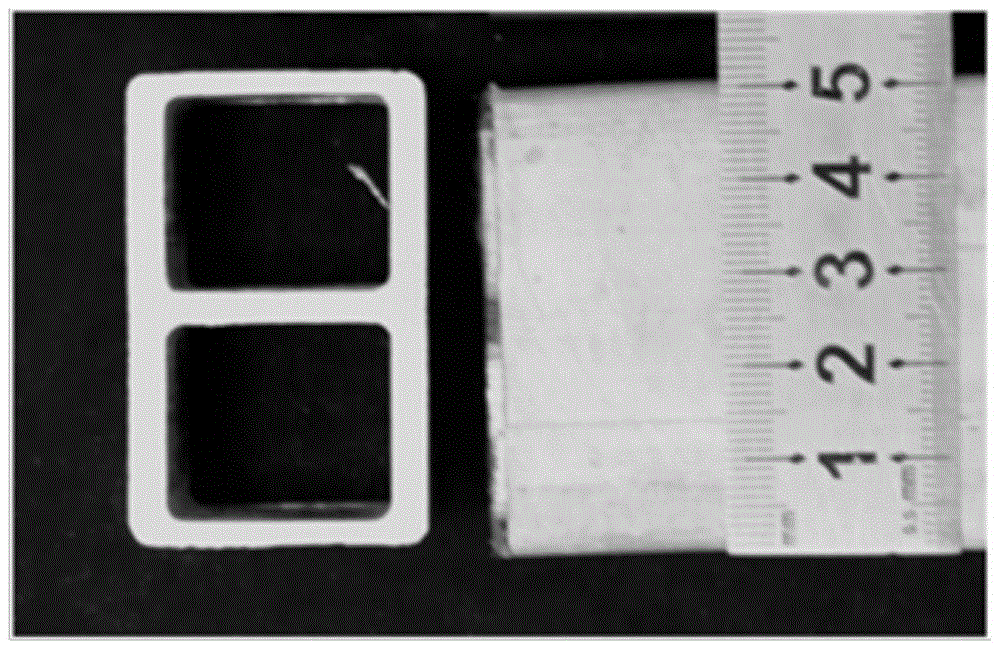

Magnesium alloy pipe material for high-performance automobile anti-collision bar and manufacturing method thereof

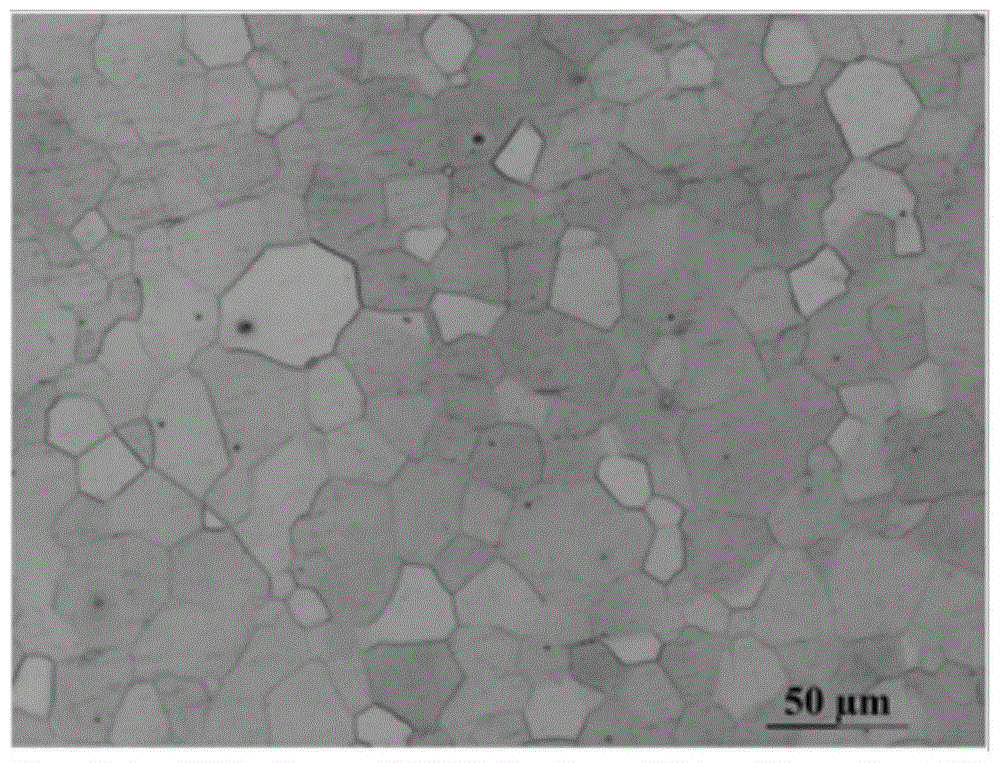

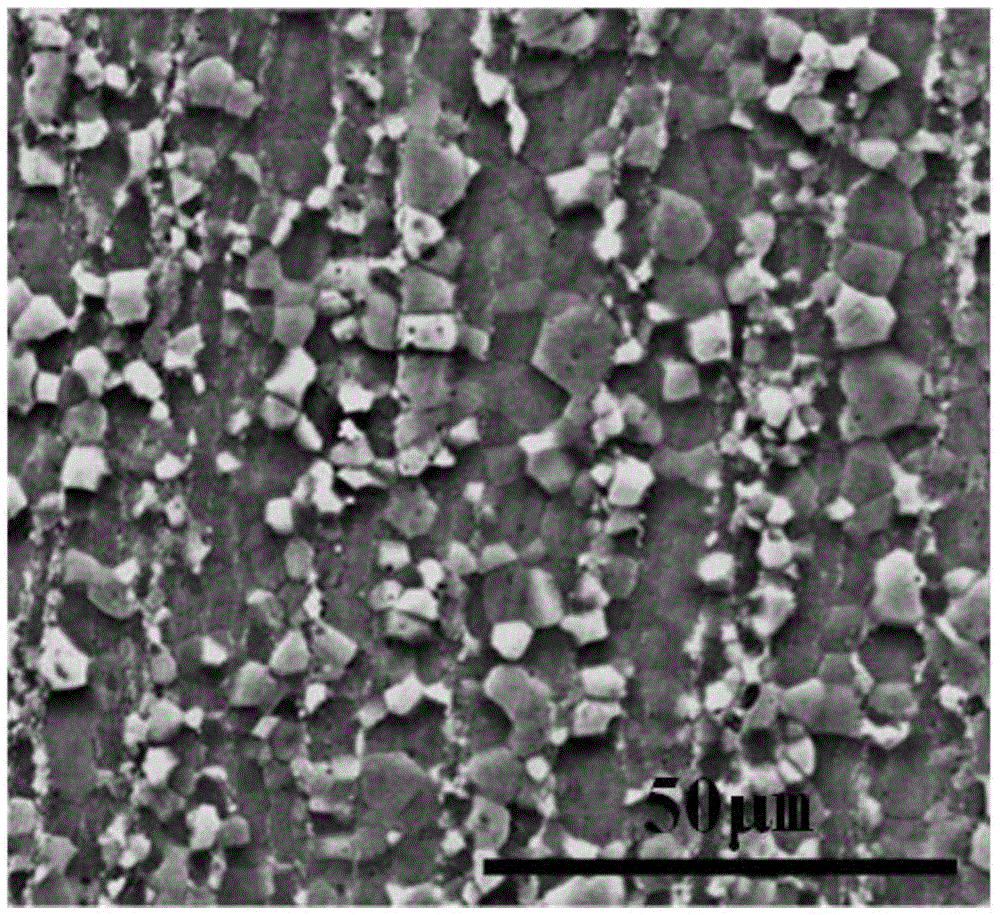

A technology for automobile crash bars and magnesium alloys, applied in the field of metal material processing, can solve the problems of poor plastic deformation ability of high-strength magnesium alloys, and achieve the effects of uniform grain morphology and good uniformity of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. According to the mass fraction of 8% Gd, 3% Y, 0.5% Zr, 88.5% Mg and unavoidable impurities, the semi-continuous casting method is used to prepare a Φ300mm magnesium alloy semi-continuous ingot, and the ingot is cut Each ingot block with a length of 500 mm is formed. The method of semi-continuous ingot casting is as follows: firstly preheat each master alloy of Mg-Gd, Mg-Y, Mg-Zr and pure Mg to 180-220 ° C; Magnesium is placed in a protective gas (V SF6 :V CO2 =1:99) in a well-type resistance crucible furnace, when the temperature of the magnesium liquid reaches 720-740°C, add Mg-Gd and Mg-Y directly into the magnesium liquid in turn, and wait for the Mg-Gd and Mg-Y to melt Afterwards, raise the temperature of the magnesium melt to 760-780°C, and add Mg-Zr; after the Mg-Zr melts, skim off the scum on the surface, and stir for 10 minutes; then raise the temperature of the magnesium melt to 780-800°C, and keep it warm for 20 After ~30 minutes, the molten magnesium is...

Embodiment 2

[0036] 1. According to the mass fraction of 8% Gd, 3% Y, 0.5% Zr, 88.5% Mg and unavoidable impurities, the semi-continuous casting method is used to prepare a Φ300mm magnesium alloy semi-continuous ingot, and the ingot is cut into ingot blocks each with a length of 500 mm; the method of semi-continuous ingot casting is as follows: firstly, each master alloy of Mg-Gd, Mg-Y, Mg-Zr and pure Mg are preheated to 180-220°C; then the pure Magnesium is placed in a protective gas (V SF6 :V CO2 =1:99) in a well-type resistance crucible furnace, when the temperature of the magnesium liquid reaches 720-740°C, add Mg-Gd and Mg-Y directly into the magnesium liquid in turn, and wait for the Mg-Gd and Mg-Y to melt Afterwards, raise the temperature of the magnesium melt to 760-780°C, and add Mg-Zr; after the Mg-Zr melts, skim off the scum on the surface, and stir for 10 minutes; then raise the temperature of the magnesium melt to 780-800°C, and keep it warm for 20 After ~30 minutes, the molt...

Embodiment 3

[0041] 1. According to the mass fraction of 8% Gd, 3% Y, 0.5% Zr, 88.5% Mg and unavoidable impurities, the semi-continuous casting method is used to prepare a Φ300mm magnesium alloy semi-continuous ingot, and the ingot is cut into ingot blocks each with a length of 500 mm; the method of semi-continuous ingot casting is as follows: firstly, each master alloy of Mg-Gd, Mg-Y, Mg-Zr and pure Mg are preheated to 180-220°C; then the pure Magnesium is placed in a protective gas (V SF6 :V CO2 =1:99) in a well-type resistance crucible furnace, when the temperature of the magnesium liquid reaches 720-740°C, add Mg-Gd and Mg-Y directly into the magnesium liquid in turn, and wait for the Mg-Gd and Mg-Y to melt Afterwards, raise the temperature of the magnesium melt to 760-780°C, and add Mg-Zr; after the Mg-Zr melts, skim off the scum on the surface, and stir for 10 minutes; then raise the temperature of the magnesium melt to 780-800°C, and keep it warm for 20 After ~30 minutes, the molt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com