A kind of lead alloy anode plate for electrochemical metallurgy and preparation method thereof

A lead alloy, anode plate technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of uneven distribution, segregation, coarse grains, etc., and achieve the effect of reducing corrosion rate, prolonging service life, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

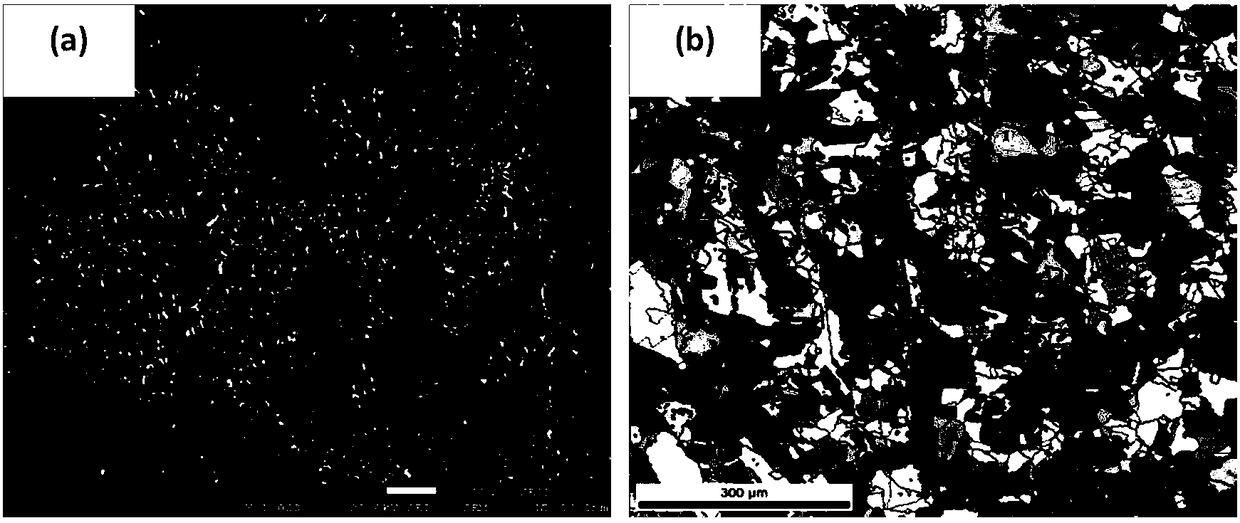

[0025] The chemical composition is: silver 0.85wt%, and the rest is lead alloy liquid into a water-cooled iron mold with a specification of 600×480×60mm, and the surface layer of the alloy liquid in the water-cooled iron mold is completely solidified, and the temperature in the center of the surface layer is cooled to Demould at 220°C to obtain semi-solidified lead alloy ingots; then use a twin-roll mill to reduce the amount of passes by 60→54→48→42→36→30→26→22→18→14→10→8, The semi-solidified lead alloy ingot is pressed down multiple times to obtain a lead-silver alloy anode plate with a size of 450×580×8mm, and its surface appearance is as follows: figure 1 As shown in -a, the OIM diagram is as follows figure 1 -b shown.

[0026] Depend on figure 1 -a It can be seen that, compared with the lead-silver alloy anode plate prepared by the conventional process, the silver-rich phase of the lead-silver alloy anode plate prepared by this method is dispersedly distributed on the su...

Embodiment 2

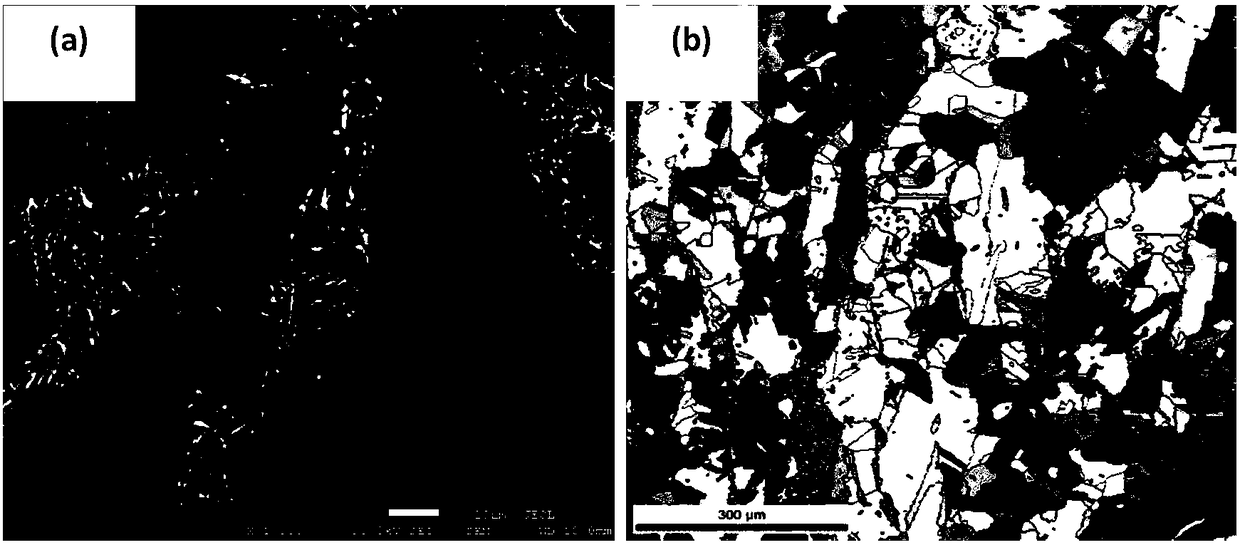

[0029] The chemical composition is: silver 0.20wt%, calcium 0.08wt%, strontium 0.05wt%, and the rest is lead alloy liquid into a water-cooled iron mold with a specification of 600×480×60mm, and the alloy liquid in the water-cooled iron mold is The surface layer is completely solidified, and the temperature of the central area of the surface layer is cooled to 180°C, and the mold is demoulded to obtain a semi-solidified lead alloy ingot; then use a two-roll mill to press 60→54→48→43→38→34→30→26→22→18→ 14 → 11 → 8 → 7 → 6 pass reduction, the semi-solidified lead alloy ingot is subjected to multi-pass reduction to obtain a lead-silver-calcium-strontium alloy anode plate with a size of 450×580×6 mm.

[0030] The electrochemical performance of the lead-silver-calcium-strontium alloy anode plate prepared by this method in the zinc electrowinning process was detected, and the detection process conditions were as described in Example 1; the detection results are shown in Table 1.

Embodiment 3

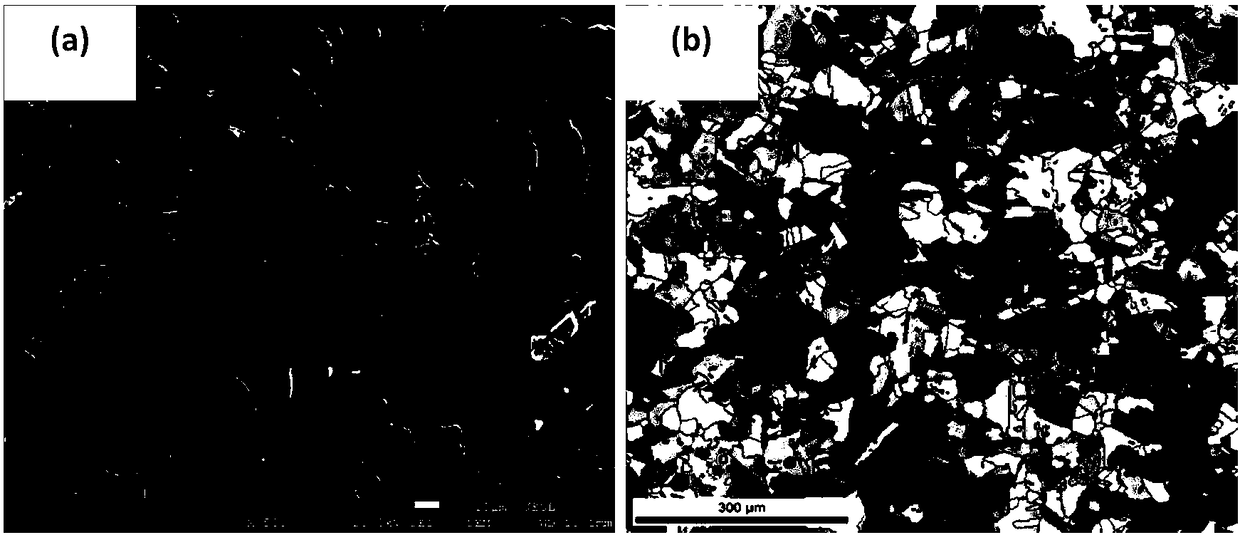

[0037] The chemical composition is: 0.08wt% of calcium, 1.70wt% of tin, 0.005wt% of aluminum, and the rest is lead. The surface layer is completely solidified, and when the temperature of the central area of the surface layer is cooled to 150°C, the mold is demoulded to obtain a semi-solidified lead alloy ingot; 14 → 10 → 8 pass reduction, multi-pass reduction of semi-solidified lead alloy ingot to obtain a lead-calcium-tin-aluminum alloy anode plate with a size of 450×580×8mm, and its surface appearance is as follows image 3 As shown in -a, the OIM diagram is as follows image 3 -b shown.

[0038] Depend on image 3 -a It can be seen that, compared with the lead-calcium-tin-aluminum alloy anode plate prepared by the conventional process, there are a large number of deformation twins on the surface of the lead-calcium-tin-aluminum alloy anode plate prepared by this method. Depend on image 3 -b It can be seen that the surface of the lead-calcium-tin-aluminum alloy anode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com