Emulsified oil and applications thereof

A technology of emulsified oil and emulsifier, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of high environmental hazards and poor stability, and achieve the effects of good mildew resistance, good stability, and superior emulsification performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

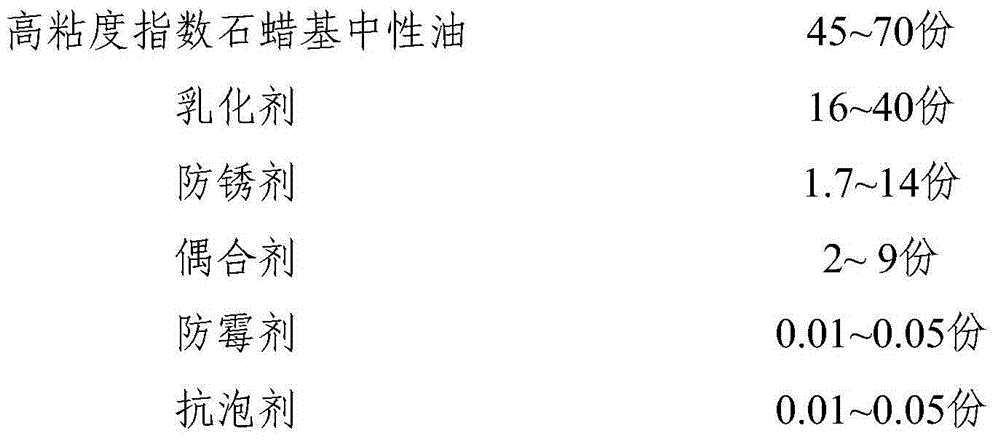

[0029] The composition of emulsified oil in the present embodiment is shown in the table below:

[0030] serial number

[0031] 7

[0032] The preparation process of the emulsified oil in this example is as follows: first add a high viscosity index paraffin-based neutral oil, heat it to 55-65°C under stirring, and add other components in turn while stirring at a constant speed. After one component, stir until evenly mixed before adding the next component. Among them, there is no special requirement for the specific addition sequence of each component of the emulsified oil for mine use, and it can be added according to the actual situation. After all the components are added, stir at a constant temperature of 55-65° C. for 3-5 hours.

Embodiment 2

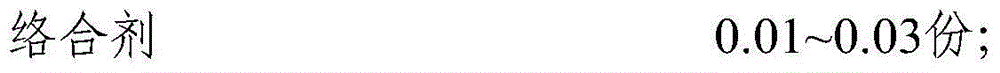

[0034] The composition of emulsified oil in the present embodiment is shown in the table below:

[0035] serial number

[0036] The preparation process is the same as in Example 1.

Embodiment 3

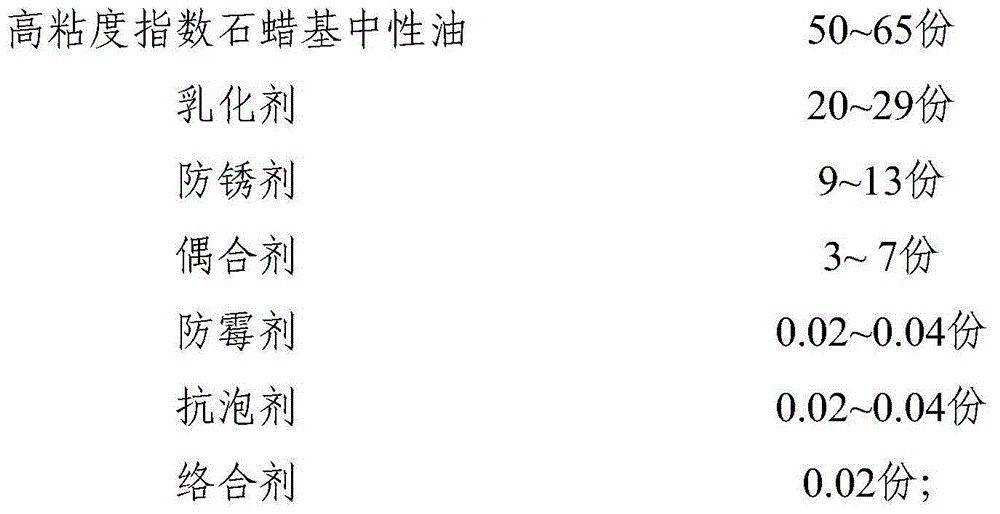

[0038] The composition of emulsified oil in the present embodiment is shown in the table below:

[0039] serial number

[0040] 2

[0041] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com