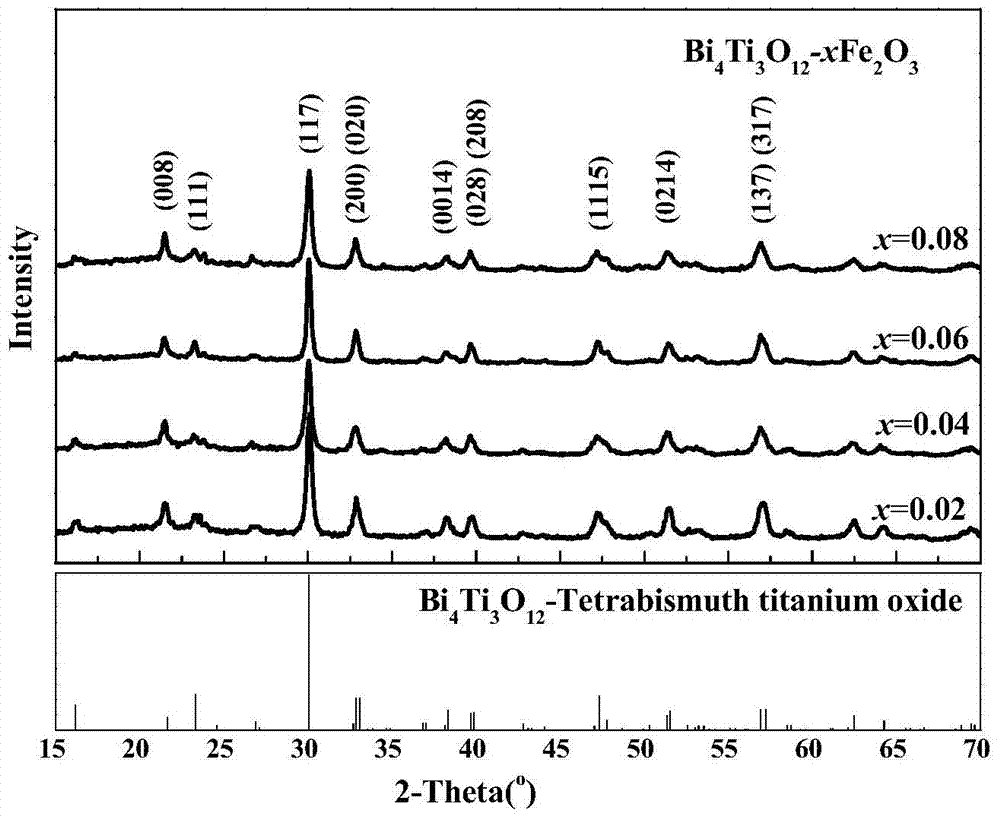

A low loss, high resistivity bi 4 ti 3 o 12 Preparation method of lead-free piezoelectric ceramics

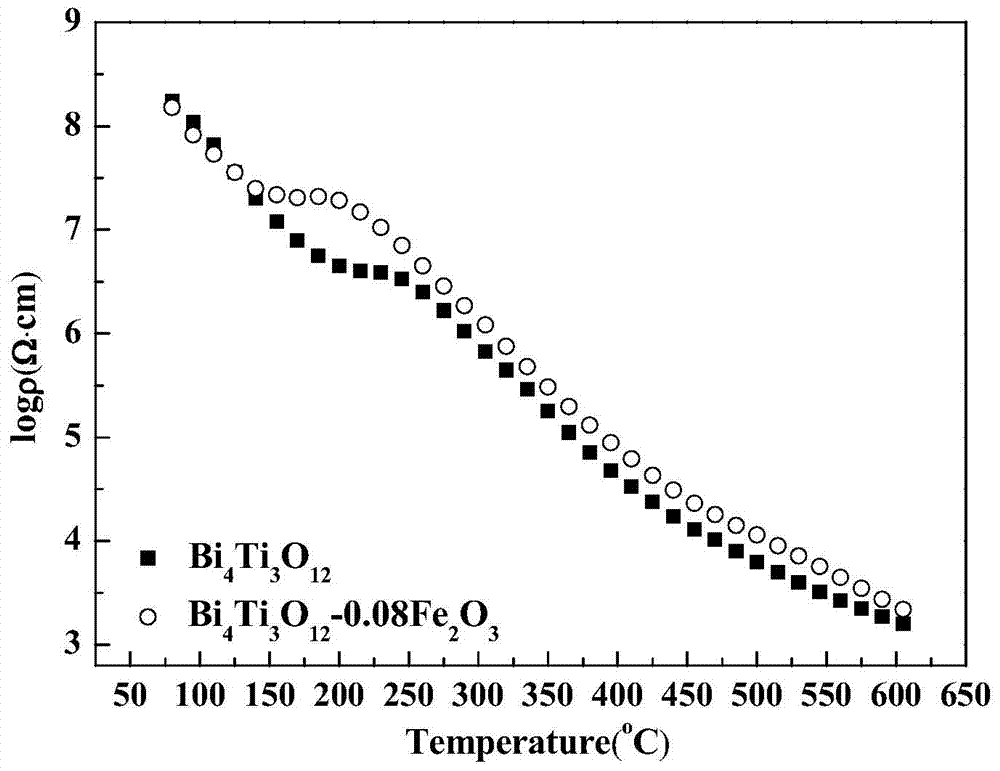

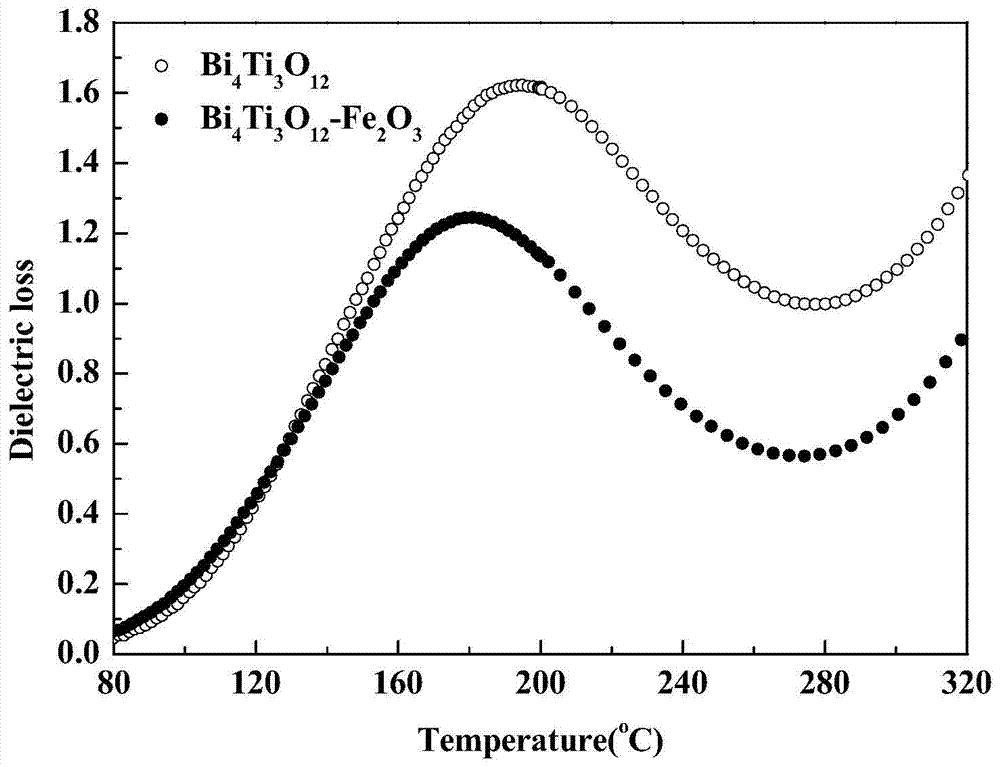

A high-resistivity, lead-free piezoelectric technology, applied in the field of ferroelectric ceramics, can solve the problems of material depolarization, component heating damage, loss of piezoelectric performance, etc., achieve grain refinement, and reduce leakage current. , the effect of uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of the present invention specifically comprises:

[0025] Step 1: Bismuth oxide Bi 2 o 3 and titanium dioxide TiO 2According to the molar ratio (2~3):(3~4), powder A is obtained after mixing the ingredients, according to the mass ratio, powder A: zirconia ball stone: distilled water = 1: (1~8): (0.8~1.2 ), after mixing, ball mill in a ball mill tank for 4 to 8 hours;

[0026] Step 2: Dry the powder A after ball milling in step 1 in a constant temperature oven at 60-80°C for 8-24 hours, grind and briquette, and pre-fire in a muffle furnace. The pre-fire conditions are: In the process, according to the heating and cooling rates of 3-6°C / min, firstly, the temperature was raised from room temperature to 400°C and kept for 10 minutes; then the temperature was raised from 400°C to 800-850°C and kept for 2-3 hours; Cool down to 400°C; finally cool down to room temperature with the furnace; grind again to get Bi 4 Ti 3 o 12 Powder;

[0027] Step 3...

Embodiment 1

[0032] Step 1: Bismuth oxide (Bi 2 o 3 ) and titanium dioxide (TiO 2 ) is accurately weighed according to the molar ratio of 2:3; the weighed and mixed material is used as the material according to the mass ratio: ball: water = 1:1:1.2 and put into the ball mill jar for 4 hours of ball milling process;

[0033] Step 2: After the ball milling is completed, put it in a constant temperature box and dry it at 70°C for 18 hours; take the material and grind it, press it into a block, and pre-fire it in a muffle furnace. The heating rate is 4°C / min, and the temperature is kept for 10 minutes; then the temperature is raised from 400°C to 800°C, the heating rate is 5°C / min, and the temperature is kept for 2 hours; then the temperature is lowered from 800°C to 400°C, and the cooling rate is 5°C / min; The furnace was cooled to room temperature; grinding again gave Bi 4 Ti 3 o 12 Powder;

[0034] Step 3: Bi obtained after calcining and grinding 4 Ti 3 o 12 Add Fe to the powder 2 ...

Embodiment 2

[0037] Step 1: Bismuth oxide (Bi 2 o 3 ) and titanium dioxide (TiO 2 ) is accurately weighed according to the molar ratio of 2:4; the weighed mixed material is used as the material according to the mass ratio: ball: water = 1:8:1.2, and put it into a ball mill jar for 4 hours of ball milling;

[0038] Step 2: After the ball milling is completed, put it in a constant temperature box and dry it at 80°C for 8 hours; take the material and grind it, press it into a block, and pre-fire it in a muffle furnace. 3~6°C / min, firstly, the temperature is raised from room temperature to 400°C, and kept for 10 minutes; then the temperature is raised from 400°C to 820°C, and held for 3 hours; 4 Ti 3 o 12 Powder;

[0039] Step 3: Bi obtained after calcining and grinding 4 Ti 3 o 12 Add Fe to the powder 2 o 3 , Bi 4 Ti 3 o 12 powder and added Fe 2 o 3 The molar ratio is 1:0.01; put the weighed and mixed material into the material according to the mass ratio: ball: water = 1:8:1.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com