Polyester polyethylene alloy plastic pipe and preparation method thereof

A technology of alloy plastics and polyethylene, applied in the field of material processing, can solve the problems of not having a good solution for compatibilizer and preparation process, not processing pipe products, and general mechanical properties of materials, so as to reduce performance degradation and reduce The effect of high energy and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

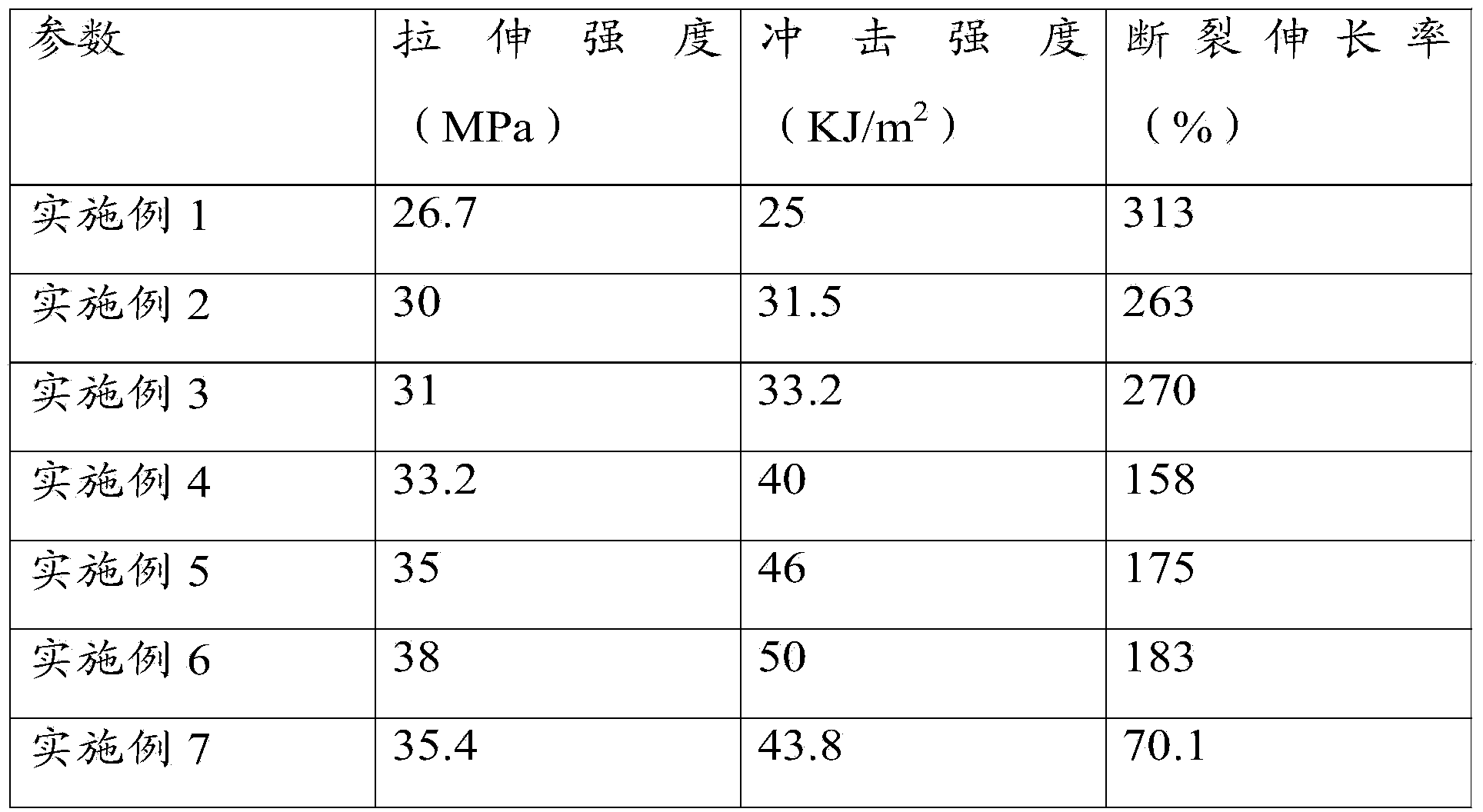

Examples

Embodiment 1

[0045] PET bottle flake preparation: use the PET cleaning production line of Zhangjiagang Lianguan Environmental Protection Technology Co., Ltd. to crush, clean and dry the recycled PET bottles to obtain PET bottle flakes;

[0046] PE preparation: crush and clean the recycled PET bottle caps (material is PE), PE film, PE hollow barrels, etc.;

[0047] Formulation selection: The weight ratio of PET to PE is 1:1, the addition amount of compatibilizer is 10% of the total weight of PET and PE, and the addition amount of antioxidant is 3% of the total weight of PET and PE; among them, compatible The agent is maleic anhydride grafted PE, and the antioxidant is antioxidant 1076;

[0048] Put the PET, PE, compatibilizer and antioxidant in a high-speed mixer, stir and mix together for 8 minutes, the stirring speed is 180r / min, and the temperature is 22°C;

[0049] Then put the mixture in a co-rotating twin-screw extruder to melt and extrude, where the barrel temperature is 200℃, 230℃, 260℃, 28...

Embodiment 2

[0052] PET bottle flake preparation: use the PET cleaning production line of Zhangjiagang Lianguan Environmental Protection Technology Co., Ltd. to pulverize, clean and dry to obtain PET bottle flakes;

[0053] PE preparation: pulverize and clean recycled PET bottle caps (material is PE), PE film, PE hollow barrels, etc.;

[0054] Formula selection: The weight ratio of PET and PE is 2:1, the addition amount of compatibilizer is 8% of the total weight of PET and PE, and the addition amount of antioxidant is 2% of the total weight of PET and PE; among them, compatible The agent is maleic anhydride grafted POE, and the antioxidant is antioxidant 1010;

[0055] Put the PET, PE, compatibilizer and antioxidant in a high-speed mixer, stir and mix together for 5 minutes at a speed of 200r / min and a temperature of 25°C;

[0056] Then put the mixture in a co-rotating twin-screw extruder to melt and extrude, where the barrel temperature is 180℃, 210℃, 230℃, 260℃, 270℃, and the die temperature is...

Embodiment 3

[0059] PET bottle flake preparation: use the PET cleaning production line of Zhangjiagang Lianguan Environmental Protection Technology Co., Ltd. to crush, clean and dry the recycled PET bottles to obtain PET bottle flakes;

[0060] PE preparation: pulverize and clean recycled PET bottle caps (material is PE), PE film, PE hollow barrels, etc.;

[0061] Formula selection: The weight ratio of PET and PE is 2:1, the addition amount of compatibilizer is 8% of the total weight of PET and PE, and the addition amount of antioxidant is 2% of the total weight of PET and PE; among them, compatible The agent is maleic anhydride grafted POE, and the antioxidant is antioxidant 1076;

[0062] Put the PET, PE, compatibilizer and antioxidant in a high-speed mixer, stir and mix together for 5 minutes at a speed of 200r / min and a temperature of 25°C;

[0063] Then put the mixture in a co-rotating twin-screw extruder to melt and extrude, where the barrel temperature is 180℃, 210℃, 230℃, 260℃, 270℃, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com