Mining dump vehicle frame

A mining dump truck and frame technology, which is applied to vehicle components, substructure, transportation and packaging, etc., can solve problems such as cracking of weld seams and decline in the overall mechanical properties of the frame, so as to save manufacturing costs, improve bending resistance, Avoid stress concentration effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The frame of the mining dump truck is elongated as a whole, and its length direction is "longitudinal", the direction perpendicular to the longitudinal direction in the horizontal plane is "transverse", and the direction perpendicular to the longitudinal direction in the vertical plane is "vertical". ".

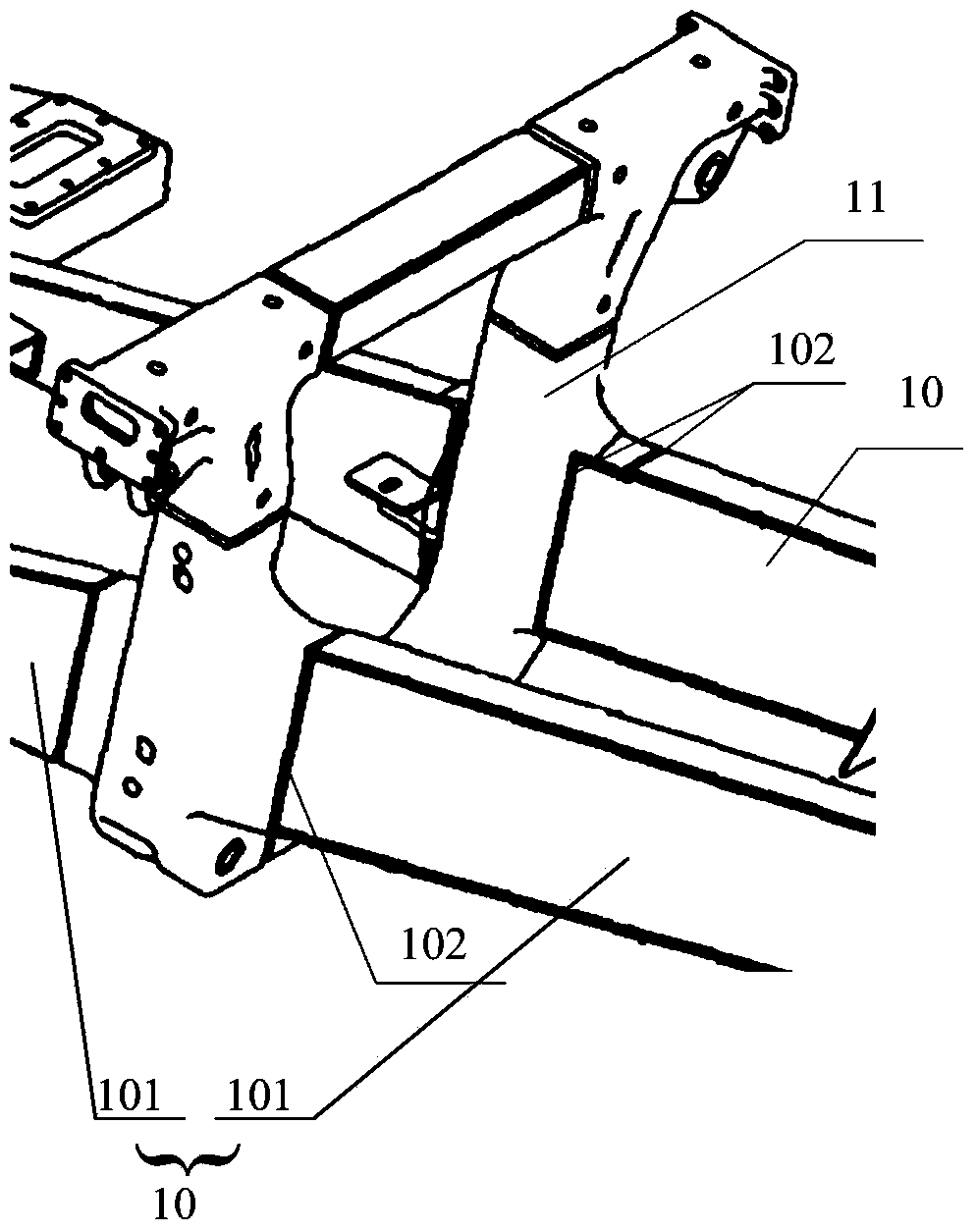

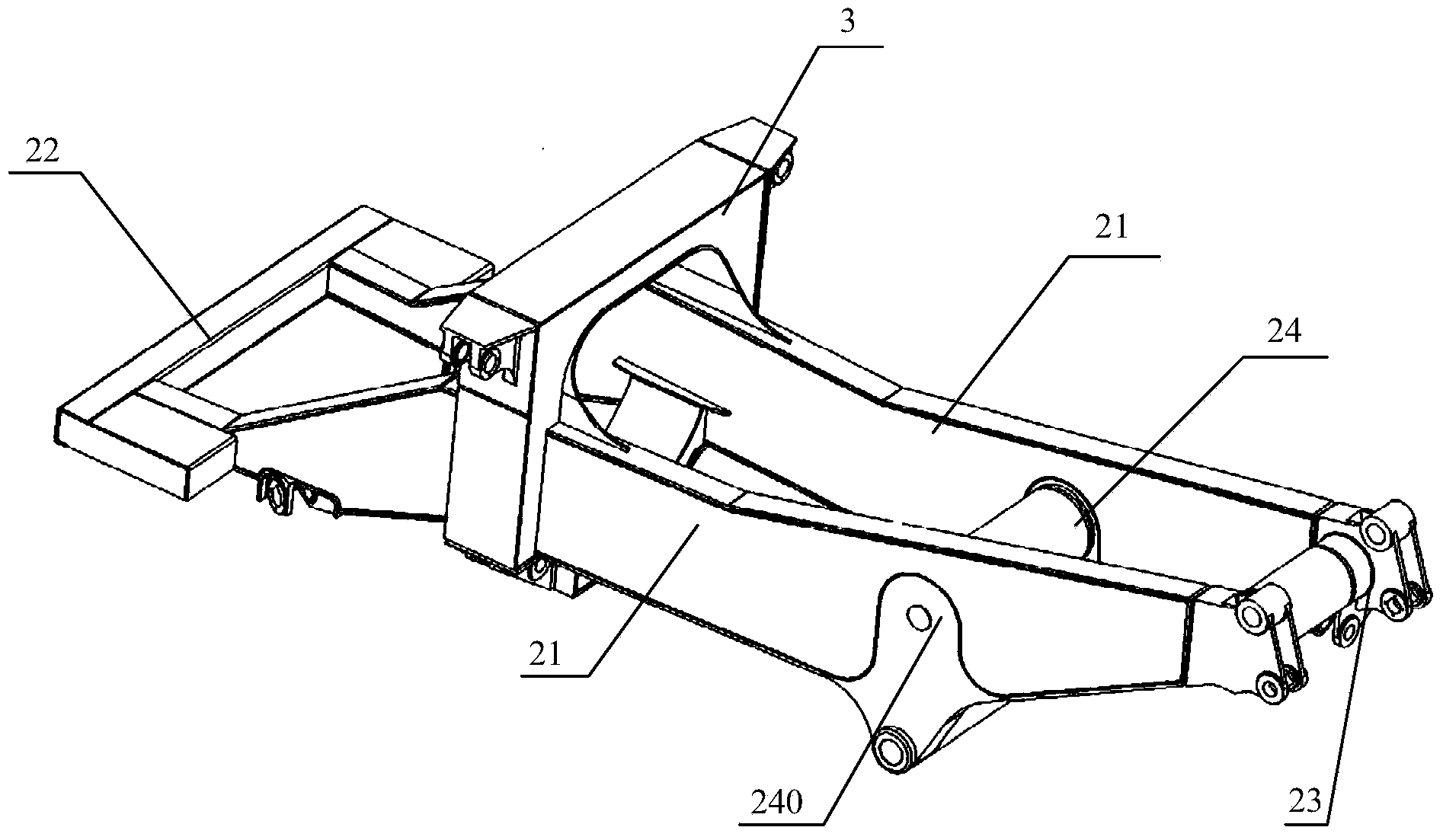

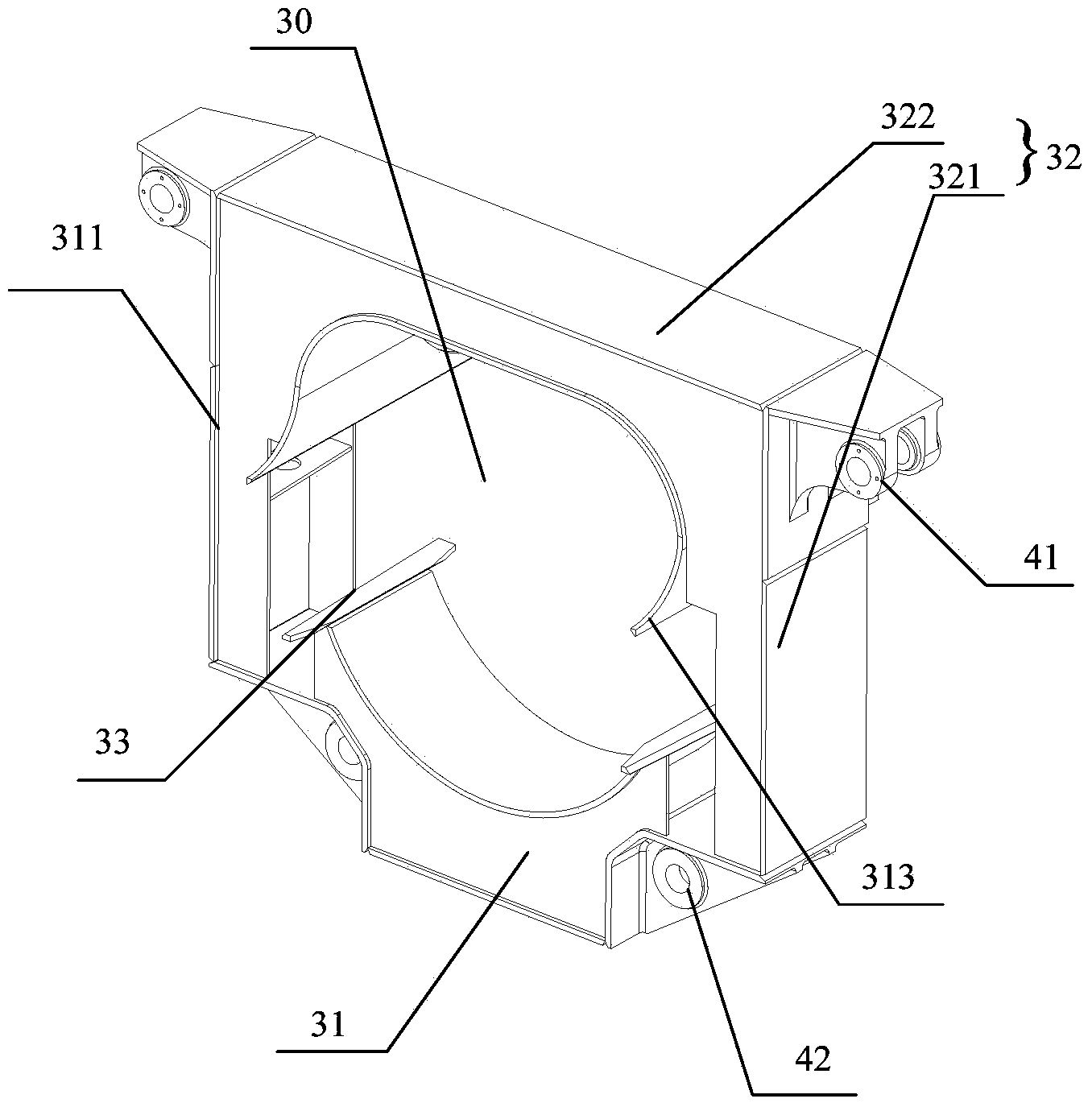

[0014] figure 2 It is a perspective view of an embodiment of the mine dump truck frame of the present invention; image 3 for figure 2 Schematic diagram of the structure of the central gantry beam; Figure 4 for image 3 Schematic diagram of the midsole beam structure; Figure 5 for image 3 Structural diagram of the roof beam; please refer to Figure 2-5 , this embodiment provides a mining dump truck frame, including two longitudinal beams 21, the two longitudinal beams 21 are not parallel to each other and symmetrical about the longitudinal axis of symmetry; the head ends of the two longitudinal beams 21 are fixedly connected by the front end beam 22 , a tai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap