A special hoisting tool for blowout preventer

A technology for lifting tools and blowout preventers, which is applied in the field of special lifting tools for blowout preventers, can solve problems such as undiscovered, and achieve the effects of improving stability, strengthening fixed structures, and stabilizing the structure of lifting tools.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

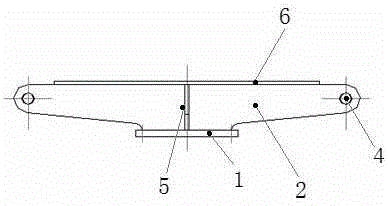

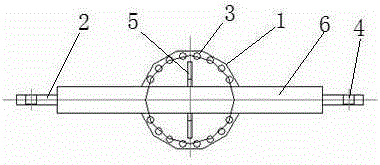

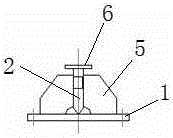

[0027] Such as figure 1 , figure 2 and image 3 As shown, the present invention discloses a special hoisting tool for blowout preventer, including a flange 1 connected with the blowout preventer and a lifting plate 2 connected with lifting equipment;

[0028] The flange 1 is compatible with the upper flange port of the blowout preventer. There are several threaded holes 3 evenly distributed on the flange 1 to connect and fix the upper flange port of the blowout preventer. Through the threaded holes 3, the flange 1 It is fixedly connected with the upper flange port of the blowout preventer;

[0029] The lifting plate 2 is an isosceles trapezoidal ear plate whose upper bottom length is greater than that of the lower bottom. Both ends are provided with a circular lifting hole 4, and the lifting plate 2 is fixedly connected with the lifting equipment through the circular lifting hole 4 as a lifting point.

[0030] In this example,

[0031] one. In order to improve the stab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com