Support for polycrystalline cast ingot feeding vehicle

A technology of polycrystalline ingot casting and feeding carts, which is applied in the direction of polycrystalline material growth, crystal growth, lifting devices, etc., can solve problems such as not being able to meet the load requirements of G6, and achieve the effect of increasing the amount of feeding and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

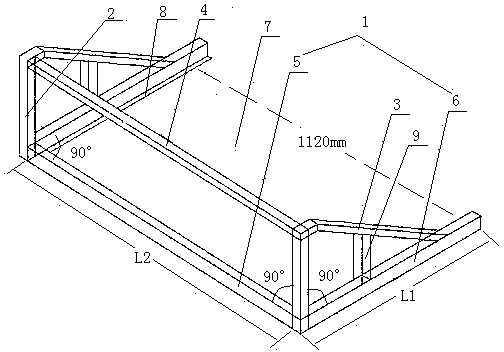

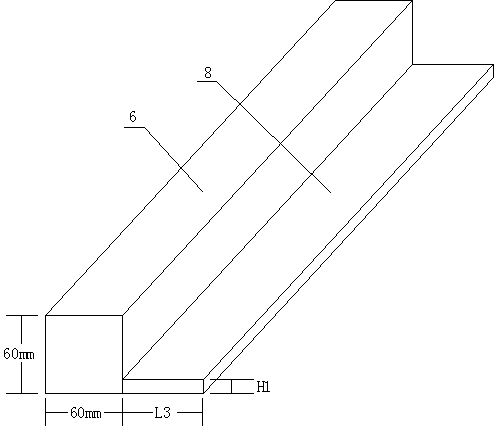

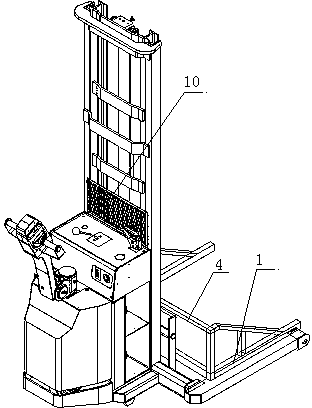

[0011] As shown in the figure, a bracket for a polycrystalline ingot feeding truck includes a base 1, a support frame 2, a connecting rod 3 and a beam 4, and the base 1 consists of a horizontal base frame 5 and two vertical base frames 6 is welded together, the vertical base frame 6 is vertically fixed at both ends of the horizontal base frame 5, and the horizontal base frame 5 and the vertical base frame 6 wrap around to form a loading area 7, and the loading area 7 The length and width are both 1120mm, the length L1 of the vertical base frame 6 is 1610mm, the length L2 of the horizontal base frame 5 is 1120mm, the vertical base frame 6 and the horizontal base frame 5 are both square steel pipes with a section of 60mm*60mm, The inner side of the vertical base frame 6 is provided with a material carrying beam 8, the width L3 of the material carrying beam 8 is 30mm, the thickness H1 is 10mm, the number of the support frame 2 is two, and they are respectively fixed to the horizont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com