Ladle refining auxiliary argon blowing apparatus

A technology of ladle refining and steel sleeve, which is applied in the field of auxiliary argon blowing device for ladle refining, can solve the problems of reducing the service life of the ladle, the residual height of the breathable brick is too short, and the consumption of large electric energy and alloys, etc. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be explained in more detail through the following examples, and the present invention is not limited to the following examples; the purpose of disclosing the present invention is intended to protect all changes and improvements within the scope of the present invention.

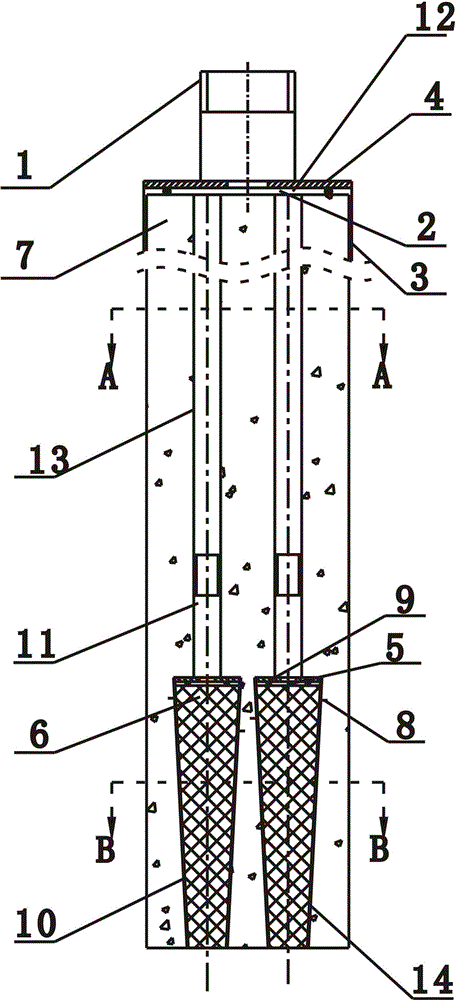

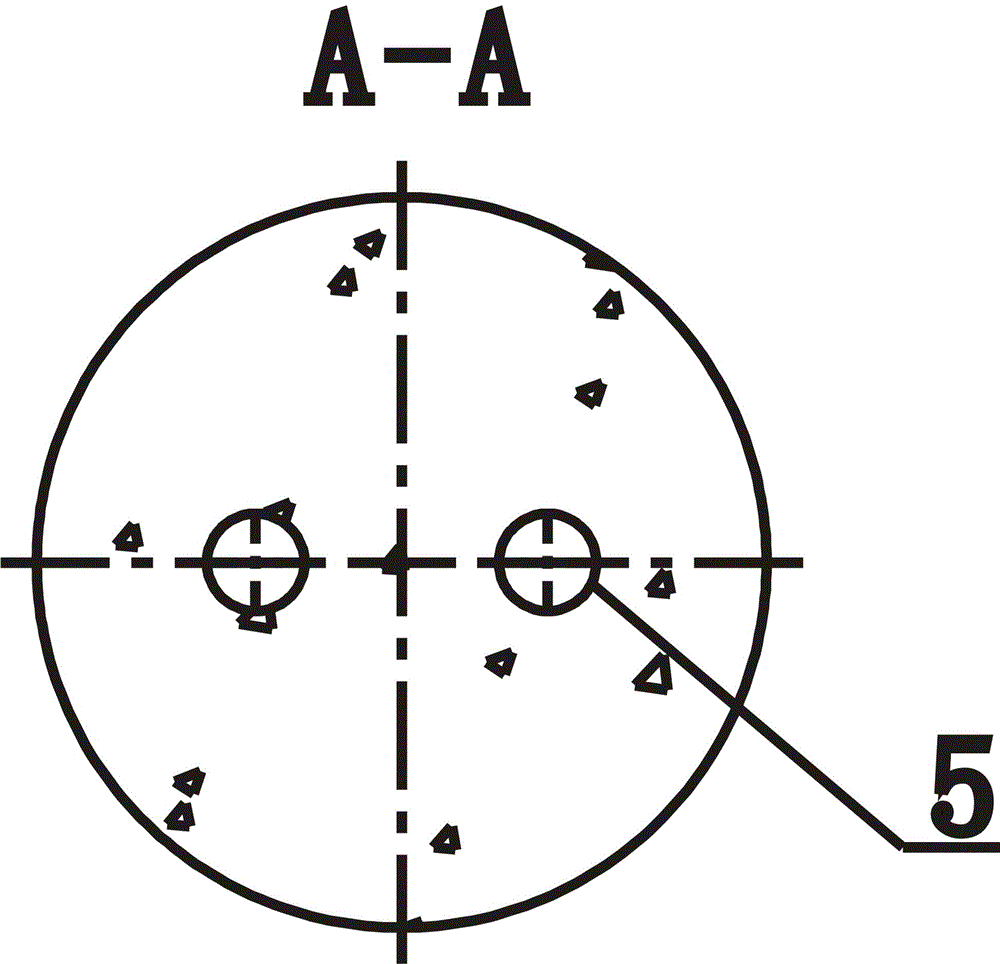

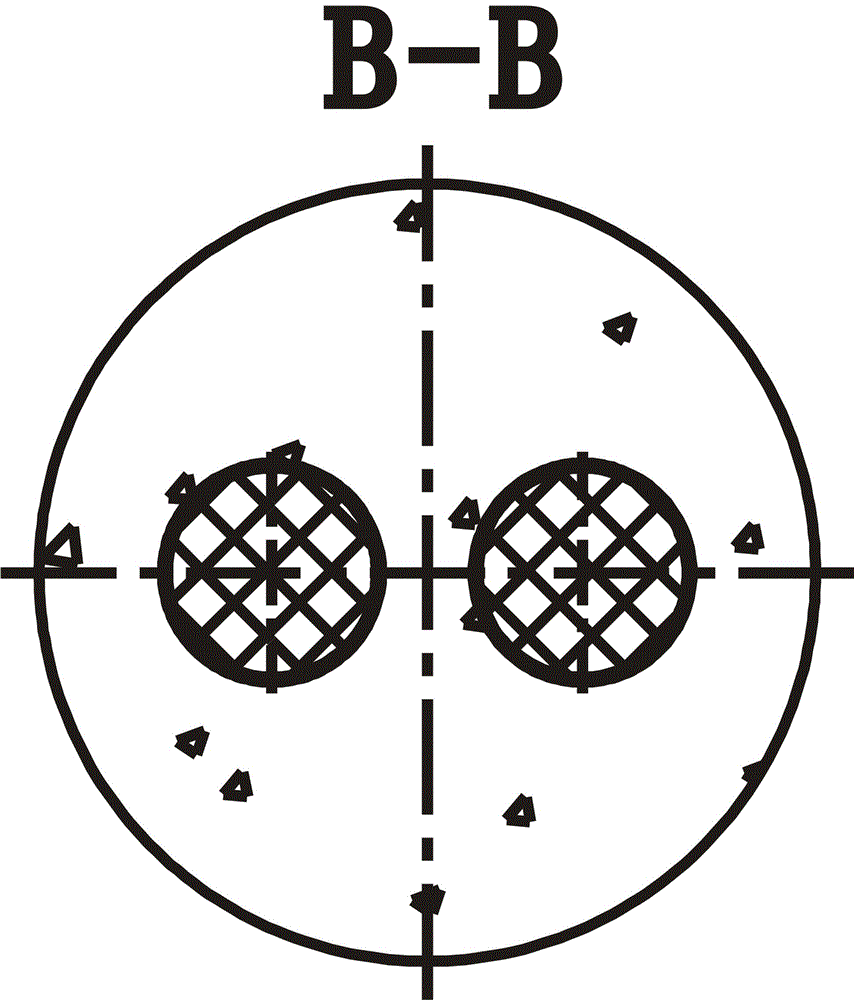

[0027] The ladle refining auxiliary argon blowing device includes a metal air pipe A1, a steel sleeve A2, a metal cover plate A4, a metal pipe 13, a ventilating brick 6, a refractory castable 7 and a metal air pipe B11, and the upper part of the refractory castable 7 is provided with There are a plurality of metal pipes 13, and a plurality of air-permeable bricks 6 are arranged at the lower part of the refractory castable 7. The metal pipes 13 and the air-permeable bricks 6 are connected by a metal air pipe B11, and the steel sleeve A2 is covered with a refractory castable. On the upper end surface and the upper outer edge surface of the material 7, a metal cover plate A4 is pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com