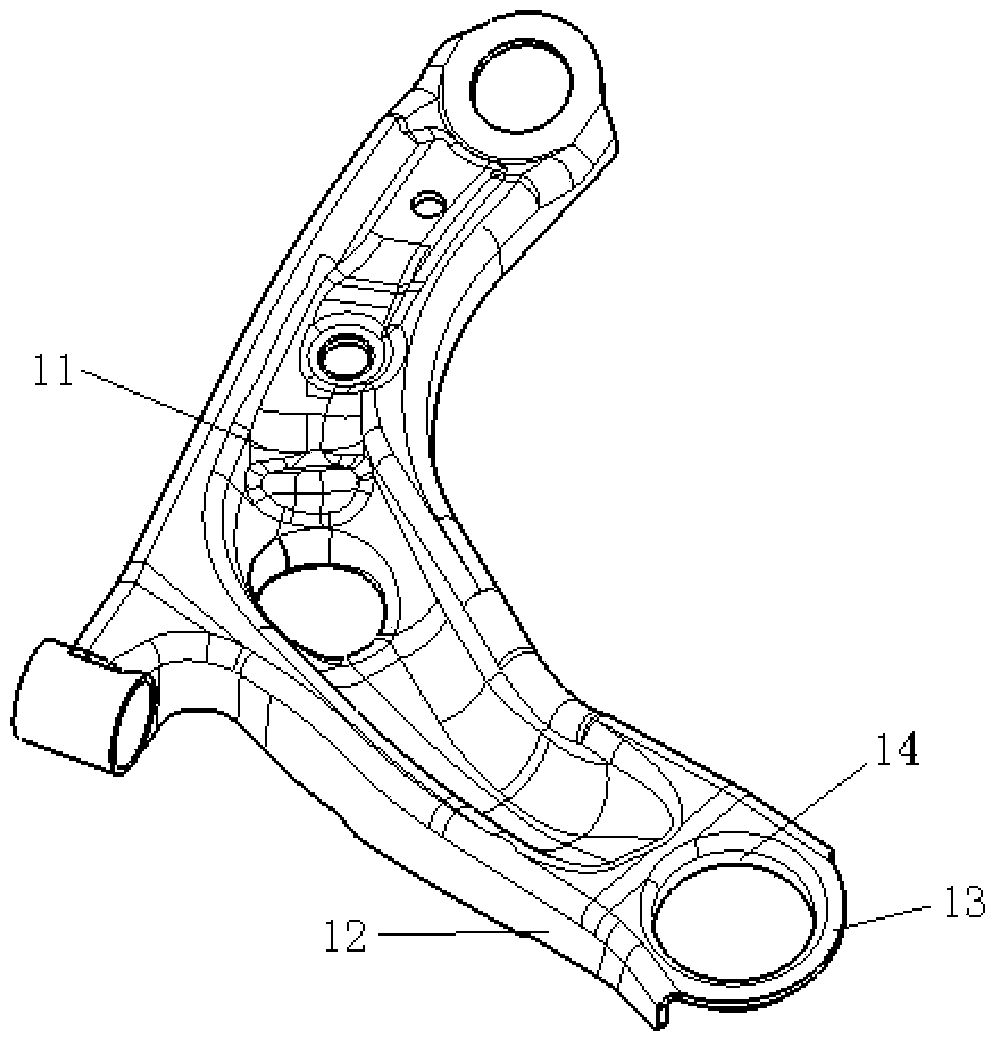

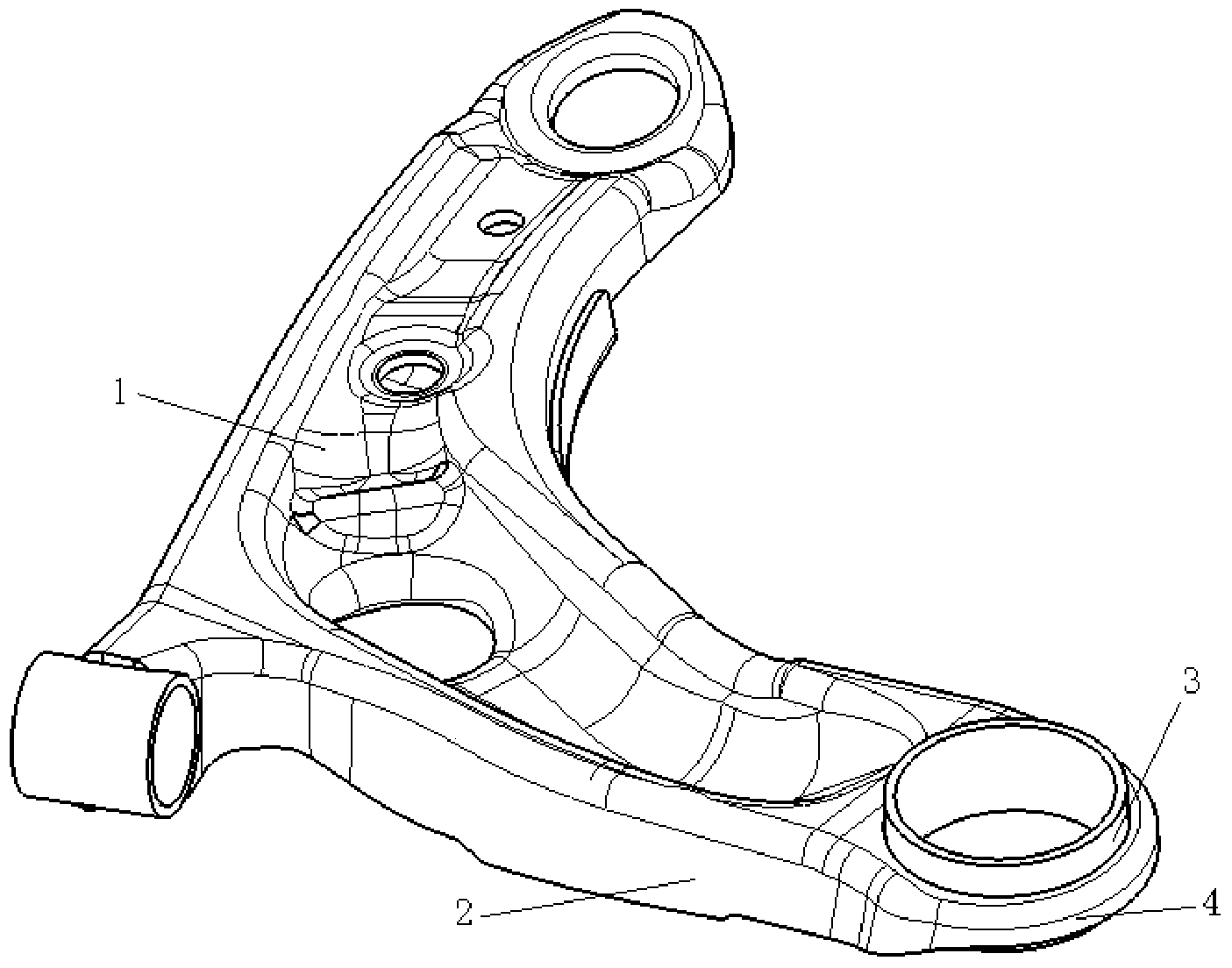

[0035] The control arm assembly in the present application refers to the front lower swing arm assembly. The main structure of the control arm assembly in the present application is not improved, but only an improvement scheme proposed for the part of the control arm assembly.

[0036] In this application, the preparation material of the control arm is an existing technology, which is selected according to different needs, and does not affect the realization of the technical solution of this application.

[0037] The control arm assembly of the present application is provided with three bushes, which are respectively located at the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com